BLOG

Why Do DC/DC Converters Overheat in Compact Designs and How Can Engineers Prevent Failure?

QUICK LINKS

Why Do DC/DC Converters Overheat in Compact Designs?

DC/DC converters in compact designs overheat because thermal constraints escalate faster than electrical limits as power density increases. OEM systems continue to shrink in size while requiring higher output power, wider input voltage ranges, and stable regulation across variable load conditions. This compression of electrical energy into a smaller physical footprint leaves less surface area and fewer paths for heat to escape.

In dense layouts, heat-generating components such as switching transistors, magnetics, rectifiers, and control circuitry operate in close proximity. Limited PCB copper, restricted airflow, and enclosure constraints make it difficult to distribute heat evenly. Even converters with high efficiency ratings can develop localized hot spots that raise semiconductor junction temperatures beyond safe limits during sustained operation.

Real-world deployment conditions further increase overheating risk. Elevated ambient temperatures, sealed or fanless enclosures, and continuous high-load operation are common in industrial and medical environments. Under these conditions, converters often reach thermal limits before electrical limits, leading to derating, shutdowns, or long-term reliability degradation if thermal behavior is not addressed early in the design process.

Top Benefits

• Improves system reliability by maintaining safe junction temperatures

• Reduces unexpected thermal shutdowns during real-world operation

• Supports consistent electrical performance in compact systems

Best Practices

• Evaluate thermal behavior using worst-case ambient temperature and continuous load

• Identify dominant loss contributors instead of relying only on efficiency ratings

• Design PCB copper areas and thermal vias to promote effective heat spreading

Helpful Tips

• Review thermal derating curves rather than only nominal power ratings

• Measure hot-spot temperatures during prototype testing inside final enclosures

• Align electrical, mechanical, and thermal teams early in the design cycle

Mini Q&A

Why do DC/DC converters overheat even with high efficiency?

High efficiency lowers total losses, but localized losses can still create concentrated hot spots in compact layouts.

Is overheating more common in sealed enclosures?

Yes, limited airflow and trapped heat significantly increase internal temperature rise.

Does overheating always cause immediate failure?

Not always, but prolonged exposure accelerates component aging and reduces reliability.

Correctly identifying overheating causes allows OEMs to design compact power systems that remain stable throughout their service life.

(Suggested Links: Internal Power Supplies | DC/DC Converters)

FEATURED PRODUCTS

AA03A-075A-R

- Output Power - 2.75W

- Output Volt - 7.5V

- Output Current - 0.366A

- Features - Fixed Blade AC Input, Limited Power Source, Class B EMI, Level VI Efficiency, Standard Barrel Connector

AC Series

- Output Current - 16A

- Features - Mode 2-chargers can use a circuit ranging from 8Amp to 16Amp with a local standard AC input plug installed for operation, Provides overcurrent, over voltage and short circuit protection, Protected against strong jets of water from all directions, Continuously monitors/supervises the ground connection between the AC supply and EV to ensure safe and reliable charging

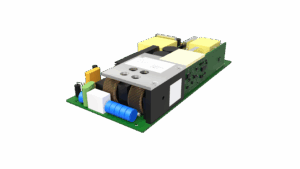

BF550-234A-R

- Output Power - 550W

- Output Volt - 12Vdc / 54.5Vdc

- Features - Universal AC Input range, Class I Design , Class B EMI , High Efficiency Performance , OVP, OCP, SCP, OTP Protections , Operating Altitude: 5,000M

DA1000Z-240AEV-R

- Output Power - 1000W

- Output Volt - 24V

- Output Current - 1000W

- Features - Extended operating temperature range of -40℃ to 70℃, Fan-less aluminum case filled with heat conductive glue, Able to withstand 10G vibration, Power on LED indicator, Short Circuit, Over Current, Over Voltage, and Over Temperature Protections, & Adjustable output through potentiomete

DA60U-240A-R

- Output Power - 60W

- Output Volt - 24V

- Output Current - 2.5A

- # of ports - 1

- Features - RESNA Compliant, CEC Compliant, LED Indicators Charge State, OVP, OTP, SCP, Charges AGM Batteries, Max 12hrs Charging Time

DA200U-250A-R

- Output Power - 200W

- Output Volt - 24V

- Output Current - 8A

- # of ports - 1

- Features - RESNA Compliant, CEC Compliant, LED Indicators Charge State, OVP, OTP, SCP, Dual-Mode Charger, Charges GEL or AGM batteries, Max 12hrs Charging Time

How Does Increasing Power Density Create Thermal Stress in DC/DC Converters?

Increasing power density creates thermal stress by forcing more electrical energy through smaller physical volumes. As converters deliver higher wattage from reduced footprints, the thermal path from internal heat sources to ambient air becomes constrained. This makes temperature rise more sensitive to even small increases in electrical loss.

Design approaches used to reduce size often introduce additional heat. Higher switching frequencies reduce magnetics size but increase switching and core losses. Smaller packages limit surface area for heat dissipation, while dense layouts cause thermal coupling between adjacent components. These effects combine to elevate internal temperatures faster than expected.

Power density also influences derating behavior. Many converters are rated assuming ideal cooling conditions that do not reflect real installations. When operated near rated output for extended periods, compact converters may be forced to reduce output power or efficiency to remain within safe thermal limits, impacting system-level performance if not anticipated.

Top Benefits

• Balances size reduction with predictable thermal performance

• Improves long-term stability in high-density power designs

• Reduces unexpected derating during sustained operation

Best Practices

• Review efficiency and loss curves across temperature and load ranges

• Evaluate switching frequency tradeoffs alongside thermal impact

• Build thermal margin into power budgets for continuous operation

Helpful Tips

• Avoid designing to maximum rated power without derating analysis

• Model thermal interaction between adjacent heat sources

• Validate thermal assumptions with enclosure-level testing

Mini Q&A

What is power density in DC/DC converters?

Power density measures how much power is delivered per unit volume, typically expressed in watts per cubic inch.

Why does higher power density increase overheating risk?

More heat is generated in less space, limiting the ability to dissipate it effectively.

Can derating fully resolve thermal stress?

Derating helps, but it must be planned early to avoid system performance gaps.

Managing power density intentionally helps OEMs align compact form factors with realistic thermal expectations.

(Suggested Links: DC/DC Modules | Industrial Power Supplies)

How Do PCB Layout and Enclosure Constraints Contribute to Overheating?

PCB layout and enclosure design strongly influence whether heat can escape from a compact DC/DC converter. Limited copper area, insufficient thermal vias, and dense component placement reduce the effectiveness of heat spreading through the board. Even well-designed converters can overheat if surrounding layout decisions restrict thermal flow.

Enclosure constraints introduce additional challenges. Sealed housings limit convection, while shielding and structural materials may trap heat rather than conduct it away. Converters placed near enclosure walls or adjacent to other heat-generating subsystems experience elevated local temperatures that are difficult to predict without system-level testing.

Mechanical and layout decisions are often finalized early in development. Once PCB stackups and enclosure geometry are locked, thermal mitigation options become limited and costly. Addressing layout and enclosure considerations early helps prevent redesigns and improves long-term reliability.

Top Benefits

• Improves thermal performance without increasing converter size

• Reduces late-stage redesigns caused by thermal failures

• Supports predictable behavior in final installations

Best Practices

• Use thermal planes and vias to move heat away from power components

• Avoid clustering multiple heat sources in confined board regions

• Validate thermal behavior inside final enclosures

Helpful Tips

• Coordinate electrical and mechanical teams early in development

• Test converters in final housings rather than open fixtures

• Monitor both component and ambient temperatures during validation

Mini Q&A

Can PCB layout alone cause DC/DC overheating?

Yes, insufficient copper and poor heat spreading can raise temperatures beyond safe limits.

Do metal enclosures always improve cooling?

Not necessarily, as some enclosures trap heat when airflow is limited.

When should enclosure thermal testing occur?

As early as possible, before mechanical constraints are locked.

Early coordination between layout and enclosure design reduces thermal risk and improves deployment reliability.

(Suggested Links: Open-Frame Power Supplies)

CLIENT'S QUOTE

Phihong stood out because they understood our needs as an OEM. From PoE solutions to power adapters, everything integrated smoothly, required less hands-on maintenance, and helped us bring products to market faster while keeping costs under control.

Compact DC/DC Converter Designs Demand Early Thermal Tradeoff Decisions

Compact DC/DC converter designs force engineers to make thermal tradeoff decisions much earlier in the development process. As systems become smaller, there is less tolerance for correcting thermal issues late in the cycle. Choices related to topology, switching frequency, package style, and power rating all influence heat generation and dissipation, and these decisions often cascade into layout and enclosure constraints.

Thermal tradeoffs are rarely isolated. Increasing efficiency may reduce total losses but can introduce localized heating in switching devices. Reducing component size may save board space but limit surface area for heat transfer. Selecting higher power ratings without adequate cooling paths can push converters into derating under real operating conditions. These interactions make early thermal awareness critical for reliable system design.

When thermal considerations are deferred, mitigation options become limited. Adding airflow, heat sinks, or mechanical changes late in development increases cost and risk. OEMs that evaluate thermal behavior alongside electrical performance early are better positioned to deliver compact systems that perform reliably across real-world environments.

Top Benefits

• Reduces late-stage redesigns driven by thermal failures

• Improves predictability of performance under sustained load

• Supports long-term reliability in compact system architectures

Best Practices

• Evaluate topology and switching frequency with thermal impact in mind

• Review thermal limits alongside electrical ratings during component selection

• Reserve PCB and mechanical margin for heat dissipation early

Helpful Tips

• Treat thermal headroom as a design requirement, not an afterthought

• Document thermal assumptions alongside electrical specifications

• Validate early prototypes under worst-case thermal conditions

Mini Q&A

Why are early thermal decisions so important in compact designs?

Because once layout and enclosure constraints are fixed, thermal mitigation options become limited and costly.

Can thermal tradeoffs affect efficiency goals?

Yes, optimizing for size or efficiency alone can unintentionally increase localized heating.

Is early thermal analysis worth the added effort?

Yes, it reduces downstream risk and improves overall system reliability.

Making thermal tradeoffs early helps OEMs avoid hidden constraints that surface late in deployment.

(Suggested Links: DC/DC Modules | Open-Frame Power Supplies)

Thermal Derating Is a System-Level Behavior, Not a Component Issue

Thermal derating in DC/DC converters is often misunderstood as a component limitation rather than a system-level behavior. While converters include internal protection mechanisms, derating is influenced heavily by surrounding layout, enclosure design, airflow, and adjacent heat sources. Treating derating as an isolated converter issue can lead to unrealistic system expectations.

In compact systems, converters frequently operate near their thermal thresholds during sustained load. As internal temperatures rise, output power may be reduced automatically to protect components. If system power budgets do not account for this behavior, downstream subsystems may experience voltage instability or performance degradation during peak operation.

Understanding derating behavior requires testing under real operating conditions. Ambient temperature, airflow restriction, and enclosure materials all affect when and how derating occurs. OEMs that model and validate derating at the system level can design around it rather than react to it after deployment.

Top Benefits

• Prevents unexpected power reduction during normal operation

• Improves system stability under thermal stress

• Aligns power budgeting with real operating conditions

Best Practices

• Review converter derating curves in the context of enclosure conditions

• Test sustained full-load operation at elevated ambient temperatures

• Budget power with derating margins included

Helpful Tips

• Avoid sizing converters exactly at peak load without margin

• Validate derating behavior during system integration testing

• Communicate derating assumptions across engineering teams

Mini Q&A

Is thermal derating a sign of poor converter design?

No, derating is a protective behavior that prevents damage under high temperature conditions.

Can derating be eliminated entirely?

Not realistically, but it can be managed with proper design and margin planning.

Should derating be tested at the board level or system level?

System-level testing provides the most accurate representation of real behavior.

Designing with derating in mind ensures stable power delivery across real-world operating scenarios.

(Suggested Links: Industrial Power Supplies | Enclosed Power Supplies)

Preventing Overheating Requires Coordinated Electrical, Mechanical, and Thermal Design

Preventing overheating in compact DC/DC converter designs requires coordination across electrical, mechanical, and thermal disciplines. Electrical efficiency alone does not guarantee safe thermal operation if mechanical constraints restrict airflow or layout decisions trap heat. Successful designs consider thermal behavior as an integrated system characteristic.

Electrical engineers focus on topology, switching behavior, and component selection, while mechanical teams define enclosure geometry, materials, and airflow paths. Thermal performance emerges from the interaction of these decisions. When teams work in isolation, thermal issues often surface late, requiring compromises that impact cost or performance.

Early cross-disciplinary collaboration enables practical mitigation strategies. Adjusting component placement, improving heat spreading paths, or modifying enclosure features early in the cycle is far more effective than late-stage fixes. OEMs that adopt this integrated approach achieve higher reliability without increasing system complexity.

Top Benefits

• Reduces thermal risk through coordinated design decisions

• Improves efficiency of mitigation strategies

• Supports scalable and repeatable compact system designs

Best Practices

• Align electrical and mechanical requirements during early design reviews

• Validate thermal assumptions across disciplines

• Treat thermal performance as a shared responsibility

Helpful Tips

• Include thermal checkpoints in design milestones

• Share thermal test results across teams

• Revisit assumptions when system constraints change

Mini Q&A

Why is cross-team coordination critical for thermal performance?

Because thermal behavior results from combined electrical, mechanical, and environmental factors.

Can electrical optimization alone prevent overheating?

No, without mechanical and thermal alignment, electrical gains may not translate to safe temperatures.

When should cross-disciplinary thermal reviews occur?

Early and repeatedly throughout development, not just before release.

Integrated design coordination is essential for preventing overheating in compact DC/DC converter systems.

(Suggested Links: Internal Power Supplies | DC/DC Converters)

How Phihong Supports Reliable Thermal Performance in Compact DC/DC Converter Designs

Managing heat in compact DC/DC converter designs requires more than component selection. It demands manufacturing discipline, validated thermal behavior, and consistency across real-world operating conditions. Phihong supports OEMs by designing DC/DC power solutions that balance power density, efficiency, and thermal stability from the outset.

Phihong’s engineering approach emphasizes realistic thermal assumptions rather than idealized lab conditions. Converter designs are evaluated under elevated ambient temperatures, sustained load scenarios, and enclosure-constrained environments to ensure predictable behavior after deployment. This reduces the risk of unexpected derating, shutdowns, or long-term reliability issues once systems are installed in the field.

As a global manufacturer, Phihong also supports compliance and documentation requirements that matter to OEMs shipping products internationally. Thermal behavior is validated alongside electrical performance to ensure converters meet safety, efficiency, and reliability expectations across industrial and medical applications. This system-level perspective helps OEMs design compact power architectures with confidence and long-term scalability.

(Suggested Links: DC/DC Converters | Internal Power Supplies)

FEATURED RESOURCE

Phihong's Power-Over-Ethernet solutions have transformed our network, boosting efficiency and reducing costs.

FAQ

Why do DC/DC converters overheat more often in compact systems?

DC/DC converters overheat more often in compact systems because heat is generated in a much smaller physical space with fewer paths for dissipation. As power density increases, switching devices, magnetics, and rectifiers operate closer together, creating localized hot spots. These hot spots can push junction temperatures beyond safe limits even when overall efficiency appears high.

Real-world conditions amplify the issue. Elevated ambient temperatures, sealed or fanless enclosures, and sustained high-load operation reduce thermal margin further. Without early thermal planning, compact systems may reach thermal limits before electrical limits, leading to derating, shutdowns, or long-term reliability degradation.

How does thermal derating impact overall system performance?

Thermal derating limits output power or efficiency to protect the converter when internal temperatures exceed safe thresholds. While derating prevents immediate damage, it can reduce available power during peak demand, affecting downstream subsystems. If power budgets are built without accounting for derating behavior, systems may experience voltage instability or reduced functionality.

Understanding derating as a system-level behavior allows engineers to plan appropriate thermal and power margins. Designing with derating in mind helps maintain predictable performance under real operating conditions rather than ideal lab scenarios.

Can PCB layout alone cause DC/DC converter overheating?

Yes, PCB layout alone can significantly contribute to overheating. Limited copper area, insufficient thermal vias, and dense component placement restrict heat spreading through the board. Even a well-designed converter can overheat if surrounding layout decisions trap heat or prevent efficient thermal flow.

Proper layout planning is especially critical in compact systems. Coordinating layout decisions with enclosure design and validating thermal behavior at the system level helps prevent overheating that might not appear during early bench testing.

Is high efficiency enough to prevent overheating in compact designs?

High efficiency reduces total losses, but it does not guarantee safe thermal performance. Localized losses can still create concentrated hot spots that exceed junction temperature limits. Thermal behavior depends on how heat is distributed and removed, not just how much heat is generated.

Engineers must evaluate efficiency alongside layout, enclosure constraints, airflow, and operating profiles. A balanced approach ensures compact designs remain thermally stable across real-world conditions.

When should thermal testing be performed during development?

Thermal testing should begin early and continue throughout development. Early testing validates design assumptions, while later testing confirms behavior in final enclosures and operating environments. Waiting until late stages often limits mitigation options and increases redesign risk.

Repeated thermal validation helps engineers identify issues before deployment, improving long-term reliability and reducing costly field failures.