BLOG

Best Guide to Open-Frame Internal Power Supplies: How to Choose the Right Internal PSU for Industrial Equipment

QUICK LINKS

Why Are Open-Frame Internal Power Supplies Commonly Used in Industrial Equipment?

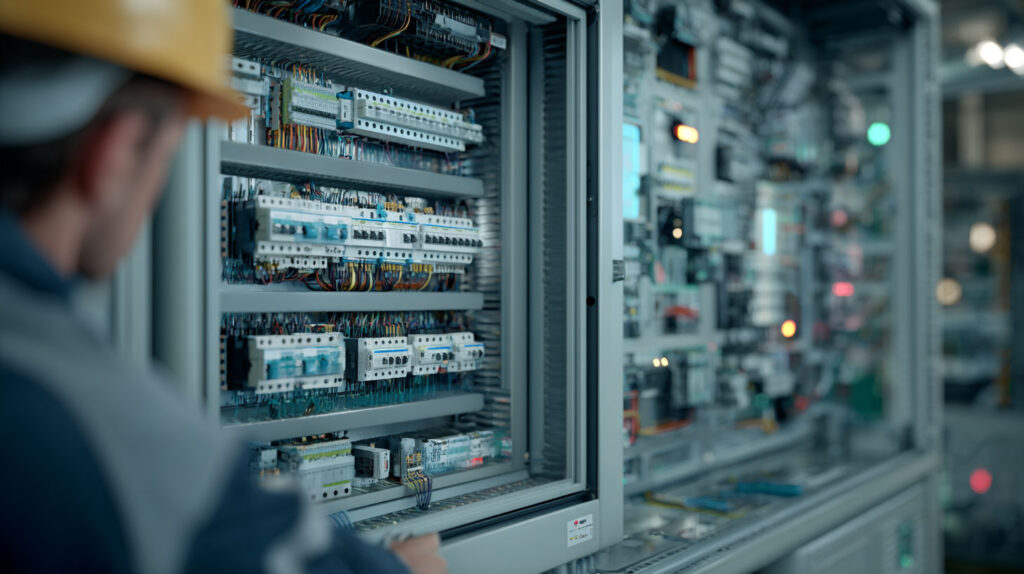

Open-frame internal power supplies are widely used in industrial equipment because they offer flexibility, scalability, and cost efficiency for systems that integrate power directly into an enclosure. Unlike external adapters, open-frame PSUs are designed to be mounted inside industrial housings, allowing OEMs to optimize layout, airflow, and system-level thermal management.

Industrial equipment often operates in controlled enclosures where airflow paths, grounding, and safety barriers are engineered as part of the overall system. Open-frame power supplies take advantage of this environment by eliminating redundant housings and connectors, reducing material cost while improving integration flexibility. This makes them well suited for automation systems, industrial controls, test equipment, and factory machinery.

Another key reason for adoption is power scalability. Open-frame designs are available across a wide range of wattages and form factors, allowing OEMs to standardize internal architectures while supporting different product variants. When selected correctly, they simplify compliance planning and long-term manufacturing continuity.

Top Benefits

• Enables flexible integration within industrial enclosures

• Reduces cost and size compared to enclosed or external supplies

• Supports scalable power architectures across product lines

Best Practices

• Confirm enclosure design supports safe mounting and airflow

• Align power rating with sustained industrial duty cycles

• Evaluate grounding and isolation as part of system design

Helpful Tips

• Avoid assuming bench-test airflow reflects enclosure conditions

• Plan mounting orientation early to support cooling

• Coordinate PSU placement with other heat-generating components

Mini Q&A

Why do industrial OEMs prefer open-frame PSUs?

Because they integrate efficiently into engineered enclosures.

Are open-frame supplies safe for industrial use?

Yes, when proper enclosure and safety design are applied.

Do open-frame PSUs reduce system cost?

Often yes, by removing redundant housings and connectors.

Understanding why open-frame supplies are used helps OEMs choose the right internal power strategy.

(Suggested Links: Internal Power Supplies | Industrial Power Supplies)

How Do Power Rating and Duty Cycle Affect Open-Frame PSU Selection?

Power rating and duty cycle are critical factors when selecting open-frame internal power supplies for industrial equipment. Industrial systems often operate continuously or under heavy load for extended periods. Selecting a PSU based solely on peak power can lead to overheating, derating, or reduced lifespan when exposed to real operating conditions.

Open-frame power supplies are typically specified with derating curves that show how output power changes with temperature and airflow. OEMs must account for ambient conditions inside the enclosure, not just room temperature. A PSU that appears sufficient on paper may struggle when mounted near other heat sources or in high-temperature environments.

Duty cycle also influences component aging. Continuous operation accelerates thermal stress on capacitors, magnetics, and semiconductors. Designing with margin ensures stable operation over time and reduces field failures in long-running industrial applications.

Top Benefits

• Improves reliability under continuous industrial operation

• Reduces thermal stress and premature component aging

• Supports predictable long-term performance

Best Practices

• Size PSUs for continuous load, not peak demand

• Review derating curves at worst-case ambient temperatures

• Build margin for aging and load growth

Helpful Tips

• Avoid running open-frame PSUs near maximum ratings

• Validate power behavior inside final enclosures

• Reassess power needs when adding features or variants

Mini Q&A

Why is duty cycle critical for industrial PSUs?

Because industrial equipment often runs continuously.

Can peak-rated PSUs fail under continuous load?

Yes, thermal stress accumulates over time.

Is oversizing wasteful?

No, it improves reliability and lifespan.

Accounting for duty cycle early prevents reliability issues later.

(Suggested Links: Internal Power Supplies | Power Supply)

What Thermal and Airflow Considerations Matter Most for Open-Frame Designs?

Thermal and airflow considerations are among the most important factors in open-frame internal power supply selection. Because these PSUs lack protective enclosures, they rely heavily on system-level airflow and heat dissipation strategies. Poor airflow planning can quickly negate the benefits of open-frame designs.

Industrial enclosures often contain multiple heat sources, including motors, drives, processors, and relays. Open-frame PSUs placed near these components experience elevated ambient temperatures that reduce available output power. Airflow direction, mounting orientation, and spacing all influence thermal performance.

OEMs must evaluate thermal behavior at the system level. This includes validating airflow paths, avoiding recirculation, and ensuring that PSU components are not shielded from cooling. Early thermal validation reduces the risk of derating or shutdown in the field.

Top Benefits

• Improves thermal predictability inside industrial enclosures

• Reduces derating and overheating risk

• Supports stable operation under variable conditions

Best Practices

• Validate airflow direction and volume in final enclosures

• Avoid blocking PSU ventilation paths

• Separate PSUs from major heat sources where possible

Helpful Tips

• Use thermal imaging during enclosure testing

• Account for dust and airflow degradation over time

• Revalidate cooling when enclosure designs change

Mini Q&A

Do open-frame PSUs require forced airflow?

Often yes, depending on power level and environment.

Can enclosure layout affect PSU output?

Yes, thermal conditions directly impact derating.

Should thermal testing be done early?

Absolutely, before layouts are finalized.

Designing for proper airflow is essential to successful open-frame PSU integration.

(Suggested Links: Open-Frame Power Supplies | Industrial Power Supplies)

CLIENT'S QUOTE

Phihong's Power-Over-Ethernet solutions have transformed our network, boosting efficiency and reducing costs. Their seamless integration has simplified both installation and maintenance.

How Safety, Isolation, and Grounding Requirements Shape Open-Frame PSU Design

Safety, isolation, and grounding requirements strongly shape how open-frame internal power supplies must be selected and integrated in industrial equipment. Unlike external adapters or enclosed supplies, open-frame PSUs rely on the system enclosure to provide protection against electric shock, fire, and environmental exposure. This makes system-level safety design inseparable from power supply choice.

Industrial equipment must meet regional safety standards that define creepage, clearance, leakage current, and protective earthing requirements. Open-frame PSUs are typically certified as components rather than finished products, meaning OEMs are responsible for ensuring the final system meets safety compliance. Improper grounding or insufficient isolation can result in failed certifications or unsafe operating conditions.

OEMs must also consider grounding strategy early. Poor grounding can introduce noise, EMI issues, or safety hazards. Designing a clear protective earth path and understanding how the PSU interfaces with system ground helps avoid compliance failures and field issues.

Top Benefits

• Improves system-level safety and compliance outcomes

• Reduces certification and audit risk

• Supports reliable grounding and noise control

Best Practices

• Verify applicable safety standards for target industrial markets

• Design protective earth and grounding paths intentionally

• Validate creepage and clearance at the system level

Helpful Tips

• Avoid assuming PSU certification covers full system safety

• Review grounding schemes with compliance engineers

• Document safety assumptions tied to PSU integration

Mini Q&A

Are open-frame PSUs certified as finished products?

No, they are usually component-certified and rely on system design.

Does grounding affect EMI and safety?

Yes, grounding impacts both noise and protection.

Should safety be validated early?

Yes, early validation prevents late redesigns.

Integrating safety considerations early ensures open-frame PSUs meet industrial requirements.

(Suggested Links: Internal Power Supplies | Industrial Power Supplies)

Why EMI, Noise, and System Integration Matter More Than PSU Specs Alone

EMI and noise behavior often matter more than datasheet specifications when integrating open-frame internal power supplies into industrial equipment. While datasheets define conducted and radiated emissions under test conditions, real systems introduce cabling, loads, grounding paths, and enclosure effects that can significantly alter EMI performance.

Open-frame PSUs are particularly sensitive to integration details. Cable routing, proximity to switching devices, and enclosure bonding can either suppress or amplify noise. A PSU that passes bench testing may fail system-level EMI testing if integration is not carefully planned.

OEMs should evaluate EMI as a system characteristic rather than a PSU attribute. Early integration testing and thoughtful layout decisions reduce the risk of late-stage compliance failures and rework.

Top Benefits

• Reduces EMI-related certification failures

• Improves system stability and signal integrity

• Shortens time to compliance approval

Best Practices

• Treat EMI testing as a system-level activity

• Plan cable routing and grounding to minimize noise

• Validate EMI behavior inside final enclosures

Helpful Tips

• Keep high-frequency loops short and controlled

• Separate power and signal paths where possible

• Re-test EMI after layout or enclosure changes

Mini Q&A

Can EMI issues appear even with compliant PSUs?

Yes, integration often changes emission behavior.

Does enclosure design affect EMI?

Yes, bonding and shielding influence noise levels.

Is early EMI testing valuable?

Yes, it reduces late-stage surprises.

Managing EMI through integration planning is critical for open-frame PSU success.

(Suggested Links: Power Supply | Internal Power Supplies)

How Manufacturing, Serviceability, and Lifecycle Planning Influence PSU Choice

Manufacturing, serviceability, and lifecycle planning influence open-frame PSU selection as much as electrical performance. Industrial OEMs must consider how power supplies will be assembled, tested, serviced, and supported over many years. Open-frame PSUs that complicate assembly or service increase long-term cost.

Serviceability is especially important for industrial equipment deployed in the field. Power supplies may need inspection or replacement during maintenance cycles. Designs that bury PSUs behind non-serviceable assemblies increase downtime and labor cost.

Lifecycle planning also affects selection. Industrial equipment often remains in production and service for long periods, making availability, documentation continuity, and controlled revision support critical. Choosing open-frame PSUs with stable lifecycles reduces future redesign and service disruption.

Top Benefits

• Improves manufacturability and production efficiency

• Reduces downtime and service cost

• Supports long-term product support

Best Practices

• Evaluate PSU mounting and access during design

• Align PSU choice with expected service intervals

• Confirm long-term availability and documentation support

Helpful Tips

• Avoid PSU placement that requires full disassembly

• Standardize PSU platforms across product families

• Plan spare and replacement strategies early

Mini Q&A

Do open-frame PSUs affect assembly flow?

Yes, mounting and wiring influence production efficiency.

Is service access important for industrial equipment?

Yes, it directly impacts downtime and cost.

Should lifecycle planning influence PSU selection?

Absolutely, long-term availability matters.

Considering manufacturing and service needs early ensures open-frame PSUs remain viable long term.

(Suggested Links: Industrial Power Supplies | Internal Power Supplies)

How Phihong Supports OEMs Selecting Open-Frame Internal Power Supplies for Industrial Equipment

Selecting the right open-frame internal power supply requires more than matching voltage and wattage. Phihong supports OEMs by approaching internal PSU selection as a system-level industrial design decision that considers enclosure conditions, thermal behavior, safety compliance, EMI performance, and long-term manufacturability.

Phihong evaluates open-frame power supplies under sustained industrial duty cycles and enclosure-constrained airflow scenarios. Designs emphasize predictable derating behavior, stable grounding interfaces, and compliance readiness when integrated into complex industrial systems. This reduces late-stage redesigns and certification delays that commonly occur when PSU selection is treated as an isolated component decision.

As a long-term manufacturing partner, Phihong also provides lifecycle stability, documentation continuity, and global compliance support. This enables OEMs to deploy industrial equipment with internal power architectures that scale reliably from pilot builds through long-term production and field service.

(Suggested Links: Internal Power Supplies | Industrial Power Supplies)

FEATURED RESOURCE

Phihong's Power-Over-Ethernet solutions have transformed our network, boosting efficiency and reducing costs.

FAQ

What makes open-frame internal power supplies suitable for industrial equipment?

Open-frame internal power supplies are suitable for industrial equipment because they integrate directly into engineered enclosures that provide protection, grounding, and airflow control. This allows OEMs to optimize system-level thermal management and reduce cost compared to enclosed or external solutions.

When properly integrated, open-frame PSUs offer flexibility, scalability, and long-term reliability in industrial environments.

Do open-frame PSUs require special safety considerations?

Yes. Open-frame PSUs are typically component-certified and rely on the final system design to meet safety requirements. OEMs must ensure proper enclosure protection, grounding, creepage, and clearance distances.

Early coordination with compliance teams helps prevent certification issues later in development.

How does airflow affect open-frame PSU performance?

Airflow directly affects available output power and temperature rise. Poor airflow or recirculation inside industrial enclosures can cause derating or thermal shutdown.

Validating airflow paths and PSU orientation inside final enclosures is critical for reliable operation.

Can EMI issues arise even if the PSU meets datasheet limits?

Yes. EMI performance depends heavily on system integration, including cable routing, grounding, and enclosure bonding. A compliant PSU can still fail system-level EMI testing if integration is not planned carefully.

System-level EMI validation reduces late-stage rework.

How should OEMs plan for long-term support when using open-frame PSUs?

OEMs should confirm long-term availability, documentation continuity, and controlled revision processes. Industrial equipment often has long service lifetimes, making lifecycle support as important as initial performance.

Selecting PSUs with stable lifecycles reduces future redesign and service disruption.