BLOG

How Top Manufacturers Use AI-Powered Charging Stations to Improve Fleet Uptime for Autonomous Robots

Table of contents

What role does AI play in modern robot charging stations?

Artificial intelligence is transforming how autonomous robots manage energy. Traditional charging stations operate on fixed cycles or manual scheduling, but AI-powered systems use data-driven insights to determine when, how, and how much to charge each robot. These stations monitor usage patterns, predict battery needs, and optimize charging sessions to minimize downtime. Instead of robots waiting in line or receiving unnecessary full charges, AI ensures energy is distributed efficiently across the fleet.

AI also helps extend battery life by applying adaptive charging methods. By learning from each robot’s performance history, stations can adjust charging rates to reduce wear and overheating. For businesses operating fleets across logistics, manufacturing, or delivery, AI-powered charging introduces a level of intelligence that wasn’t possible with older models. The result is safer, more efficient, and more cost-effective operations.

Top Benefits

- Smarter energy management through predictive analytics

- Extended battery lifespan with adaptive charging cycles

- Reduced downtime by eliminating unnecessary charging delays

Best Practices

- Choose stations with built-in AI load-balancing software

- Integrate charging data with fleet management dashboards

- Regularly update AI algorithms for optimal performance

AI-powered charging stations shift robot operations from reactive to proactive, ensuring fleets stay charged, available, and productive with minimal human oversight.

(Suggested Links: Battery Chargers | Innovations in Medical Power Supply Design)

How do AI-powered stations reduce downtime for autonomous fleets?

Downtime is the enemy of productivity in autonomous robotics. When robots sit idle waiting for charging slots, operational efficiency drops. AI-powered charging stations solve this by automatically scheduling charging based on real-time demand. Algorithms predict which robots need immediate charging and which can wait, preventing bottlenecks at docking points. This dynamic scheduling reduces waiting time and keeps fleets operational longer.

Another advantage is predictive maintenance. AI continuously monitors charging patterns, flagging anomalies that could signal battery degradation or hardware issues. By addressing these early, operators avoid sudden breakdowns that would take robots offline. In industries where uptime is mission-critical, such as e-commerce logistics or hospital robotics, this predictive capability ensures reliability while reducing costs tied to emergency repairs or unplanned downtime.

Top Benefits

- Shorter charging queues with intelligent scheduling

- Early detection of battery or charger issues

- Improved fleet utilization through predictive insights

Best Practices

- Monitor charging analytics for performance trends

- Create fleet-wide charging schedules informed by AI insights

- Pair AI systems with remote alerts for proactive intervention

By automating both scheduling and monitoring, AI-powered charging stations reduce downtime while giving operators valuable visibility into fleet health.

(Suggested Links: Open-Frame Power Supplies | PoE Injectors)

What data do AI systems analyze to optimize charging?

AI-powered charging stations thrive on data. They track each robot’s energy usage, charging history, duty cycles, and even environmental factors such as temperature or load weight. This information feeds into machine learning models that predict when a robot will need power and how much charging it requires. By analyzing patterns across the fleet, AI identifies opportunities to stagger charging sessions, preventing simultaneous downtime.

Data also helps protect battery health. By monitoring voltage, current, and heat during charging, AI adjusts output to match safe parameters. Over time, this data builds a performance baseline, making it easier to detect anomalies and prevent failures. For large fleets, the aggregation of this data also provides valuable insights into energy costs, helping companies optimize electricity consumption.

Top Benefits

- Improved charging efficiency through predictive modeling

- Enhanced battery protection with real-time monitoring

- Reduced energy costs from optimized charging schedules

Best Practices

- Use stations with IoT-enabled sensors for granular data collection

- Integrate charging analytics with enterprise dashboards

- Apply machine learning models to detect anomalies early

Data-driven charging transforms stations from simple power providers into intelligent fleet management tools. By using AI to analyze real-time and historical performance, businesses gain both safety and efficiency.

(Suggested Links: USB-C PD Adapters | Internal Power Supply Guide)

CLIENT'S QUOTE

"Phihong’s PoE solutions have made a huge difference for us! Our network runs more efficiently, and we’ve seen real cost savings. We couldn’t be happier!"

AI-driven predictive maintenance improves reliability

Predictive maintenance is one of the most valuable applications of AI in robotic charging. Instead of waiting for a failure to occur, AI-powered stations continuously analyze battery performance, charge cycles, and power delivery efficiency. They detect subtle patterns—such as slower charging times or abnormal heat levels—that may indicate early signs of wear. By flagging these issues, operators can replace or service components before they disrupt operations.

This predictive approach helps organizations avoid costly downtime. Instead of pulling robots from service unexpectedly, maintenance can be scheduled strategically during low-demand periods. Over time, predictive insights also extend battery and charger lifespan by ensuring components are not stressed beyond their limits. For manufacturers and logistics operators, this level of foresight reduces both repair expenses and operational risk, while improving overall fleet reliability.

Top Benefits

- Identifies failures before they cause downtime

- Extends the service life of batteries and chargers

- Reduces maintenance costs with proactive scheduling

Best Practices

- Track battery performance data across all robots

- Set automated alerts for early fault detection

- Align service schedules with fleet demand cycles

By using predictive maintenance powered by AI, companies minimize unexpected breakdowns and improve uptime. This proactive approach helps robotic fleets remain dependable and cost-effective in demanding industries.

(Suggested Links: Battery Chargers | PoE Injectors)

Smart load balancing optimizes energy usage

Energy management is another critical challenge when running large fleets of autonomous robots. Without proper control, charging dozens of robots simultaneously can overload circuits or spike electricity costs. AI-powered stations solve this by applying smart load balancing. They distribute power across multiple units based on real-time demand, ensuring no single circuit is overburdened. This keeps energy costs predictable and prevents interruptions to operations.

Smart load balancing also improves sustainability. By charging robots during off-peak hours or reducing load when energy demand is high, companies lower their overall carbon footprint. AI ensures that energy is consumed efficiently, balancing operational uptime with environmental responsibility. For industries under pressure to meet both performance and sustainability goals, this dual benefit makes AI-powered charging stations especially attractive.

Top Benefits

- Prevents overloads and improves electrical safety

- Reduces electricity costs through optimized charging cycles

- Supports sustainability initiatives with smarter energy use

Best Practices

- Configure AI systems to prioritize off-peak charging

- Monitor facility power usage to fine-tune load distribution

- Pair AI load balancing with renewable energy sources

Smart load balancing ensures robots get the power they need without straining resources. By combining safety with sustainability, AI-powered stations deliver efficiency gains that go beyond uptime alone.

(Suggested Links: Open-Frame Power Supplies | USB-C PD Adapters)

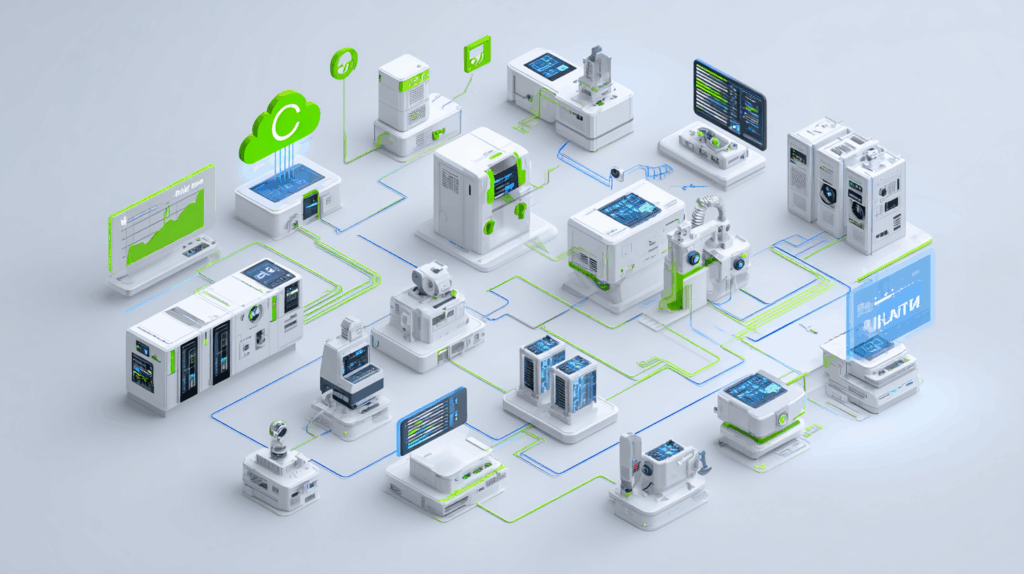

Seamless integration with fleet management systems

The best AI-powered charging stations don’t operate in isolation—they integrate seamlessly with fleet management platforms. This allows charging data to be combined with scheduling, navigation, and performance metrics, giving operators a holistic view of their fleets. Instead of managing energy separately, managers can make informed decisions about deployment and charging in one place.

Integration also unlocks advanced automation. Robots can be directed to charge only when capacity is available, or when their tasks are complete, avoiding unnecessary downtime. Over time, this reduces manual oversight and ensures robots are always available for mission-critical tasks. For large operations, the ability to connect charging stations directly into existing software ecosystems saves time, improves visibility, and enhances decision-making.

Top Benefits

- Unified view of fleet and charging data

- Automation reduces manual intervention and oversight

- Better resource allocation with data-driven insights

Best Practices

- Select stations compatible with existing fleet management software

- Ensure data security when integrating across systems

- Use integration to inform long-term fleet optimization strategies

By integrating charging data with fleet management systems, companies gain control and visibility across their entire operation. This seamless connection ensures robots remain productive, reliable, and ready for action.

(Suggested Links: Internal Power Supply Guide | Battery Chargers)

How Phihong supports AI-powered charging for robotics

Phihong continues to innovate in power solutions by designing products that align with the growing demand for AI-enabled charging infrastructure. With decades of experience in manufacturing safe, efficient, and compliant power systems, Phihong offers the building blocks that make intelligent charging stations possible. Their portfolio includes high-efficiency battery chargers, USB-C PD adapters, and ruggedized power supplies that support the unique demands of autonomous fleets.

By integrating IEC, UL, and CE standards into every design, Phihong ensures their products are globally compliant and ready for deployment in diverse industries. Their solutions often feature built-in protections against over-voltage, over-current, and thermal stress—key requirements for AI systems that rely on safe and stable charging platforms.

Energy efficiency is also central to Phihong’s approach. Their products help reduce heat and wasted power, which supports AI-driven optimization strategies while lowering operational costs. Whether powering delivery robots, healthcare assistants, or industrial fleets, Phihong provides the reliable, scalable solutions businesses need to maximize uptime. For organizations looking to integrate AI into their charging infrastructure, Phihong delivers both the technology and the trustworthiness to support long-term growth.

(Suggested Links: Battery Chargers | Contact Phihong)

Contact Our Team Today!

Our dedicated sales team and international partners are prepared to support you with your latest projects and initiatives globally.

How Phihong supports safety in robot charging solutions

Phihong has a long history of delivering power products that balance performance, compliance, and safety. For robotic charging stations, Phihong integrates internationally recognized standards such as IEC, UL, CE, and RoHS into the design and manufacturing process. This ensures that every solution is tested against rigorous benchmarks before reaching customers. By focusing on global compliance, Phihong makes it easier for businesses to scale their robotic fleets across regions without worrying about safety certification gaps.

In addition to compliance, Phihong emphasizes durability and reliability. Many of their products include built-in protections against over-voltage, over-current, and thermal overload, reducing the risk of downtime or equipment damage. Ruggedized designs also ensure that charging solutions function reliably in challenging environments such as outdoor logistics hubs or healthcare facilities with strict cleanliness standards.

Energy efficiency is another hallmark of Phihong’s solutions. By designing high-efficiency power supplies and charging systems, Phihong reduces heat buildup and supports sustainable operations. Customers benefit from lower long-term costs, improved safety, and extended product lifespans. Whether powering autonomous delivery robots, industrial fleets, or medical devices, Phihong provides charging solutions that combine safety, compliance, and reliability.

(Suggested Links: Battery Chargers | Contact Phihong)

FAQ

What makes AI-powered charging stations different from traditional systems?

Traditional charging stations operate on fixed schedules or manual plug-ins, often leading to inefficiencies. Robots may sit idle waiting for slots, or they may receive unnecessary full charges that shorten battery life. AI-powered charging stations, by contrast, use data and machine learning to optimize the entire process. They monitor each robot’s usage patterns, battery health, and task requirements, then deliver charging sessions tailored to actual needs.

This smart approach eliminates wasted energy and reduces downtime. AI stations can also dynamically schedule charging, so fleets don’t bottleneck around limited docks. By analyzing historical and real-time data, they predict when each robot will need power and stagger sessions accordingly. The result is smoother operations, longer battery lifespans, and better energy efficiency.

Another differentiator is predictive maintenance. AI systems detect anomalies in charging cycles, such as unusual heat levels or slower charging rates, and flag them before they become major issues. This proactive monitoring reduces the likelihood of unexpected breakdowns. In essence, AI-powered stations turn charging from a passive necessity into an active strategy that enhances uptime and reliability for autonomous fleets.

How do AI-powered charging stations improve fleet uptime?

Fleet uptime depends on keeping robots operational with minimal delays. AI-powered charging stations achieve this by intelligently distributing power where it’s needed most. Instead of robots waiting for access, AI manages the queue, directing units to available slots or staggering charges to prevent bottlenecks. This ensures that robots spend more time working and less time idle.

AI also reduces downtime by optimizing charge levels. Not every robot needs a full charge at every session—sometimes a partial charge is enough to complete a task. By recognizing these scenarios, AI minimizes charging time while still keeping robots productive. Over the long run, this efficiency leads to higher utilization rates across fleets.

Additionally, predictive analytics prevent sudden failures. If a station detects unusual battery behavior, it alerts operators before the robot goes offline. This foresight allows for scheduled maintenance rather than emergency downtime. For industries where uptime directly affects customer satisfaction—like e-commerce deliveries or hospital robotics—AI-powered charging is a critical tool for maintaining continuous operations.

What types of data do AI-powered charging stations monitor?

AI-powered stations collect a wide range of data points to optimize performance. These include voltage, current, temperature, charge duration, and battery cycle counts. Environmental data, such as ambient temperature and humidity, can also be factored into charging decisions. On a broader scale, stations monitor fleet-level metrics like total energy usage, peak demand times, and charging queue patterns.

This information is processed using machine learning models that identify trends and anomalies. For instance, if one robot consistently shows declining battery efficiency, the system can recommend a battery replacement before failure occurs. By comparing data across the fleet, AI also suggests strategies for balancing loads and minimizing costs, such as charging more units during off-peak hours.

Importantly, this data isn’t only about efficiency—it’s also about safety. AI systems use real-time monitoring to prevent overcharging, overheating, or short-circuit risks. By combining operational insights with safety protocols, AI-powered stations provide businesses with both performance improvements and peace of mind. For operators, this level of data visibility helps optimize fleets while protecting valuable assets.

How does AI-driven predictive maintenance save costs?

Predictive maintenance uses AI to anticipate failures before they happen. Charging stations monitor variables such as charging speed, heat levels, and battery response. If patterns suggest a potential issue, the system notifies operators in advance. Addressing these issues early is far less expensive than replacing batteries or dealing with unexpected downtime.

For example, catching an overheating battery early can prevent fire hazards and avoid losing a robot to irreparable damage. By scheduling maintenance proactively, businesses reduce emergency repair costs and minimize disruptions. Predictive insights also extend component lifespans, which reduces capital expenditure over time.

The financial benefits extend beyond direct savings. Predictive maintenance improves customer satisfaction by ensuring reliable operations, especially in industries where uptime is crucial. It also enhances workforce productivity, as employees spend less time dealing with breakdowns. For organizations scaling robotic fleets, predictive maintenance powered by AI is not just a cost-saving measure—it’s a strategic investment in reliability and long-term success.

Why should businesses consider Phihong when adopting AI-powered charging?

Phihong has a proven track record in delivering reliable, compliant, and efficient power solutions. Their portfolio of battery chargers, USB-C PD adapters, and ruggedized power supplies provides the foundation for intelligent charging infrastructure. By designing with IEC, UL, and CE standards in mind, Phihong ensures its products meet the global safety and compliance requirements necessary for AI-driven systems.

Phihong’s solutions integrate well with AI platforms because they already include features like high efficiency, wide input ranges, and built-in protections against over-voltage, over-current, and thermal stress. These are critical for AI systems that rely on stable, accurate data inputs to optimize charging.

Beyond hardware, Phihong supports customers with engineering expertise and documentation, helping businesses deploy charging solutions confidently. Whether powering healthcare assistants, delivery robots, or industrial fleets, Phihong delivers products that combine safety, compliance, and energy efficiency. For companies embracing AI-powered charging, partnering with Phihong means gaining a reliable manufacturer that understands both the technical requirements and the practical challenges of robotics-driven industries.