BLOG

The Future of Contactless Robot Charging: Wireless and Inductive Solutions for Dusty, Wet, or Mobile Environments

QUICK LINKS

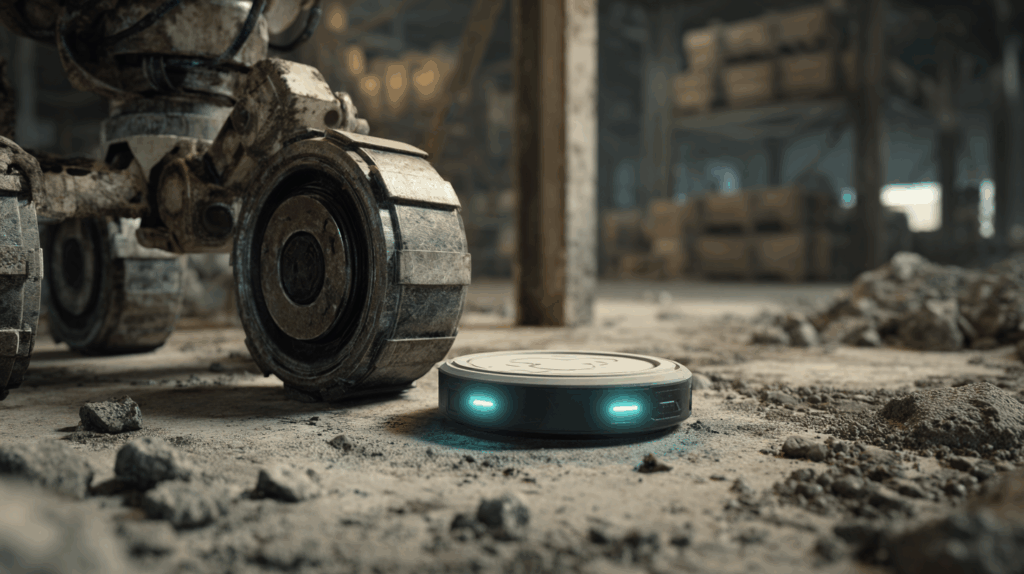

As autonomous robots continue expanding into logistics, agriculture, cleaning, and delivery, one recurring challenge stands in the way of reliability: the physical connector. Traditional conductive charging solutions—while effective—are vulnerable to dust, water, misalignment, corrosion, and mechanical wear.

Enter the next frontier: contactless robot charging through wireless and inductive technologies. These systems eliminate the need for physical plugs, enabling robots to charge through magnetic fields or resonant coupling, even in environments that are too hazardous, dirty, or dynamic for conventional connectors.

In this article, we’ll explore how wireless and inductive charging is reshaping robot infrastructure, where it’s being deployed today, and what it means for the future of rugged, hands-free, and scalable power delivery in harsh environments.

What Is Contactless Robot Charging?

Contactless charging uses electromagnetic induction or resonant energy transfer to deliver power from a transmitter pad to a receiver built into the robot—without physical contact between surfaces.

Top Features

- Air-gap power transfer through magnetic coils or resonators

- Alignment tolerance ranges from millimeters to several centimeters

- Integrated charging coils in robot chassis and docking pads

- Closed-loop power regulation via wireless communication protocols

Top Benefits

- No mechanical wear, extending dock and robot lifespan

- Fully sealed enclosures, ideal for dusty or wet environments

- Hands-free operation, perfect for 24/7 autonomous fleets

- Eliminates alignment complexity in uneven terrain or mobile use

Best Practices

- Design coil orientation and distance for optimal coupling efficiency

- Use shielding to reduce EMI and comply with FCC/CE limits

- Integrate charging logic with the robot’s battery management system (BMS)

- Test for thermal rise during continuous charging cycles

Contactless systems transform charging from a precision mechanic task into a magnetic handshake.

Why Contactless Charging Is Ideal for Harsh or Mobile Environments

Robots deployed in outdoor, industrial, or dynamic settings often struggle with debris, vibration, and water—making contactless charging not just ideal, but essential.

Top Use Cases

- Outdoor delivery robots in rain, snow, or dust-prone sidewalks

- Agricultural robots exposed to irrigation systems and mud

- Warehouse AMRs operating on shifting floors with vibration

- Cleaning robots in high-humidity environments like malls or airports

Key Benefits

- No exposed metal surfaces to corrode, short, or clog

- Greater mechanical flexibility for moving robots and flexible docks

- Enables multi-axis alignment for fast docking, even with imperfect navigation

- Reduces downtime from failed or misaligned charging attempts

Best Practices

- Match IP68 enclosures with contactless designs for true waterproofing

- Use magnetic alignment aids or vision-assisted docking to improve efficiency

- Evaluate RF interference risks in high-traffic radio environments

- Include fallback protocols for failed energy handshakes

In extreme environments, removing the plug entirely is the most reliable solution.

CLIENT'S QUOTE

"Phihong’s PoE solutions have made a huge difference for us! Our network runs more efficiently, and we’ve seen real cost savings. We couldn’t be happier!"

Comparing Wireless, Inductive, and Resonant Charging Technologies

Not all contactless systems are created equal—each approach offers different trade-offs in efficiency, distance, and alignment tolerance.

Inductive Charging

- Requires tight coil alignment (1–5 mm)

- High efficiency (90%+) at close range

- Widely used in consumer electronics and medical devices

- Ideal for flat-surface docking environments

Resonant Wireless Charging

- Supports looser alignment (up to 20–50 mm)

- Moderate efficiency (70–85%)

- Better suited for mobile or high-clearance robots

- Offers flexible design with air gaps or curved surfaces

RF or Microwave Charging (Emerging)

- Long-distance energy beaming (meters)

- Low efficiency, still experimental for robotics

- Suitable for low-power IoT or sensor bots, not large fleets (yet)

Best Practices

- Choose inductive for tight spaces with controlled alignment

- Choose resonant for outdoor/mobile bots with variable terrain

- Consider combining contactless charging with capacitor-based quick top-offs

- Always comply with regulatory guidelines for wireless power transfer

The goal isn’t just power—it’s reliability in uncontrolled conditions.

The Challenges of Contactless Charging—and How to Overcome Them

Despite its advantages, contactless charging presents engineering and cost challenges that must be carefully addressed.

Common Challenges

- Lower efficiency than conductive systems in many configurations

- Thermal buildup due to energy loss during magnetic coupling

- Costlier components (coils, shielding, specialized drivers)

- Alignment precision remains a factor in real-world deployments

Engineering Solutions

- Improve efficiency with tightly coupled coil design and smart BMS logic

- Add thermal sensors and active cooling in charging base

- Use auto-calibration to adjust power output based on alignment quality

- Test coil enclosures with multi-axis misalignment simulations

Contactless charging works—but it must be designed holistically with the robot and deployment environment in mind.

Industry Trends and Adoption by Leading OEMs

Top robotics companies are now investing in contactless charging platforms, particularly for fleets operating outdoors or across mixed-use spaces.

Industry Examples

- Autonomous delivery bots with side-panel inductive charging for curbside docks

- Airport floor-cleaning robots using wireless pads embedded in storage closets

- Agricultural equipment charging from drive-through inductive stations

- Logistics AMRs using on-the-go opportunity charging at transfer zones

Key Drivers

- Reduced maintenance and service costs

- IP-rated compliance for ruggedized environments

- 24/7 autonomy without operator intervention

- Fleet reliability in unpredictable charging conditions

OEM Strategy

- Early adopters are using hybrid systems: contactless charging for day-to-day, conductive backups for emergencies

- Future-forward OEMs are partnering with wireless charging infrastructure providers to co-design scalable platforms

- Smart city initiatives are favoring embedded, wireless curbs and sidewalks for delivery bot integration

Contactless isn’t just a feature—it’s a strategic advantage for next-gen robot OEMs.

How Phihong USA Supports Contactless Charging Infrastructure

Phihong USA is at the forefront of next-generation charging technology, offering modular power systems ready for integration with inductive and wireless energy platforms. We support:

- AC-DC and DC-DC modules optimized for inductive coupling

- Smart charging drivers with BMS handshake protocols

- Thermal protection and surge suppression for wireless platforms

- IP68-rated enclosures and connectors for embedded charging infrastructure

- Engineering support for integration, compliance, and thermal simulation

Whether you’re designing a delivery robot, industrial sweeper, or agricultural platform, Phihong helps you cut the cord—without cutting reliability.

Contact Our Team Today!

Our dedicated sales team and international partners are prepared to support you with your latest projects and initiatives globally.

Explore More with Phihong USA

As we conclude our exploration of PoE technology, it’s evident how these innovations are streamlining power and data integration across various industries. Phihong USA stands at the forefront of this technological advancement, offering a diverse range of power solutions designed to meet the evolving needs of modern industries.

Phihong USA’s extensive product lineup includes:

- Power over Ethernet (PoE) Solutions: Delivering reliable power and data transmission over a single cable, ideal for simplifying network installations and reducing costs.

- AC/DC Adapters and Power Supplies: From compact adapters to industrial-grade power supplies, Phihong provides solutions that ensure efficiency and reliability in various applications.

- Battery Chargers: Customizable chargers for lithium-ion and lead-acid batteries, supporting a wide range of power requirements for mobility and industrial applications.

- Medical Power Supplies: Specialized power solutions designed to meet the stringent requirements of the healthcare industry, ensuring safety and reliability.

Phihong USA is committed to innovation and excellence, continually developing products that meet the highest standards of performance and reliability. Their global reach and dedication to customer support make them a trusted partner in powering the future.

Here are some useful links to explore Phihong USA’s offerings further and bring in new potential clients:

Visit Phihong USA to discover how their advanced power solutions can support your business needs. Whether you’re looking to upgrade your network, or find reliable power supplies, Phihong USA has you covered.

By choosing Phihong USA, you’re partnering with a leader in power technology, ensuring your operations run smoothly and efficiently with top-tier power solutions. Contact Us today!

FAQ

What is contactless charging for robots?

Contactless charging refers to wireless power transfer methods that allow robots to recharge without physical connectors. The most common forms are inductive charging (short-range magnetic coils) and resonant charging (slightly longer range, more alignment flexibility). These systems improve reliability in wet, dusty, or mobile environments by removing vulnerable contact points. They’re widely used in autonomous robots that operate outdoors or in continuous-motion scenarios.

Is contactless charging less efficient than wired charging?

Generally, yes. Contactless charging systems are 5–15% less efficient than traditional conductive systems, depending on alignment and coil design. However, the trade-off is greater reliability, reduced maintenance, and improved safety. With modern coil design and power electronics, some inductive systems now achieve 90%+ efficiency, making them suitable for mission-critical robots. Optimization and proper design can narrow the efficiency gap considerably.

What are the main challenges of using wireless robot charging?

Key challenges include:

- Thermal buildup from inefficient coupling

- Precise alignment in real-world environments

- Component cost of coils, shielding, and power drivers

- EMI compliance and regulatory certification

To address these, manufacturers must invest in thermal modeling, automated alignment, and advanced BMS integration. Partnering with power experts ensures these issues are mitigated early in the design process.

Are contactless charging stations weatherproof?

Yes—contactless systems are often more weatherproof than conductive systems because they eliminate exposed pins or contacts. Charging coils and electronics are enclosed in fully sealed IP67/IP68-rated housings, making them ideal for rain, snow, mud, and debris-prone environments. Contactless charging is a strong fit for sidewalk delivery, agriculture, and public-area cleaning robots.

How does Phihong help OEMs implement contactless robot charging?

Phihong USA provides a range of wireless and inductive-ready power modules, including smart AC-DC drivers, IP-rated enclosures, and thermal-protected charging components. We support OEMs with:

- Power architecture for inductive and resonant charging

- BMS integration for safe, efficient energy delivery

- Environmental and thermal testing for outdoor use

- Compliance consulting for EMI, FCC, and CE certification

Phihong’s experience in industrial-grade power delivery ensures your contactless charging solution is robust, scalable, and field-ready.