BLOG

How Should OEMs Choose Between Board-Mount and Brick DC/DC Converters for Power System Design?

QUICK LINKS

DC Power Adapters Explained: How High-Efficiency Adapters Upgrade Power Systems

Why does DC/DC converter form factor matter in OEM power system design?

For OEMs designing power systems for industrial control, automation, robotics, networking, or embedded electronics, DC/DC converter form factor is not just a packaging decision. It directly affects thermal performance, scalability, compliance, manufacturability, and long term reliability. Board-mount and brick DC/DC converters are designed for different power levels, system architectures, and deployment environments. Choosing the wrong form factor can lead to inefficient layouts, thermal bottlenecks, or costly redesigns later in the product lifecycle.

Board-mount converters are typically smaller and intended for direct PCB integration. They are commonly used in distributed power architectures where multiple low to medium power rails are required close to the load. Brick converters, by contrast, are higher power modules often used as intermediate bus converters. They are designed to deliver substantial power from a centralized location before downstream regulation occurs. OEMs must consider how power is distributed across the system, how heat is managed, and how serviceability is handled when selecting between these options.

The form factor decision also influences certification strategy and supply chain planning. Brick converters may simplify thermal and compliance challenges at higher power levels, while board-mount solutions often reduce BOM cost and board complexity for lower power applications. Understanding how each form factor aligns with system goals helps OEMs avoid mismatches that compromise performance or scalability.

Top Benefits

-

Aligns power architecture with system size and load distribution

-

Improves thermal management and enclosure design decisions

-

Reduces redesign risk caused by form factor limitations

Best Practices

-

Map power levels and rail distribution early in system design

-

Consider future scalability, not just initial power needs

-

Evaluate thermal and airflow constraints alongside electrical specs

Choosing the correct DC/DC converter form factor ensures that OEM power systems remain efficient, manufacturable, and reliable across real world operating conditions.

FEATURED PRODUCTS

AA03A-075A-R

- Output Power - 2.75W

- Output Volt - 7.5V

- Output Current - 0.366A

- Features - Fixed Blade AC Input, Limited Power Source, Class B EMI, Level VI Efficiency, Standard Barrel Connector

AC Series

- Output Current - 16A

- Features - Mode 2-chargers can use a circuit ranging from 8Amp to 16Amp with a local standard AC input plug installed for operation, Provides overcurrent, over voltage and short circuit protection, Protected against strong jets of water from all directions, Continuously monitors/supervises the ground connection between the AC supply and EV to ensure safe and reliable charging

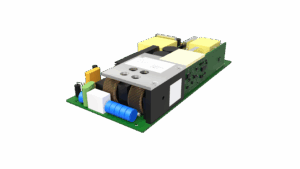

BF550-234A-R

- Output Power - 550W

- Output Volt - 12Vdc / 54.5Vdc

- Features - Universal AC Input range, Class I Design , Class B EMI , High Efficiency Performance , OVP, OCP, SCP, OTP Protections , Operating Altitude: 5,000M

DA1000Z-240AEV-R

- Output Power - 1000W

- Output Volt - 24V

- Output Current - 1000W

- Features - Extended operating temperature range of -40℃ to 70℃, Fan-less aluminum case filled with heat conductive glue, Able to withstand 10G vibration, Power on LED indicator, Short Circuit, Over Current, Over Voltage, and Over Temperature Protections, & Adjustable output through potentiomete

DA60U-240A-R

- Output Power - 60W

- Output Volt - 24V

- Output Current - 2.5A

- # of ports - 1

- Features - RESNA Compliant, CEC Compliant, LED Indicators Charge State, OVP, OTP, SCP, Charges AGM Batteries, Max 12hrs Charging Time

DA200U-250A-R

- Output Power - 200W

- Output Volt - 24V

- Output Current - 8A

- # of ports - 1

- Features - RESNA Compliant, CEC Compliant, LED Indicators Charge State, OVP, OTP, SCP, Dual-Mode Charger, Charges GEL or AGM batteries, Max 12hrs Charging Time

What are the key differences between board-mount and brick DC/DC converters?

Board-mount and brick DC/DC converters differ significantly in size, power density, integration approach, and typical use cases. Board-mount converters are compact modules designed to be soldered directly onto a PCB. They are ideal for low to medium power applications where voltage regulation must occur close to sensitive loads such as processors, sensors, communication modules, or control logic. Their proximity to the load improves transient response and reduces voltage drop.

Brick converters are larger, standardized modules commonly available in quarter-brick, half-brick, and full-brick sizes. They are optimized for higher power delivery and are often used as centralized or intermediate bus converters in systems with substantial power demand. Brick converters usually feature higher efficiency at elevated power levels and are easier to thermally manage using heat sinks, baseplates, or forced airflow.

From an OEM perspective, the choice depends on system architecture. Distributed systems benefit from board-mount converters placed near each load, while centralized or semi-centralized systems often rely on brick converters feeding multiple downstream regulators. Each approach has implications for layout, thermal design, serviceability, and cost.

Top Benefits

-

Board-mount converters support compact, distributed power designs

-

Brick converters handle higher power with simpler thermal solutions

-

Both form factors support scalable system architectures when used correctly

Best Practices

-

Use board-mount converters for localized, lower power regulation

-

Choose brick converters for high power or intermediate bus architectures

-

Match form factor to power density and thermal dissipation needs

Understanding these differences allows OEMs to design power systems that balance efficiency, size, cost, and long term reliability.

When should OEMs choose board-mount DC/DC converters for power designs?

OEMs should consider board-mount DC/DC converters when power requirements are relatively modest and regulation must occur close to sensitive electronic loads. These converters are well suited for embedded control boards, sensor interfaces, communication modules, and multi-rail systems where several voltage levels are derived from a common input. Their small footprint allows integration directly on the PCB, reducing wiring complexity and improving signal integrity.

Board-mount converters are especially effective in space constrained designs where centralized power modules would be impractical. They also simplify assembly and reduce the need for additional mounting hardware or cabling. In distributed architectures, placing converters near the load minimizes losses and improves transient performance, which is critical for processors, FPGAs, and RF components.

However, board-mount converters are limited in power handling and thermal dissipation. As power levels rise, heat becomes more difficult to manage within the PCB area. OEMs must ensure adequate copper area, airflow, and thermal vias to prevent early derating. When these constraints can be managed, board-mount converters offer a cost effective and flexible solution.

Top Benefits

-

Enables compact and distributed power regulation

-

Improves voltage stability near sensitive loads

-

Simplifies wiring and system assembly

Best Practices

-

Validate thermal performance inside the final enclosure

-

Use sufficient copper and vias for heat spreading

-

Avoid exceeding realistic continuous power limits

Board-mount DC/DC converters are an excellent choice for localized regulation in compact systems when thermal and power limits are properly accounted for.

CLIENT'S QUOTE

Phihong's Power-Over-Ethernet solutions have transformed our network, boosting efficiency and reducing costs. Their seamless integration has simplified both installation and maintenance.

Brick DC/DC converters support higher power density and centralized architectures

Brick DC/DC converters are designed for applications where higher power levels and centralized regulation are required. In many industrial control systems, networking platforms, and automation cabinets, a brick converter is used as an intermediate bus converter that steps down a higher input voltage, such as 48 V, to a lower distribution voltage like 12 V. From there, smaller downstream converters or point of load regulators handle final voltage conversion. This approach simplifies power distribution and improves overall system efficiency.

One of the key advantages of brick converters is thermal handling. Their larger form factor allows for better heat dissipation through baseplates, heat sinks, or forced airflow. This makes them well suited for systems with sustained high power demand or elevated ambient temperatures. Brick converters are also mechanically robust, which helps in industrial environments subject to vibration or long operational lifetimes.

From a manufacturing perspective, brick converters can reduce PCB congestion by removing high power conversion stages from crowded boards. They also support standardized footprints, making it easier for OEMs to scale designs or swap power levels without a complete redesign. When power requirements exceed what board-mount converters can safely deliver, brick converters provide a reliable and scalable alternative.

Top Benefits

-

Supports higher continuous power levels

-

Simplifies thermal management at elevated loads

-

Enables centralized or intermediate bus power architectures

Best Practices

-

Use brick converters for systems above typical board-mount power limits

-

Plan airflow or heat sinking early in enclosure design

-

Pair brick converters with downstream point of load regulation

Brick DC/DC converters give OEMs a stable foundation for high power systems where efficiency, thermal performance, and scalability are critical.

Thermal and mechanical constraints often drive form factor selection

Thermal and mechanical considerations frequently determine whether board-mount or brick DC/DC converters are the better choice. Board-mount converters rely heavily on PCB copper area and local airflow to dissipate heat. In compact enclosures or fanless designs, this can limit usable power and force early thermal derating. Brick converters, by contrast, are designed to interface directly with mechanical cooling solutions, making them easier to manage thermally in demanding environments.

Mechanical integration also matters. Board-mount converters simplify assembly by eliminating cables and mounting hardware, but they compete for PCB real estate. Brick converters require mounting structures or connectors, but they free up board space and can be placed in thermally optimal locations within the enclosure. OEMs must evaluate enclosure layout, airflow paths, and serviceability when selecting a form factor.

Vibration and shock resistance are another factor. Brick converters are often more mechanically rugged and easier to secure in industrial cabinets or transportation related systems. Board-mount converters may require additional reinforcement if subjected to continuous vibration. Evaluating these mechanical realities early helps prevent reliability issues after deployment.

Top Benefits

-

Aligns converter choice with enclosure and airflow constraints

-

Improves reliability under thermal and mechanical stress

-

Reduces late stage redesigns caused by overheating or fit issues

Best Practices

-

Validate converter temperatures inside the final mechanical enclosure

-

Consider vibration and shock requirements for industrial environments

-

Balance PCB density against centralized cooling options

Form factor selection based on thermal and mechanical realities leads to power systems that perform reliably under real operating conditions.

Matching form factor to lifecycle, serviceability, and scalability goals

OEMs should consider product lifecycle and scalability when choosing between board-mount and brick DC/DC converters. Board-mount converters are often ideal for fixed designs with stable power requirements and limited service access. Once integrated, they are not easily replaced without board level repair. This is acceptable for many embedded systems but may be less desirable in high availability or service oriented applications.

Brick converters offer greater flexibility for maintenance and upgrades. Because they are often socketed or mechanically mounted, they can be replaced or upgraded without disturbing the main control board. This is valuable in industrial systems expected to operate for many years or evolve with changing power demands. Brick form factors also make it easier to scale power capacity by swapping to higher rated modules within the same footprint.

Supply chain stability is another consideration. Brick converters often follow industry standard footprints, which gives OEMs more sourcing flexibility over long production runs. Board-mount converters can be more design specific, increasing dependency on a single supplier if not planned carefully.

Top Benefits

-

Supports long term serviceability and power upgrades

-

Improves scalability for evolving system requirements

-

Reduces supply chain and lifecycle risk

Best Practices

-

Align form factor choice with expected product lifespan

-

Consider field service and upgrade requirements

-

Use standardized footprints where long term sourcing matters

Selecting the right DC/DC converter form factor with lifecycle and scalability in mind helps OEMs build power systems that remain viable and supportable for years.

How Phihong supports OEM decisions between board-mount and brick DC/DC converters

Phihong supports OEMs by offering both board-mount and brick DC/DC converter solutions designed to meet the diverse power architecture needs of modern industrial systems. Their board-mount converters are optimized for compact, distributed power regulation where efficiency, size, and proximity to sensitive loads are critical. These solutions help OEMs simplify PCB layouts, reduce wiring complexity, and maintain stable voltage regulation close to processors, sensors, and communication modules.

For higher power applications, Phihong’s brick DC/DC converters provide a robust foundation for centralized and intermediate bus architectures. These converters are engineered for high efficiency, predictable thermal behavior, and mechanical robustness, making them well suited for industrial control cabinets, automation platforms, networking systems, and robotics. Standardized brick footprints support scalability and long product lifecycles, allowing OEMs to adapt to changing power demands without full system redesigns.

Beyond hardware, Phihong provides engineering guidance, documentation, and long-term supply stability to help OEMs make informed form factor decisions early in the design process. This support reduces integration risk, shortens development timelines, and ensures power systems remain reliable across global deployments and extended service lifetimes.

Suggested links

https://www.phihong.com/internal-power-supply/

https://www.phihong.com/contact/

FEATURED RESOURCE

Phihong's Power-Over-Ethernet solutions have transformed our network, boosting efficiency and reducing costs.

FAQ

What is the main difference between board-mount and brick DC/DC converters?

The primary difference between board-mount and brick DC/DC converters lies in their intended power levels, integration approach, and thermal handling. Board-mount converters are compact modules designed to be soldered directly onto a printed circuit board. They are typically used for low to medium power applications where voltage regulation must occur close to the load. This makes them ideal for embedded control boards, sensors, communication modules, and multi-rail systems that require efficient localized regulation.

Brick DC/DC converters are larger modules designed for higher power delivery. They are often used as centralized or intermediate bus converters that feed downstream point of load regulators. Brick converters are better suited for systems with sustained high power demand, as their form factor supports improved heat dissipation through baseplates, heat sinks, or airflow.

OEMs choose between these form factors based on system architecture, power density, thermal constraints, and serviceability requirements. Understanding these differences helps ensure reliable performance and long term scalability.

When should OEMs avoid using board-mount DC/DC converters?

OEMs should avoid using board-mount DC/DC converters in applications where power demand exceeds the thermal dissipation capability of the PCB. As power levels rise, board-mount converters rely heavily on copper area and airflow to manage heat. In sealed enclosures or high ambient environments, this can lead to early thermal derating or reliability issues.

Board-mount converters may also be unsuitable in systems that require frequent service or upgrades. Because they are soldered directly onto the board, replacing or upgrading them typically requires board level repair. In industrial systems with long service lifetimes or evolving power requirements, this can be a limitation.

Finally, board-mount converters may not be ideal in environments with high vibration unless additional mechanical support is provided. OEMs should carefully evaluate environmental conditions, power levels, and lifecycle expectations before selecting a board-mount solution.

Why are brick DC/DC converters preferred for higher power industrial systems?

Brick DC/DC converters are preferred in higher power systems because they offer superior thermal handling, mechanical robustness, and scalability. Their larger size allows for better heat dissipation, which is essential in industrial control cabinets, automation platforms, and networking equipment that operate continuously. Brick converters can be mounted to heat sinks or chassis surfaces, making thermal management more predictable and effective.

Brick converters also support standardized footprints, such as quarter-brick or half-brick formats. This standardization allows OEMs to scale power capacity or change suppliers with minimal redesign. In addition, brick converters are often easier to service or replace in the field, which is valuable in mission critical systems.

For OEMs building systems with high power density or long operational lifetimes, brick converters provide a stable and future proof power foundation.

How does form factor selection impact long term reliability and maintenance?

Form factor selection directly affects how a power system ages and how easily it can be maintained. Board-mount converters, when used within their thermal and electrical limits, offer reliable performance with minimal complexity. However, because they are embedded into the PCB, failures often require board replacement or repair, which may not be practical in the field.

Brick converters, by contrast, are typically more accessible and replaceable. This makes them attractive for systems that require high availability or long service intervals. Brick form factors also allow OEMs to plan for future upgrades by reserving space for higher power modules if demand increases.

Choosing the appropriate form factor based on reliability and maintenance goals helps OEMs minimize downtime, reduce service costs, and extend product lifespan.

Why should OEMs work with Phihong for DC/DC converter form factor selection?

Phihong offers OEMs a comprehensive portfolio of board-mount and brick DC/DC converters backed by decades of power engineering experience. Their products are designed for efficiency, predictable thermal behavior, and compliance with global standards. This allows OEMs to select form factors that align with both current requirements and future scalability.

Phihong also provides detailed documentation, engineering support, and long product lifecycles. OEMs benefit from consistent manufacturing quality and reliable supply chains, which reduce redesign risk over extended production runs.

By partnering with Phihong, OEMs gain access to trusted power solutions and expert guidance that simplify form factor decisions and support robust, long term power system designs.