BLOG

Custom Power Supplies: How to Reduce OEM Time‑to‑Market with Custom Power Supply Manufacturing

Table of contents

How Can Custom Power Supplies Accelerate OEM Product Development?

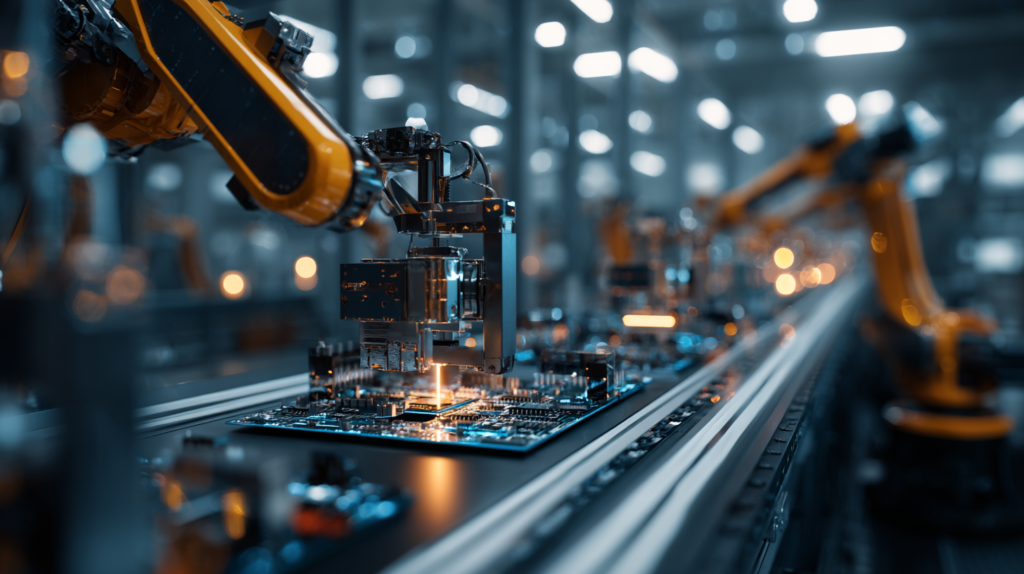

Speed-to-market is a competitive advantage for today’s OEMs. Whether you’re developing a next-gen EV charger, a medical-grade device, or industrial automation equipment, long development timelines can erode profitability. A major contributor to slowdowns? Poorly matched or inflexible power supply solutions.

Custom power supply manufacturing removes those bottlenecks by aligning your electrical, mechanical, and regulatory needs early in the process. Instead of retrofitting a generic PSU, OEMs gain a partner who co-engineers a power solution optimized for every phase—from prototype to production.

Top Features

- Early Stage Co-Design: Custom manufacturers collaborate during initial system design to integrate requirements and reduce revisions later.

- Application-Specific Builds: Power solutions are purpose-built for voltage, current, thermal constraints, and housing dimensions.

- Rapid Prototyping: In-house prototyping tools speed up development, testing, and pre-certification.

Top Benefits

- Eliminates delays caused by integration issues

- Reduces risk of design rework or compliance failures

- Aligns power development timeline with overall product goals

Best Practices

- Involve your power supply partner during concept development

- Share mechanical drawings and thermal specs up front

- Ask for pre-certification and compliance consultation during design

A custom power supply speeds up development not by working harder—but by working smarter and in parallel with your product roadmap.

What Should You Look for in a Custom Power Supply Manufacturer?

Not all power supply partners are created equal. While many can build to spec, few have the technical depth and project agility OEMs need to hit tight launch windows. The best partners bring engineering insights, production foresight, and regulatory experience to the table—acting as an extension of your product team, not just a vendor.

Choosing a partner with proven experience in your industry and end-use application is critical. This ensures they can anticipate design challenges and help future-proof your product as standards and specs evolve.

Top Features

- Cross-Sector Engineering Experience: Insight into telecom, medical, EV, and industrial requirements

- Full-Service Design + Compliance Teams: In-house teams that handle thermal, EMI, safety, and certification logistics

- Supply Chain + Production Capabilities: Access to scalable, global manufacturing resources

Top Benefits

- Improved first-pass design success

- Fewer delays related to testing or regulatory errors

- Scalable solutions that grow with your product line

Best Practices

- Review case studies or client references before signing

- Ask about multi-region compliance history (e.g., UL, CE, IEC)

- Evaluate how fast they can adapt to design changes or shortages

A qualified partner accelerates your process not by rushing—but by removing friction from every step of development.

Reducing Time-to-Market with Built-for-Integration Power Supplies

Off-the-shelf PSUs often require extra engineering to fit within your final product. That time spent modifying PCB layouts, reworking thermal paths, or sourcing adapters can push your project off schedule. With custom solutions, integration is built into the design from day one—eliminating much of that wasted time.

Built-for-integration power supplies match your mechanical and system-level design, ensuring a smoother path to production, better reliability, and minimal last-minute surprises.

Top Features

- Optimized Mechanical Fit: Supplies are designed to fit seamlessly into your housing or enclosure.

- Thermal and EMI Considerations Baked In: No need to redesign later to solve overheating or interference problems.

- Flexible Output and Connector Configurations: Tailored to match your interface and power needs exactly.

Top Benefits

- Less time spent reworking internal layouts

- Reduced risk of EMI-related delays in certification

- Faster ramp-up during pilot production

Best Practices

- Share enclosure CAD files with your supplier early

- Align on EMI/thermal priorities before prototyping

- Validate with full-system mockups, not just electrical tests

When power supplies are designed for your product—not just for the shelf—everything moves faster.

CLIENT'S QUOTE

"Phihong’s PoE solutions have made a huge difference for us! Our network runs more efficiently, and we’ve seen real cost savings. We couldn’t be happier!"

How Custom Power Supply Design Minimizes Compliance Delays

Regulatory certifications are critical—but often unpredictable. A single failed EMI or thermal test can derail your launch by weeks. With custom power supply design, these issues are proactively addressed during development, not discovered during testing.

By building compliance considerations into the earliest stages of design, custom manufacturers help OEMs avoid rework, reduce third-party testing rounds, and accelerate certification.

Top Features

- Pre-Compliance Engineering: Designs are built to meet industry-specific standards from day one.

- In-House Testing Capabilities: Some partners offer their own EMI, thermal, and safety testing to catch issues early.

- Global Standards Knowledge: Familiarity with UL, CE, IEC 60601, and other regulatory frameworks ensures alignment across markets.

Top Benefits

- Faster certification and approvals

- Fewer unexpected design changes during lab testing

- More predictable project timelines

Best Practices

- Define compliance goals in your RFP

- Ask your partner about past success with specific standards

- Validate EMI and safety with pre-compliance tools during prototyping

Engineering for compliance from the start transforms testing from a risk into a formality.

Custom BOM and Supply Chain Planning for Faster Production

Sourcing power components from multiple vendors often leads to delays, substitutions, and version mismatches. Custom power supply manufacturing simplifies this by consolidating your BOM and aligning it with your supplier’s sourcing and production strategy.

A tailored BOM ensures that each part is spec’d, stocked, and scaled to support your launch schedule—eliminating the scrambling that often happens when off-the-shelf components go EOL or experience shortages.

Top Features

- Custom BOM Consolidation: Combines essential functions into one SKU

- Sourcing Around Preferred Vendors: Uses your approved components where possible

- Forecast and Inventory Coordination: Ensures on-hand stock matches production schedules

Top Benefits

- Avoids supply chain bottlenecks

- Streamlines procurement and inventory management

- Reduces risk of last-minute part changes

Best Practices

- Share long-term production volume forecasts with your power partner

- Align component preferences and sourcing policies early

- Build alternate sourcing plans into your BOM strategy

Smart BOM planning is one of the easiest ways to remove obstacles from your manufacturing schedule.

How Custom Manufacturing Supports Future Product Versions

Many OEMs release multiple versions of a product across different markets or upgrade their systems over time. A good custom power solution isn’t static—it’s designed with flexibility in mind. Modular or scalable power platforms allow for quick adaptation without starting from scratch.

Custom manufacturers often provide ongoing engineering support so you can adjust voltage, current, or mechanical specs as your product line evolves.

Top Features

- Modular Architecture: A shared design platform that supports multiple SKUs

- Engineering Continuity: Retains your documentation and tooling for future revisions

- Future-Proof Layouts: Designed with headroom for evolving power demands

Top Benefits

- Faster rollout of product updates

- Lower cost of developing future variations

- Greater consistency across your product family

Best Practices

- Choose a partner who offers multi-year engineering support

- Ask about future update timelines and cost estimates

- Build flexibility into your initial design scope

Custom solutions don’t just support your current launch—they enable future success at scale.

How Phihong USA Helps OEMs Accelerate Time-to-Market

Phihong USA specializes in custom power supply manufacturing tailored for OEMs in fast-moving industries. Whether you’re launching a new product or updating an existing line, our team brings deep technical expertise, scalable manufacturing, and global supply chain coordination to every project.

From concept to certification, Phihong engineers help you avoid delays by integrating early, engineering for compliance, and building solutions around your specific goals. With decades of experience across telecom, EV, medical, and industrial sectors, we understand what it takes to move quickly—without compromising quality or safety.

We offer:

- Rapid design and prototyping for custom AC-DC and DC-DC power supplies

- In-house testing and pre-certification support

- Full production and global logistics support

- Long-term scalability for evolving product roadmaps

Ready to move faster? Contact Phihong today for a free consultation and discover how our custom power supply solutions can keep your next launch ahead of schedule.

Visit www.phihong.com or email our sales team at usasales@phihongusa.com to get started.

Contact Our Team Today!

Our dedicated sales team and international partners are prepared to support you with your latest projects and initiatives globally.

Explore More with Phihong USA

As we conclude our exploration of PoE technology, it’s evident how these innovations are streamlining power and data integration across various industries. Phihong USA stands at the forefront of this technological advancement, offering a diverse range of power solutions designed to meet the evolving needs of modern industries.

Phihong USA’s extensive product lineup includes:

- Power over Ethernet (PoE) Solutions: Delivering reliable power and data transmission over a single cable, ideal for simplifying network installations and reducing costs.

- AC/DC Adapters and Power Supplies: From compact adapters to industrial-grade power supplies, Phihong provides solutions that ensure efficiency and reliability in various applications.

- Battery Chargers: Customizable chargers for lithium-ion and lead-acid batteries, supporting a wide range of power requirements for mobility and industrial applications.

- Medical Power Supplies: Specialized power solutions designed to meet the stringent requirements of the healthcare industry, ensuring safety and reliability.

Phihong USA is committed to innovation and excellence, continually developing products that meet the highest standards of performance and reliability. Their global reach and dedication to customer support make them a trusted partner in powering the future.

Here are some useful links to explore Phihong USA’s offerings further and bring in new potential clients:

Visit Phihong USA to discover how their advanced power solutions can support your business needs. Whether you’re looking to upgrade your network, or find reliable power supplies, Phihong USA has you covered.

By choosing Phihong USA, you’re partnering with a leader in power technology, ensuring your operations run smoothly and efficiently with top-tier power solutions. Contact Us today!

FAQ

What is the main advantage of using a custom power supply over an off-the-shelf unit?

The primary advantage of using a custom power supply is alignment—alignment with your product’s specific electrical, mechanical, and regulatory requirements. Off-the-shelf power supplies may seem like a fast, low-cost solution, but they often introduce hidden delays due to compatibility issues, EMI problems, thermal challenges, or certification mismatches. In contrast, a custom power supply is designed specifically for your application, which leads to faster integration, improved reliability, and a smoother path through compliance testing.

Another major benefit is time. While it may seem counterintuitive, custom solutions often accelerate time-to-market. Why? Because when your PSU is built to fit your product, there’s less need for late-stage rework or component substitutions. Engineering teams can move faster without needing to solve problems that stem from trying to “make something fit” that wasn’t designed for the job.

In industries like EV, telecom, or medical devices—where regulatory scrutiny is high and competition is fierce—those time and performance advantages make a measurable impact. Plus, with many custom manufacturers offering scalable production, you can quickly go from prototype to volume without changing suppliers or redesigning your PSU.

How early should OEMs involve a custom power supply manufacturer in the product development cycle?

Ideally, OEMs should bring in their custom power supply partner during the initial concept phase or system architecture planning stage. Waiting until after the mechanical design is finalized—or worse, after the product has been prototyped—can lead to unnecessary delays and compromises.

Early engagement allows your power partner to contribute critical input on form factor, heat dissipation, mounting requirements, EMI shielding, and more. They can also preemptively address compliance issues related to UL, CE, or IEC standards, which might otherwise derail your timeline if discovered late.

Involving your power supply partner early also creates opportunities to co-develop prototypes, share CAD files, and validate integration. This collaboration saves time downstream and ensures your entire system is designed holistically—not pieced together.

If your launch date is aggressive, loop your PSU manufacturer in right after your requirements doc is finalized. Some OEMs even consult during product ideation, especially if power delivery is a major innovation area (like in high-power robotics or battery-backed devices).

Can custom power supplies help with global compliance requirements?

Absolutely. One of the most valuable benefits of working with a custom power supply manufacturer is gaining access to compliance engineering expertise. Regulations vary significantly between regions and industries. A power supply that works perfectly in the U.S. might fail EMI standards in the EU or fall short of safety protocols for medical or telecom applications.

Custom manufacturers that specialize in global markets understand how to build power solutions that comply with certifications like UL, CE, FCC, CCC, IEC 60601 (medical), IEC 62368 (IT equipment), and more. They bake these compliance goals into the design—reducing delays at the testing stage and increasing the likelihood of first-pass certification.

Moreover, many reputable suppliers conduct pre-compliance testing in-house, simulating real-world performance to ensure thermal stability, electromagnetic compatibility (EMC), and other factors meet required standards. This proactive approach saves time and money.

When your product needs to ship globally—or meet stringent industry requirements—a custom power supply can be the key to unlocking rapid, risk-free expansion into new markets.

What are some risks of using off-the-shelf power supplies for complex OEM devices?

While off-the-shelf (OTS) power supplies offer convenience and lower initial costs, they often carry hidden risks—especially for OEMs developing specialized or high-performance products.

One risk is misalignment with mechanical and thermal requirements. OTS units are not designed for your specific enclosure or heat dissipation environment, which can lead to overheating, poor reliability, or failed compliance tests. Another issue is feature gaps. If the PSU lacks protections or smart controls needed by your application, you’ll need to retrofit external circuits, adding complexity and cost.

Compliance is another major concern. OTS PSUs might be certified, but not in the specific configuration or use case relevant to your industry. If your device fails UL, CE, or FCC testing due to the power supply, you’ll be stuck with costly delays.

Lastly, there’s the problem of supply chain instability. If the manufacturer changes the design or phases out the model, your production is at risk. With a custom PSU, lifecycle and component availability are managed in sync with your product roadmap.

In short: OTS can work for generic applications, but for complex OEM products, they often create more problems than they solve.

How does Phihong USA support fast-moving OEMs with custom power solutions?

Phihong USA supports OEMs by offering a complete, end-to-end custom power supply manufacturing service designed to reduce time-to-market while enhancing product performance and reliability.

We start by embedding our engineering team into your development cycle. Our specialists in thermal design, EMI control, and regulatory compliance work directly with your product designers to co-create a solution that fits perfectly—electrically and mechanically. From rapid prototyping to high-volume manufacturing, our workflow is built around your timeline.

We also offer in-house testing, pre-certification guidance, and support for global compliance standards across telecom, EV, medical, and industrial markets. Our supply chain management ensures component availability and BOM flexibility—even during periods of market volatility.

What sets Phihong apart is our ability to adapt. We support evolving product lines, create forward-compatible designs, and build for global scalability. Whether you’re launching your first product or expanding into international markets, Phihong can help you get there faster—without compromising safety, quality, or performance.

To learn more or start a custom project, visit www.phihong.com or contact us directly at sales@phihongusa.com.