BLOG

What Is the Best Thermal Management Solution for Outdoor Robot Charging Stations in Freezing Conditions?

QUICK LINKS

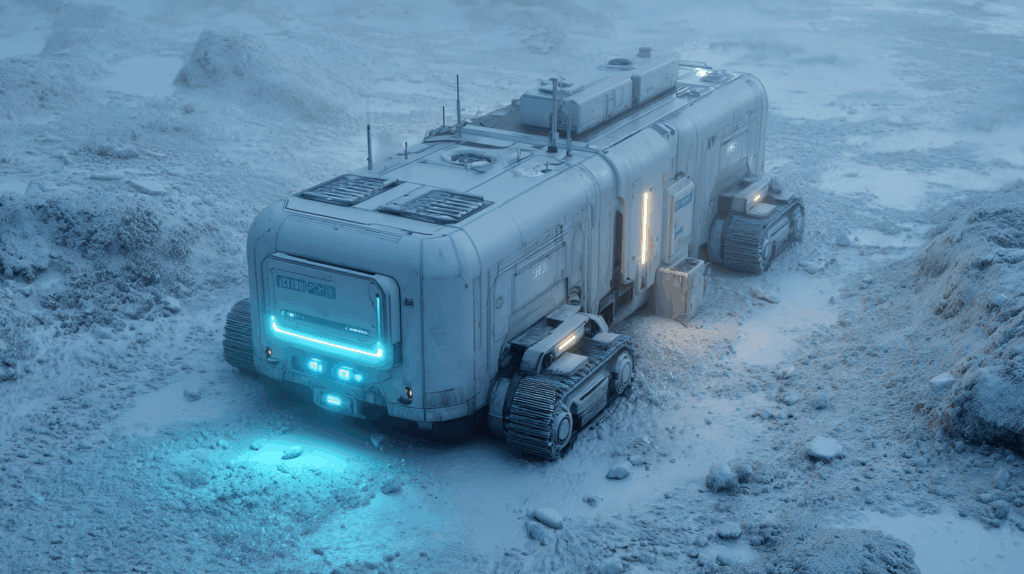

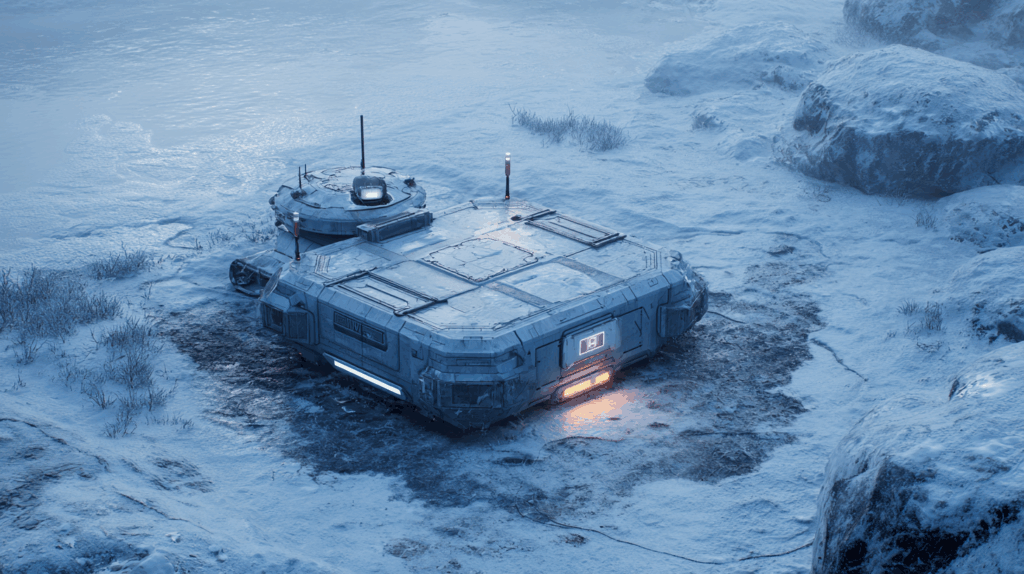

As autonomous robots increasingly take on roles in delivery, maintenance, agriculture, and security, their use is expanding into cold-climate regions where freezing temperatures, snow, and ice are part of daily operations. In these challenging environments, robot performance hinges not just on battery chemistry or navigation—but on the thermal integrity of the charging infrastructure.

Outdoor charging stations must now do more than deliver power—they must regulate temperature, prevent condensation, and ensure safe startup and shutdown of robotic systems exposed to sub-zero conditions. For OEMs, integrators, and operators, this marks a turning point in how thermal management is designed, implemented, and maintained in robotic docking systems.

In this article, we’ll examine how cold-weather robot deployments are redefining charging station requirements, the thermal risks to avoid, and the technologies enabling year-round autonomous operation in extreme climates.

Why Cold Weather Poses Unique Challenges for Robot Charging Systems

Low temperatures dramatically affect battery performance, power conversion efficiency, and mechanical systems. For charging docks, these conditions introduce risks that require proactive thermal engineering.

Key Risks

- Battery degradation or failure due to charging at freezing temperatures

- Condensation and ice formation inside enclosures

- Sluggish or failed charging cycles due to power module inefficiency

- Physical damage to connectors from frost expansion or thermal cycling

Top Features for Cold-Climate Support

- Integrated dock heaters and thermostats

- Wide-temperature-rated power supplies (-40 °C to +85 °C)

- Humidity control and condensation prevention systems

- Thermal-insulated enclosures with snow-shedding geometry

Best Practices

- Delay charging until batteries reach minimum temperature thresholds

- Seal all electronic compartments to avoid ingress of ice, salt, or snow

- Use conformal-coated PCBs and corrosion-resistant contacts

- Test dock behavior under both static cold and temperature cycling

Without proper thermal design, a robot may arrive at its dock—but fail to recharge—turning a successful mission into a costly delay.

How Thermal Management Is Being Integrated into Outdoor Charging Stations

Thermal regulation is no longer a secondary feature—it is a core functional requirement for charging systems supporting robots in northern cities, mountain regions, or polar industrial zones.

Top Thermal Management Technologies

- Thermostatically controlled dock heaters: Activate heating only when ambient temps fall below a set point

- Thermal insulation barriers: Reduce heat loss and prevent internal freezing

- PTC (Positive Temperature Coefficient) heating elements: Self-regulate heat output to prevent overheating

- Vent membranes: Allow pressure equalization while blocking water ingress

Top Benefits

- Keeps battery packs within safe charging temperature range

- Prevents electronics from cracking, freezing, or corroding

- Supports continuous 24/7 robot operation through winter months

- Reduces maintenance calls due to frost-related connector failures

Best Practices

- Include thermal sensors in both robot and dock to coordinate heating cycles

- Use edge processors for local temperature-based charging logic

- Integrate over-temp and under-temp shutdown thresholds to prevent damage

- Design for snow accumulation runoff and easy de-icing maintenance

Thermal design isn’t just about comfort—it’s about operational survivability.

Designing Power Electronics That Perform in Sub-Zero Conditions

The efficiency and safety of a robot charging station in cold climates depend heavily on power electronics engineered for extreme temperatures.

Top Features

- Wide-temp AC-DC and DC-DC modules rated for -40 °C to +85 °C

- Active power factor correction (PFC) that works in low temperatures

- Low ESR capacitors and thermally stable semiconductors

- Conformal coatings or potting for board-level frost resistance

Top Benefits

- Maintains stable voltage output in low ambient conditions

- Avoids brownouts or current spikes during early-morning or overnight charging

- Reduces power loss caused by cold-induced inefficiencies

- Extends lifetime of internal power systems in harsh environments

Best Practices

- Derate power modules slightly to handle cold startup stress

- Choose MOSFETs and drivers rated for polar industrial use

- Monitor output ripple and efficiency under simulated field frost tests

- Apply surge suppression for winter lightning or power instability events

Sub-zero reliability starts with components that don’t crack, stall, or short when the temperature drops.

CLIENT'S QUOTE

"Phihong’s PoE solutions have made a huge difference for us! Our network runs more efficiently, and we’ve seen real cost savings. We couldn’t be happier!"

Cold-Climate Installation and Maintenance Considerations

Thermal performance also depends on how and where the dock is installed. Location, maintenance access, and environmental exposure all affect real-world usability.

Key Considerations

- Ground mounting: Raise docks slightly to prevent snow burial or flood damage

- Sun exposure: Leverage daytime heating to offset overnight cold cycles

- Drainage design: Prevent water and slush from refreezing inside cable paths

- Field servicing: Provide heated access panels or cold-rated gloves for technicians

Best Practices

- Add anti-slip or de-icing surface coatings to public-facing installations

- Provide visual cues (LED indicators) for dock activity, visible through frost or snow

- Use weatherproof covers or retractable hoods for robots not charging

- Include QR-code access to maintenance logs and firmware controls for field staff

It’s not enough to build cold-proof hardware—you need installation practices that account for real-world field conditions.

How Cold-Climate Requirements Influence Smart Dock Communication

Smart charging docks must adapt behavior based on temperature feedback—not just from the dock, but from the robot’s BMS and local edge processors.

Top Features

- CANBus or UART-based temperature signal exchange

- AI-powered thermal profile learning from past charging behavior

- Remote diagnostics for temperature trends and fault analysis

- OTA firmware updates to adjust heating thresholds or logic

Top Benefits

- Prevents unsafe charging based on live environmental conditions

- Optimizes power delivery for energy efficiency in cold cycles

- Detects anomalies such as blocked airflow, frozen cables, or heating failure

- Enables proactive maintenance with thermal event logging

Best Practices

- Align temperature response behavior between robot and dock firmware

- Store thermal performance data to refine future firmware updates

- Notify fleet managers of below-threshold charging attempts or failures

- Include failsafe behavior if thermal sensors are compromised

Charging in the cold isn’t just about turning on a heater—it’s about intelligent thermal orchestration across the system.

How Phihong USA Supports Cold-Climate Robot Charging Systems

Phihong USA provides ruggedized, wide-temperature, and thermally managed charging systems for mobile robots deployed in extreme climates. We support OEMs with:

- AC-DC and DC-DC modules rated down to -40 °C

- Heated, IP67-rated enclosures with anti-ice design features

- Smart dock control boards with thermal sensors and edge logic

- Engineering support for insulation, thermal simulations, and outdoor installations

- Compliance-ready solutions for UL, CE, and IEC certifications in cold-weather environments

From northern cities to snowy logistics hubs, Phihong delivers charging infrastructure built to survive winter—without compromise.

Contact Our Team Today!

Our dedicated sales team and international partners are prepared to support you with your latest projects and initiatives globally.

Explore More with Phihong USA

As we conclude our exploration of PoE technology, it’s evident how these innovations are streamlining power and data integration across various industries. Phihong USA stands at the forefront of this technological advancement, offering a diverse range of power solutions designed to meet the evolving needs of modern industries.

Phihong USA’s extensive product lineup includes:

- Power over Ethernet (PoE) Solutions: Delivering reliable power and data transmission over a single cable, ideal for simplifying network installations and reducing costs.

- AC/DC Adapters and Power Supplies: From compact adapters to industrial-grade power supplies, Phihong provides solutions that ensure efficiency and reliability in various applications.

- Battery Chargers: Customizable chargers for lithium-ion and lead-acid batteries, supporting a wide range of power requirements for mobility and industrial applications.

- Medical Power Supplies: Specialized power solutions designed to meet the stringent requirements of the healthcare industry, ensuring safety and reliability.

Phihong USA is committed to innovation and excellence, continually developing products that meet the highest standards of performance and reliability. Their global reach and dedication to customer support make them a trusted partner in powering the future.

Here are some useful links to explore Phihong USA’s offerings further and bring in new potential clients:

Visit Phihong USA to discover how their advanced power solutions can support your business needs. Whether you’re looking to upgrade your network, or find reliable power supplies, Phihong USA has you covered.

By choosing Phihong USA, you’re partnering with a leader in power technology, ensuring your operations run smoothly and efficiently with top-tier power solutions. Contact Us today!

FAQ

Why is thermal management important for robot charging stations in cold climates?

In cold temperatures, batteries can become damaged or inefficient when charged below their minimum thermal threshold. Without thermal management, charging docks risk battery swelling, reduced capacity, and even permanent failure. Cold can also cause moisture ingress, condensation on PCBs, and connector damage. Proper thermal design ensures the station can safely initiate and complete charge cycles, even during freezing weather.

What technologies help charging docks perform in sub-zero temperatures?

Key technologies include:

- Dock heaters with thermostatic control

- Thermal insulation and foam barriers

- Self-regulating PTC heating elements

- Wide-temperature-rated capacitors, ICs, and transformers

- Conformal coating or potting for moisture protection

These components help the dock operate between -40 °C and +85 °C, with responsive behavior that adjusts to real-time environmental feedback.

Can robots safely charge outdoors during snow or frost?

Yes—if the charging station is properly designed. Outdoor charging during snow or frost requires:

- Sealed, IP67/IP68 enclosures

- Insulated connectors and docking surfaces

- Smart logic to delay charging until batteries warm up

- Heaters and drainage to manage snowmelt

With these systems in place, robots can safely dock and charge during or after snowstorms, supporting full winter operations.

How should charging docks be installed in cold regions?

Install docks on elevated pads or mounts to avoid snow burial. Ensure they are angled or designed for runoff, with cable routing protected from ice buildup. If outdoors, the dock should be placed in sun-exposed zones when possible and include heaters or anti-ice coatings for public safety. Phihong recommends using field-ready installation kits tailored for low-temperature environments.

How does Phihong help OEMs deploy cold-weather charging systems?

Phihong USA provides:

- Wide-temp, outdoor-rated power modules

- Custom heating and insulation options for docks

- Edge-enabled charging logic with smart temperature controls

- Compliance consulting for UL/IEC/IP certifications in extreme environments

We work with robotics OEMs and deployment teams to ensure every charging system is cold-proof, field-tested, and scalable across climates.