BLOG

Best OEM Guide to AC/DC Power Adapters: Compliance, Efficiency Standards, and Critical Design Considerations

QUICK LINKS

What key specifications should OEMs evaluate when selecting an AC/DC power adapter?

For OEMs designing products for global distribution, AC/DC adapter selection is far more than matching voltage and current. A power adapter directly influences product safety, thermal behavior, electromagnetic performance, global compliance, and long-term reliability. Yet many engineering teams overlook critical datasheet specifications such as ripple voltage, hold-up time, inrush current, transient response, temperature derating, and global certification marks. These parameters determine how well a power supply performs under real-world stress, not just on the bench.

OEM products vary widely—battery chargers, IoT devices, robotics, sensors, medical devices, POS systems, and industrial controllers—and each category has very different power stability and noise requirements. A poor adapter choice can lead to unexpected resets, EMI failures, shortened component life, product delays, and expensive recalls. Evaluating AC/DC adapters properly prevents these issues and ensures the power subsystem aligns with product design goals, environmental requirements, and global regulatory expectations.

Top Benefits

-

Ensures reliable system performance across variable load conditions

-

Improves product safety and global regulatory approval success

-

Reduces field failure rates and long-term warranty costs

Best Practices

-

Review ripple, hold-up, inrush, and load regulation values together

-

Confirm UL/CE/UKCA/PSE/RCM/CCC marks for global markets

-

Validate adapter behavior inside the actual device enclosure

Understanding these core specifications allows OEMs to select adapters that support stable operation, minimize compliance risk, and maintain reliability throughout the product lifecycle.

(Suggested Links: Internal Power Supply Guide | USB Power Delivery)

FEATURED PRODUCTS

AA03A-075A-R

- Output Power - 2.75W

- Output Volt - 7.5V

- Output Current - 0.366A

- Features - Fixed Blade AC Input, Limited Power Source, Class B EMI, Level VI Efficiency, Standard Barrel Connector

AC Series

- Output Current - 16A

- Features - Mode 2-chargers can use a circuit ranging from 8Amp to 16Amp with a local standard AC input plug installed for operation, Provides overcurrent, over voltage and short circuit protection, Protected against strong jets of water from all directions, Continuously monitors/supervises the ground connection between the AC supply and EV to ensure safe and reliable charging

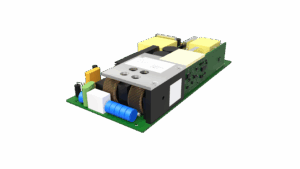

BF550-234A-R

- Output Power - 550W

- Output Volt - 12Vdc / 54.5Vdc

- Features - Universal AC Input range, Class I Design , Class B EMI , High Efficiency Performance , OVP, OCP, SCP, OTP Protections , Operating Altitude: 5,000M

DA1000Z-240AEV-R

- Output Power - 1000W

- Output Volt - 24V

- Output Current - 1000W

- Features - Extended operating temperature range of -40℃ to 70℃, Fan-less aluminum case filled with heat conductive glue, Able to withstand 10G vibration, Power on LED indicator, Short Circuit, Over Current, Over Voltage, and Over Temperature Protections, & Adjustable output through potentiomete

DA60U-240A-R

- Output Power - 60W

- Output Volt - 24V

- Output Current - 2.5A

- # of ports - 1

- Features - RESNA Compliant, CEC Compliant, LED Indicators Charge State, OVP, OTP, SCP, Charges AGM Batteries, Max 12hrs Charging Time

DA200U-250A-R

- Output Power - 200W

- Output Volt - 24V

- Output Current - 8A

- # of ports - 1

- Features - RESNA Compliant, CEC Compliant, LED Indicators Charge State, OVP, OTP, SCP, Dual-Mode Charger, Charges GEL or AGM batteries, Max 12hrs Charging Time

Why do global efficiency standards like DOE Level VI and CoC Tier 2 matter for OEM power adapter selection?

Energy efficiency regulations shape nearly every external power supply sold today. The U.S. Department of Energy’s DOE Level VI and the European CoC Tier 2 requirements govern standby power, active-mode efficiency, and multi-point load testing. For OEMs, these standards determine whether a product is legally allowed to enter major markets. Non-compliant adapters can fail customs, be rejected by distributors, or trigger expensive redesigns late in development.

High efficiency also enhances product stability. Efficient adapters generate less heat, which improves component lifespan, reduces EMI spikes, and prevents thermal shutdowns—especially in sealed or compact enclosures. Efficiency impacts long-term reliability for IoT devices, networking equipment, consumer electronics, medical devices, and robotics systems expected to operate continuously. OEMs who treat efficiency as a core design requirement avoid many of the long-term reliability challenges caused by thermal stress and energy waste.

Top Benefits

-

Ensures global market access in the U.S. and EU

-

Supports thermal management and stable long-term performance

-

Reduces product energy consumption and total cost of ownership

Best Practices

-

Request full efficiency test reports for 25%, 50%, 75%, and 100% load

-

Confirm no-load power meets DOE/CoC thresholds

-

Validate thermal rise at max load in your final enclosure

Efficiency regulations protect the OEM’s product roadmap by ensuring adapter stability, global compliance, and long-term durability across varied environments.

(Suggested Links: Open-Frame Power Supplies | Medical Power Supplies)

How do ripple voltage, hold-up time, and inrush current affect OEM device performance?

Ripple, hold-up time, and inrush current are three of the most influential—and misunderstood—parameters in AC/DC adapter datasheets. Ripple affects the “cleanliness” of the output power. Excess ripple causes noise issues, inaccurate sensor readings, audio artifacts, unstable RF systems, and early capacitor aging. OEMs building medical, RF, or digital-precision systems must choose adapters with strong filtering and low noise output.

Hold-up time measures how long a power supply maintains output during an input dropout. A short hold-up time causes resets, data corruption, and unexpected shutdowns in devices deployed in regions with unstable power grids. Inrush current describes the surge of power when the adapter first turns on. High inrush can trip circuit breakers, stress components, or cause intermittent boot-up failures. Selecting adapters with proper surge limiting and predictable startup behavior is essential in multi-device systems, industrial lines, and IoT deployments.

Top Benefits

-

Reduces device resets, noise interference, and boot failures

-

Ensures stable operation during real-world voltage dips

-

Protects sensitive electronics from high-surge startup stress

Best Practices

-

Validate ripple and EMI under dynamic load, not just static load

-

Confirm hold-up values at minimum input voltage

-

Test inrush under low-temperature and high-voltage conditions

Evaluating ripple, hold-up, and inrush as a combined behavior profile helps OEMs prevent hidden reliability issues, customer complaints, and unexpected certification failures.

(Suggested Links: Innovations in Medical Power Design | Battery Chargers)

CLIENT'S QUOTE

Phihong's Power-Over-Ethernet solutions have transformed our network, boosting efficiency and reducing costs. Their seamless integration has simplified both installation and maintenance.

Environmental performance and derating curves determine real-world reliability

An AC/DC adapter might perform flawlessly in a controlled lab, yet fail prematurely when exposed to real-world temperatures, humidity levels, airflow restrictions, or altitude conditions. For OEMs deploying products globally, environmental specifications are just as important as electrical ones. These include operating temperature ranges, storage temperature, humidity tolerance, altitude limits, vibration resistance, and especially derating curves—graphs that show how output power decreases as temperature rises.

Ignoring these values can lead to unexpected field failures. For example, a 12V adapter rated at full power up to 40°C may derate significantly at 50°C, which is common inside sealed enclosures. Similarly, high humidity or poor airflow environments—like kiosks, medical carts, and industrial control panels—can stress components beyond their intended limits. Derating curves help OEMs understand exactly how the adapter behaves in harsh thermal environments and whether additional cooling, ventilation, or enclosure redesign is needed.

Top Benefits

-

Prevents premature failures due to heat, humidity, or altitude

-

Improves long-term performance under global deployment conditions

-

Reduces warranty claims and customer downtime

Best Practices

-

Review derating curves early during enclosure design

-

Test adapters inside actual housings, not just open-air conditions

-

Ensure adequate ventilation or thermal mitigation strategies

Environmental ratings and derating curves empower OEMs to design products that remain reliable in every temperature zone and installation scenario worldwide.

(Suggested Links: Open-Frame Power Supplies | PoE Injectors)

Compliance and safety approvals protect OEM devices and streamline certification

Safety approvals such as UL, CE, GS, CCC, PSE, UKCA, and RCM are more than labels—they determine whether OEM products can be legally sold in global markets. AC/DC adapters must meet electrical, fire, insulation, and EMC requirements specific to each region. Medical-grade adapters must comply with IEC 60601-1, while industrial solutions may require IEC 62368-1 or 61010-1 depending on the application. A non-certified adapter can delay product launches, fail regulatory audits, or result in costly re-engineering.

OEMs often underestimate how deeply power supply certification impacts their end device approval. Regulatory bodies expect full traceability of the adapter’s certifications, reports, and manufacturing consistency. Suppliers who maintain strong documentation and undergo routine factory audits provide OEMs with predictable compliance pathways. Choosing a reputable partner reduces risk, accelerates approval timelines, and ensures consistent performance across production runs.

Top Benefits

-

Ensures legality and smooth global market entry

-

Reduces regulatory delays and certification failures

-

Protects both product integrity and end-user safety

Best Practices

-

Confirm certification marks directly against official databases

-

Require full test reports and CB Scheme documentation

-

Choose suppliers with longstanding regulatory track records

Compliance is not optional; selecting properly approved adapters ensures safe, legal, and efficient expansion into international markets.

(Suggested Links: Medical Power Supplies | Internal Power Supply Guide)

Interchangeable plug systems simplify manufacturing, logistics, and global distribution

Interchangeable plug systems allow OEMs to use a single power adapter body for multiple regions by swapping only the plug head. This dramatically streamlines manufacturing, reduces SKU counts, simplifies packaging, and minimizes forecasting errors. By separating the adapter’s electrical core from its plug geometry, OEMs avoid building separate power supplies for each market, avoiding warehouse clutter and excess inventory.

From a logistics standpoint, interchangeable plug systems enable universal product packaging. OEMs can ship the same device to multiple countries and simply bundle the correct plug type for U.S., EU, UK, AU, KR, or JP markets. This flexibility reduces shipping costs, improves pallet density, and prevents returns caused by plug mismatches. Engineering teams also benefit because the core adapter body can be certified once, with only the plug heads requiring regional approvals.

Top Benefits

-

Reduces SKUs and lowers warehousing costs

-

Simplifies global forecasting and distribution workflows

-

Accelerates compliance and global market entry

Best Practices

-

Verify plug heads carry proper regional certifications

-

Store plug kits separately for flexible fulfillment

-

Use scalable packaging systems designed for multi-region deployment

Interchangeable plug architectures give OEMs a more agile supply chain, reduce risk, and support faster global expansion with minimal overhead.

(Suggested Links: USB Power Delivery | Battery Chargers)

How Phihong supports OEMs with compliant, efficient, and globally deployable AC/DC power solutions

Phihong provides OEMs with a comprehensive portfolio of AC/DC power adapters engineered to meet the highest standards in safety, efficiency, and global compliance. Whether an OEM requires DOE Level VI, CoC Tier 2, UL/CE/UKCA, medical-grade IEC 60601-1, or industrial IEC 62368-1 approvals, Phihong’s product family offers pre-certified solutions that reduce development time and eliminate costly regulatory hurdles. Their adapters are designed with low ripple, strong transient response, reliable hold-up time, and controlled inrush current—ensuring stable performance across sensitive electronics, IoT devices, industrial controllers, robotics, and medical systems.

Phihong’s engineering support extends beyond hardware. OEMs benefit from detailed datasheets, compliance documentation, application insights, and long-term product availability—a critical factor for global product lines with multi-year lifecycles. Their worldwide production capabilities ensure consistent quality, while their modular plug systems simplify distribution into multi-region supply chains. From early-stage design consultation to mass production and field deployment, Phihong gives OEMs the tools, guidance, and reliability required to build safe, compliant, future-ready devices.

(Suggested Links: Internal Power Supply Guide | Contact Phihong)

FEATURED RESOURCE

Phihong's Power-Over-Ethernet solutions have transformed our network, boosting efficiency and reducing costs.

FAQ

What are the most important AC/DC adapter specifications OEMs should evaluate during product development?

OEMs must evaluate several core specifications when selecting an AC/DC adapter: ripple voltage, hold-up time, inrush current, load regulation, efficiency, power factor, and protection features such as over-current, over-temperature, and short-circuit safeguards. Ripple determines noise performance, hold-up time dictates stability during low-line dips, and inrush current affects startup safety and breaker compatibility. Environmental specifications—temperature range, humidity tolerance, and derating curves—ensure reliability across global deployments.

OEMs should also confirm all relevant safety and efficiency approvals. Products intended for the U.S. require DOE Level VI and UL certification. European-bound products must meet CoC Tier 2, CE, and EMC requirements. Applications in medical, industrial, or networking markets require additional IEC-specific approvals. Failure to match the correct certifications to the correct product category can delay market entry or cause a device to fail final compliance testing.

Evaluating these specifications holistically ensures the adapter supports long-term product reliability, reduces warranty incidents, and maintains stable performance in demanding real-world environments. Proper power supply selection protects both the product and the OEM brand.

How do ripple voltage and hold-up time affect sensitive OEM electronics?

Ripple voltage directly impacts noise-sensitive circuits such as sensors, amplifiers, microcontrollers, and RF systems. Excess ripple creates interference that may cause inaccurate readings, communication failures, audio noise, or unstable digital operation. OEMs designing medical equipment, communication systems, or precision electronics must prioritize adapters with low ripple and strong internal filtering. Ripple that exceeds a device’s tolerance often results in intermittent field failures that are difficult and costly to diagnose.

Hold-up time affects how long a device stays operational during input power interruptions or brownouts. A short hold-up time can cause resets, corrupted data, and unexpected shutdowns—especially in products deployed where grid stability is poor. Devices with internal processors or time-sensitive operations often require longer hold-up values to provide enough ride-through time to finish critical tasks.

Together, ripple and hold-up time define electrical stability. OEMs that review these specifications proactively avoid noise-related field failures, prevent intermittent resets, and ensure consistent device performance across global environments—whether the product is used indoors, outdoors, or in medically sensitive conditions.

Why do efficiency standards like DOE Level VI and CoC Tier 2 matter beyond regulatory compliance?

Efficiency standards shape product reliability, thermal performance, and long-term operational cost. DOE Level VI and CoC Tier 2 impose strict requirements on standby power consumption and multi-load active efficiency. Adapters meeting these standards generate less waste heat, which reduces thermal stress on components, improves MTBF, and increases product lifespan—critical for devices that operate continuously.

Low-efficiency adapters run hotter, degrade faster, and create more EMI—leading to unpredictable behavior in sensitive electronics. Heat is one of the largest contributors to premature power supply failure, and inefficient adapters accelerate this process. OEMs deploying devices in sealed enclosures, outdoor kiosks, or networking closets benefit significantly from using highly efficient supplies.

These standards also support sustainability goals. Businesses increasingly require energy-efficient components to meet environmental regulations, reduce operational expenses, and improve corporate responsibility profiles. For OEMs, selecting efficient adapters is no longer just a compliance task—it is part of designing reliable, competitive, long-lasting products.

How do safety approvals like UL, CE, PSE, and IEC standards protect OEMs during global certification?

Safety approvals ensure that AC/DC adapters meet regional electrical, fire, insulation, and EMC requirements. Using adapters that lack the appropriate approvals can immediately stall global distribution. UL is required in the U.S., CE in the EU, PSE in Japan, CCC in China, and RCM in Australia/New Zealand. Additional IEC standards govern specific markets, such as IEC 60601-1 for medical systems and IEC 62368-1 for ICT and industrial applications.

OEMs that fail to use a properly certified power supply risk regulatory rejection, factory audits, legal disputes, or forced product recalls. Certification also impacts insurance coverage—products powered by non-certified adapters may not be legally protected against liability claims. Beyond safety and legality, certified adapters produce more consistent, predictable performance.

By ensuring full certification from the start of product development, OEMs reduce compliance risks, accelerate approvals, and prevent delays during customs inspections, distributor reviews, and retail onboarding.

Why should OEMs choose Phihong as a long-term partner for AC/DC power adapter solutions?

Phihong provides OEMs with globally certified, high-reliability AC/DC adapters that meet DOE Level VI, CoC Tier 2, UL, CE, PSE, CCC, and other regional standards. Their products are engineered for low ripple, stable regulation, controlled inrush current, and long-term thermal performance—qualities essential for reliable OEM device operation.

With decades of engineering expertise, Phihong supports OEMs through every stage of development: design review, compliance guidance, prototype testing, documentation, and mass production. Their interchangeable plug systems simplify logistics for global distribution, while their extensive product catalog offers solutions for consumer electronics, industrial automation, IoT, robotics, and medical device applications.

OEMs trust Phihong because they deliver consistency, certified performance, and technical clarity—reducing risk, avoiding re-engineering cycles, and ensuring market readiness for products sold worldwide.