BLOG

PoE++ Switch OEM Guide: How to Deploy 802.3bt Gear for Smart-Factory Edge Sensors

Table of contents

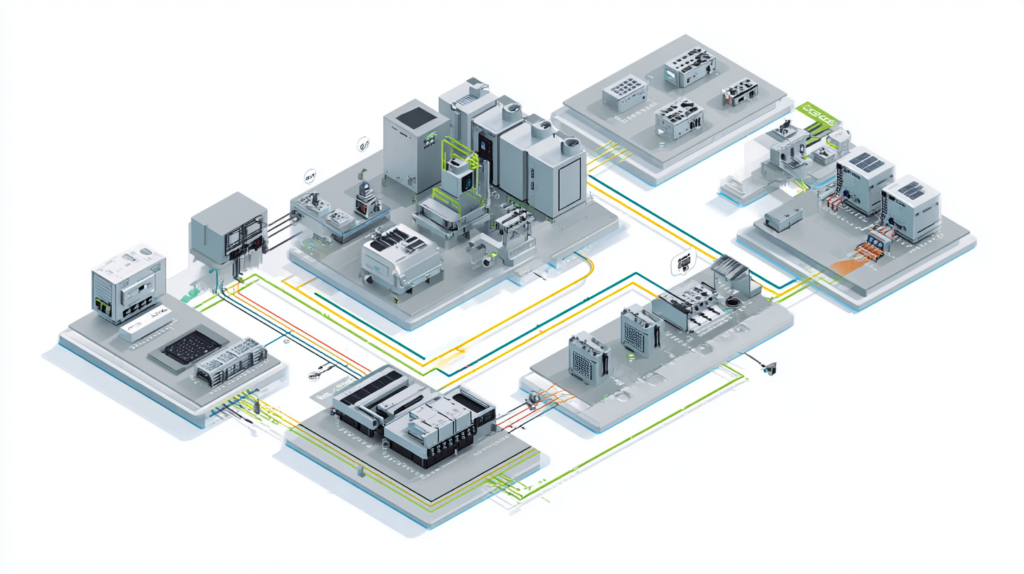

Why 802.3bt PoE++ Technology Is Essential for Smart Factory Infrastructure

As smart factories advance, the demand for higher power delivery over Ethernet cables has accelerated. Legacy PoE (IEEE 802.3af and 802.3at) can no longer support the full power needs of edge computing devices, machine vision sensors, robotic nodes, and multi-sensor gateways. That’s where 802.3bt, or PoE++, steps in—offering up to 90 watts per port.

Unlike traditional PoE that supplies around 15–30 watts, PoE++ opens the door to power-hungry industrial applications such as pan-tilt-zoom (PTZ) surveillance cameras, HMI panels, AI inference edge devices, and even compact robotic modules. OEMs integrating smart factory solutions need robust, scalable, and compliant PoE++ switch designs to support this power evolution.

This is especially critical in smart factories where:

- Devices are deployed in harsh environments

- Cabling simplicity and reliability are top priorities

- Downtime and power loss are unacceptable

By enabling power and data over a single cable, PoE++ helps reduce clutter, lower maintenance, and improve overall reliability—key benefits in today’s Industry 4.0 deployments.

Top Features

- Delivers up to 90 W per port under IEEE 802.3bt Type 3 & 4 standards

- Supports backward compatibility with PoE/PoE+ devices

- Enhanced power negotiation via LLDP and intelligent PSE firmware

Top Benefits

- Eliminates need for local power at device endpoints

- Simplifies deployment of intelligent factory sensors and controllers

- Reduces cabling and power supply costs across production floors

Best Practices

- Validate end device power classification and thermal thresholds

- Use shielded Cat6a or Cat7 cable for longer distance/high wattage

- Ensure switch firmware supports dynamic power reallocation

PoE++ is the bridge between Ethernet simplicity and industrial power—essential for smart sensor integration at the edge.

How PoE++ Enables High-Power Edge Devices in Industrial Settings

Smart factories rely on real-time decision-making at the edge—from vision processing and sensor fusion to AI model execution and data filtering. These edge devices often require 40–70 W continuously, making 802.3bt the only viable PoE standard that supports them reliably over long runs.

Common examples include:

- LIDAR systems and 3D vision cameras for robotic guidance

- Edge AI gateways that preprocess machine data before cloud sync

- Industrial PLCs with advanced diagnostics or integrated HMIs

- Smart lighting and building management devices

The use of PoE++ avoids placing AC power adapters near production lines, improving safety and minimizing equipment failure due to poor cabling or EMI. And since 802.3bt supports up to 10 Gbps, data bandwidth keeps pace with high-resolution vision or sensor arrays.

Top Features

- 90 W sustained power at PD (Powered Device) side

- 10 Gbps data transmission over shielded Ethernet

- Active power management to prioritize critical loads

Top Benefits

- Powers AI edge processors and sensor hubs without additional wiring

- Increases mobility and modularity of factory equipment

- Enables faster deployment and minimal downtime in retrofit upgrades

Best Practices

- Match PSE power budget to worst-case PD draw scenarios

- Use industrial-rated connectors and sealed enclosures

- Validate PoE signature handshake timing for each sensor type

With PoE++, OEMs can confidently deploy high-wattage edge systems in challenging factory environments with minimal compromise.

Design Considerations for OEMs Building PoE++ Switches

Building a reliable 802.3bt PoE++ switch requires more than just meeting wattage specs. It demands careful attention to thermal design, power negotiation, fault protection, and compliance with surge and EMC standards.

OEMs should incorporate:

- Efficient DC-DC converters with low ripple for stable PD operation

- Accurate power monitoring ICs to prevent overload conditions

- Advanced firmware for real-time LLDP and dynamic power management

- Integrated ESD and surge protection for industrial reliability

Form factor also matters. OEM switches for factory settings are often DIN-rail mounted or rack-integrated. They must tolerate 60–70°C ambient temps and support rugged operation with MTBF ratings of 500K+ hours.

Top Features

- PSE controllers with Type 3 & 4 compliance

- Onboard telemetry for voltage, current, and temperature per port

- Redundant input power options (e.g., 48–57 VDC)

Top Benefits

- Prevents brownout conditions under simultaneous load

- Allows real-time diagnostics via SNMP or REST APIs

- Scales seamlessly across 8, 16, or 24-port designs

Best Practices

- Test with both compliant and borderline PDs to ensure handshake integrity

- Design heat sinking around power stages, not just chassis vents

- Pre-certify against IEC 61000 surge/EMC for faster time to market

PoE++ switch design is not trivial—but with the right strategy, OEMs can build rugged, scalable hardware for the Industry 4.0 edge.

CLIENT'S QUOTE

"Phihong’s PoE solutions have made a huge difference for us! Our network runs more efficiently, and we’ve seen real cost savings. We couldn’t be happier!"

What to Look for in PoE++ Cabling and Connectors for Harsh Environments

Delivering 90 W continuously over Ethernet requires high-quality, shielded cabling and ruggedized connectors. OEMs must specify components that can survive not just high temperatures and vibration, but also EMI from motors, welding systems, and high-speed automation.

For 802.3bt:

- Cat6a or Cat7 cable is strongly recommended for 90 W operation

- Shielded connectors prevent interference and cross-talk

- Locking or sealed RJ45 jacks prevent signal loss from vibration

Industrial applications may also use M12 connectors for factory-grade environments, offering IP67 or higher protection and excellent durability under repeated insertion.

Top Features

- Shielded twisted-pair (STP) construction

- Strain-relief jackets and cable glands

- IP-rated connectors for dust, oil, and moisture resistance

Top Benefits

- Prevents data loss and power sag in noisy electrical zones

- Increases service life of smart sensors and control panels

- Enables consistent high-wattage delivery at 100m distance

Best Practices

- Always test cable runs with certified 802.3bt test equipment

- Consider thermal rise within cable bundles during full power draw

- Use color-coded labeling and shielding maps for PoE++ routing

Cabling is the nervous system of a smart factory—and PoE++ deployments require stronger nerves than ever before.

Managing Power Budgets and Load Prioritization in 802.3bt Switches

Not every port on a PoE++ switch will draw 90 W all the time. But cumulative power budgeting is crucial. OEMs must design systems that:

- Monitor per-port and total switch power draw

- Reallocate power dynamically as devices come and go

- Prioritize mission-critical ports when power demand exceeds supply

Advanced PSE controllers and intelligent switch firmware can classify PDs (Powered Devices) based on LLDP negotiation, and implement load shedding or throttling under constrained conditions.

Additionally, integrating backup power (UPS or battery modules) allows PoE++ switches to maintain uptime during grid instability or brownouts.

Top Features

- Port-level power monitoring with dynamic reallocation

- Firmware-based class override and prioritization logic

- Total PSE power cap and per-port enforcement

Top Benefits

- Prevents brownout or unexpected resets from overdraw

- Supports smarter power provisioning across mixed-load deployments

- Enhances fault tolerance and uptime for edge devices

Best Practices

- Simulate overload conditions during validation to confirm fallback logic

- Allow user-adjustable thresholds and alerts via management UI

- Include power logging for root-cause failure analysis

Smarter power budgeting makes PoE++ viable even in power-constrained or battery-backed edge environments.

How Phihong USA Supports OEMs in PoE++ Switch Development

Phihong USA is a global leader in PoE power solutions, including 802.3bt-ready PSE modules, injectors, and switch reference designs. We help OEMs design and deploy PoE++ hardware that meets the highest standards of industrial performance, safety, and efficiency.

We offer:

- 802.3bt PSE modules (single and multi-port)

- High-wattage PoE++ injectors with thermal protection

- Reference designs for 90 W PoE switches with LLDP support

- Telemetry-ready PSE controllers with firmware customization

- Industrial-grade surge, EMI, and thermal compliance support

Phihong supports full engineering collaboration, from concept to certification, enabling OEMs to launch rugged, high-performance smart factory equipment faster.

Ready to power the edge with PoE++? Contact usasales@phihongusa.com or visit www.phihong.com to start building.

Contact Our Team Today!

Our dedicated sales team and international partners are prepared to support you with your latest projects and initiatives globally.

Explore More with Phihong USA

As we conclude our exploration of PoE technology, it’s evident how these innovations are streamlining power and data integration across various industries. Phihong USA stands at the forefront of this technological advancement, offering a diverse range of power solutions designed to meet the evolving needs of modern industries.

Phihong USA’s extensive product lineup includes:

- Power over Ethernet (PoE) Solutions: Delivering reliable power and data transmission over a single cable, ideal for simplifying network installations and reducing costs.

- AC/DC Adapters and Power Supplies: From compact adapters to industrial-grade power supplies, Phihong provides solutions that ensure efficiency and reliability in various applications.

- Battery Chargers: Customizable chargers for lithium-ion and lead-acid batteries, supporting a wide range of power requirements for mobility and industrial applications.

- Medical Power Supplies: Specialized power solutions designed to meet the stringent requirements of the healthcare industry, ensuring safety and reliability.

Phihong USA is committed to innovation and excellence, continually developing products that meet the highest standards of performance and reliability. Their global reach and dedication to customer support make them a trusted partner in powering the future.

Here are some useful links to explore Phihong USA’s offerings further and bring in new potential clients:

Visit Phihong USA to discover how their advanced power solutions can support your business needs. Whether you’re looking to upgrade your network, or find reliable power supplies, Phihong USA has you covered.

By choosing Phihong USA, you’re partnering with a leader in power technology, ensuring your operations run smoothly and efficiently with top-tier power solutions. Contact Us today!

FAQ

What is the maximum power per port under 802.3bt PoE++?

802.3bt, known as PoE++, allows up to 90 W input at the PSE (Power Sourcing Equipment) side and up to 71.3 W available at the PD (Powered Device). This is achieved by using all four twisted pairs in the Ethernet cable and managing power using either Type 3 (up to 60 W) or Type 4 (up to 90 W) classifications.

Type 3 supports:

- 51–60 W at the PSE

- ~51 W at the PD after line loss

Type 4 supports:

- Up to 90 W at the PSE

- ~71.3 W at the PD

This makes PoE++ suitable for advanced edge devices like PTZ cameras, touchscreens, AI modules, and even low-power robotic arms, all powered over a single Ethernet connection.

Is PoE++ backward compatible with PoE and PoE+ devices?

Yes. PoE++ switches and injectors are fully backward compatible with previous IEEE standards:

- 802.3af (PoE – up to 15.4 W)

802.3at (PoE+ – up to 30 W)

PSE devices with intelligent controllers will detect the power signature of connected PDs and automatically adjust power delivery. This allows OEMs to deploy PoE++ infrastructure while still supporting legacy or low-power sensors in the same environment.In addition to its core functionality, PoE++ also incorporates advanced features for power management and efficiency.

These include load balancing, which distributes power evenly among connected devices, preventing overloads and ensuring stable operation. Power monitoring tools provide real-time insights into power consumption, allowing administrators to track usage and identify potential issues. Furthermore, PoE++ supports remote power cycling, enabling the restart of connected devices remotely, reducing the need for on-site interventions.

The implementation of PoE++ technology can significantly impact network design and deployment strategies. It allows for greater flexibility in placing devices, as power outlets are no longer a primary constraint. This is particularly beneficial in environments where physical space is limited or where running new electrical lines would be challenging. By centralizing power distribution through the network infrastructure, PoE++ also simplifies cable management and reduces overall installation complexity. This streamlined approach not only saves time and costs during initial deployment but also facilitates ongoing maintenance and upgrades.

Can I use standard Cat5e cable for PoE++?

While PoE++ may function on high-quality Cat5e cable for short distances, it is strongly recommended to use Cat6a or Cat7 shielded cable. Higher category cables:

- Reduce insertion loss and signal degradation

- Support higher current without overheating

- Provide better EMI protection in industrial settings

Always test cables under full load and over maximum intended distances. For 90 W applications, shielded Cat6a is the minimum safe standard.

In addition to the technical requirements, consider the long-term scalability and manageability of the cabling infrastructure. Utilizing higher category cables and thorough testing upfront simplifies future upgrades and troubleshooting. Documenting the cable layout, test results, and specifications will be invaluable for maintenance and expansion. Implementing cable management solutions like labeled patch panels and organized cable trays further reduces clutter and potential errors during maintenance.

Furthermore, when selecting cable suppliers, prioritize those that adhere to industry standards and provide robust warranties. Request certifications and test reports for each batch of cable to ensure consistent quality and performance. Conducting regular inspections and maintenance checks on the cabling infrastructure will also help to identify and address any potential issues before they lead to system failures. This proactive approach to cable management and maintenance ensures a stable and reliable PoE++ network, supporting the critical functions of the smart-factory edge sensor deployments.

How do smart switches manage PoE++ power distribution?

Smart PoE++ switches use embedded firmware and PSE controllers to:

- Detect PD power class (via LLDP or physical signature)

- Allocate power based on class priority or manual override

- Reclaim and reallocate power when devices disconnect

- Throttle low-priority ports during brownouts

OEMs can also enable SNMP or REST APIs to manage this logic remotely—ideal for smart factory monitoring systems.Smart Power over Ethernet Plus Plus (PoE++) switches utilize sophisticated embedded firmware and Power Sourcing Equipment (PSE) controllers to intelligently manage power distribution to connected Powered Devices (PDs). This process involves several key steps.

First, the switch actively detects the power class of each connected PD, typically using Link Layer Discovery Protocol (LLDP) or by analyzing the physical signature of the device. This initial identification is crucial for determining the power requirements of each individual device.

Based on the detected power class, the smart switch allocates power to the PDs. This allocation can be based on predefined class priorities, ensuring that critical devices receive the necessary power first, or it can be manually overridden by an administrator for specific configuration needs. This flexibility allows for optimization of power distribution according to the specific demands of the deployment environment.

Furthermore, these switches are designed to dynamically manage power resources. When a PD disconnects, the switch automatically reclaims the previously allocated power and makes it available for other connected devices. This efficient reallocation ensures that power resources are utilized effectively and minimizes waste.

In situations where the power supply experiences brownouts or power fluctuations, the smart switches are capable of throttling the power output to low-priority ports. This protective measure helps maintain power delivery to essential devices during periods of reduced power availability, ensuring system stability and preventing critical failures.

For enhanced management and monitoring capabilities, Original Equipment Manufacturers (OEMs) have the option to enable Simple Network Management Protocol (SNMP) or Representational State Transfer (REST) APIs. These interfaces allow for remote management of the power distribution logic, making them particularly valuable for integration with smart factory monitoring systems. With remote management, administrators can monitor power consumption, adjust allocations, and troubleshoot issues from a central location, optimizing the operation of the smart factory network.

How does Phihong differ from other PoE++ solution providers?

Phihong is uniquely positioned with:

- Deep expertise in PoE technology dating back to early 802.3af

- In-house manufacturing and design of injectors, PSE modules, and PD adapters

- 802.3bt-compliant reference designs for fast OEM integration

- A global reputation for quality, compliance, and long lifecycle support

We serve major industrial OEMs and networking brands, offering everything from evaluation kits to production-ready modules.