BLOG

Best Guide to Next-Generation Robot Power Supplies: GaN, USB-C, Wireless, and Ruggedized Solutions

Table of contents

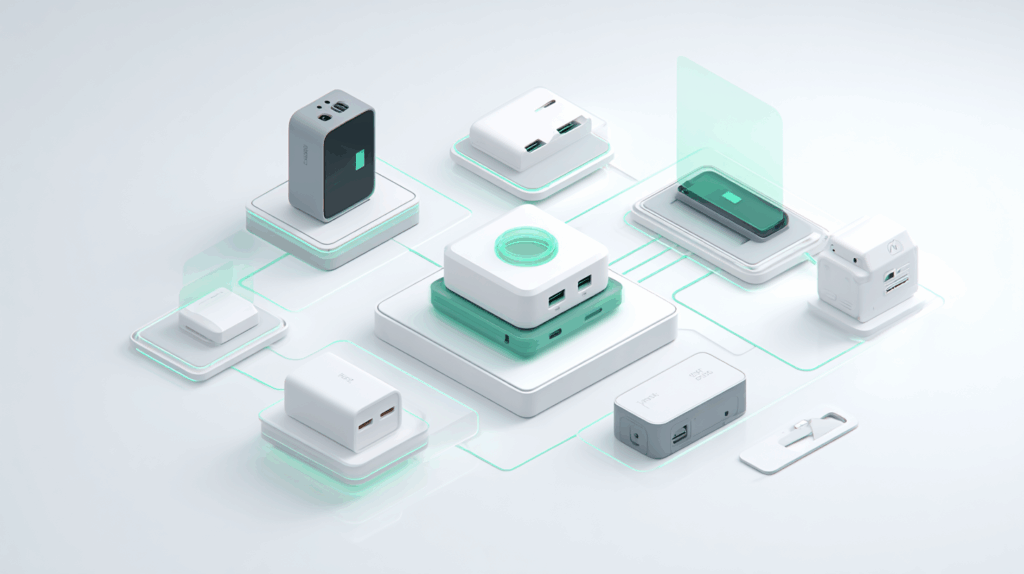

Robotic systems are evolving faster than ever, and so are the technologies that keep them powered. From warehouses to battlefields, robots now operate in environments that demand compact, efficient, and reliable energy solutions. The shift from legacy power adapters and bulky batteries to next-generation power supplies is not just a trend — it’s a necessary evolution that determines whether fleets succeed or fail in real-world deployments.

One of the most significant changes driving this transformation is the adoption of Gallium Nitride (GaN) semiconductors, USB-C PD 3.1/3.2 standards, wireless inductive charging systems, and ruggedized power supplies that can withstand extreme heat, vibration, and moisture. Together, these innovations are reshaping how robots recharge, how long they last in the field, and how safely they can operate in harsh or unpredictable environments.

For manufacturers, the choice of power supply technology is more than a technical decision — it directly impacts scalability, uptime, and compliance. GaN power supplies, for example, enable smaller and lighter chargers with higher efficiency, which is critical for mobile robots with strict space and weight limits. USB-C PD delivers universality, allowing a single port and cable type to serve multiple devices across fleets. Wireless charging removes mechanical wear while enabling robots to charge in motion or in contaminated spaces. Ruggedized solutions ensure charging reliability in environments ranging from frozen fields to military bases.

This guide explores the technologies, standards, and design strategies shaping next-generation robot power supplies. We’ll look at how GaN, USB-C, wireless, swappable battery systems, universal docks, ruggedized designs, and defense-grade power systems are redefining performance. By the end, you’ll understand how OEMs, operators, and engineers can leverage these innovations to improve reliability, scalability, and efficiency in robotic fleets.

How Gallium Nitride (GaN) Is Powering the Next Generation of Compact, High-Efficiency Robot Power Supplies

Gallium Nitride, or GaN, is one of the most important semiconductor breakthroughs in modern power design. Unlike traditional silicon, GaN supports higher switching frequencies and greater energy efficiency, enabling chargers that are smaller, lighter, and cooler-running than their silicon counterparts. For robots where every gram and cubic inch counts, GaN is unlocking new design possibilities.

Why Is GaN Transforming Robot Power Architecture?

GaN enables higher power density, meaning more watts can be delivered in smaller packages. Robots that once required bulky adapters can now carry compact chargers that free up space for sensors, AI processors, or larger batteries. This makes GaN especially valuable for autonomous mobile robots (AMRs), drones, and service robots where mobility and efficiency are priorities.

How Does GaN Improve Efficiency and Thermal Management?

By reducing switching losses and heat generation, GaN minimizes wasted energy. Cooler operation extends component lifespan and reduces the need for bulky heat sinks. This is critical for robots operating in sealed enclosures or dusty environments where airflow is limited.

What Industries Benefit Most from GaN Power Supplies?

From logistics robots in warehouses to defense drones in the field, GaN supports applications that require lightweight, compact, and efficient power. Medical robots also benefit, as GaN enables silent, cooler systems with high reliability in sensitive environments.

Top Features

-

Higher power density in smaller footprints

-

Greater efficiency with lower heat output

-

Compact, lightweight designs ideal for mobile robots

Top Benefits

-

Extended battery life through efficient energy conversion

-

More space for sensors and mission-critical hardware

-

Reduced cooling requirements and longer component life

Best Practices

-

Adopt GaN in mobile robots where weight and size are critical

-

Use GaN to reduce thermal stress in sealed enclosures

-

Partner with suppliers experienced in GaN packaging and compliance

Related Links

How Gallium Nitride (GaN) Is Powering the Next Generation of Compact, High-Efficiency Robot Power Supplies

Building Resilient Power Supplies for Extreme Environments: IP68, Wide Temp, and Vibration-Tolerant Designs

FAQ

Q: What makes GaN better than silicon for robot power supplies?

A: GaN is more efficient, runs cooler, and allows higher power density, which leads to smaller and lighter chargers.

Q: Are GaN chargers more expensive?

A: Initially yes, but costs are dropping as adoption grows, and long-term savings come from efficiency and durability.

Q: Can GaN handle rugged environments?

A: Yes, with proper packaging, GaN power supplies can withstand vibration, temperature extremes, and dust exposure.

By enabling compact, efficient, and rugged-ready designs, GaN is powering the next generation of robotic systems with reliability and performance.

How USB-C PD 3.1 and 3.2 Are Reshaping the Power Architecture of Modular Robotics and Edge Devices

USB-C Power Delivery (PD) has already transformed consumer electronics, but its impact on robotics is just beginning. With the introduction of USB-C PD 3.1 and 3.2 standards, robots can now draw higher power levels over universal connectors, eliminating the need for proprietary adapters. This creates enormous benefits for modular robotics and edge devices, where interoperability and scalability are key.

Why Is USB-C Becoming the Standard for Robotic Power?

USB-C offers universality — one port type can deliver both power and data. For modular robots that swap components or sensors, this flexibility reduces complexity and cost. Instead of managing multiple power formats, engineers can standardize on USB-C, simplifying supply chains and enabling easier field maintenance.

How Do PD 3.1 and 3.2 Change the Game for High-Power Robots?

PD 3.1 and 3.2 introduce support for up to 240W of power, making USB-C capable of charging larger robots, industrial devices, and even displays or edge AI processors. This allows robotics fleets to scale while using a common, widely supported connector. Robots designed around USB-C can charge from a variety of sources — docks, portable packs, or grid-integrated hubs.

What Role Does USB-C Play in Modular and Edge Robotics?

Modular robots rely on flexible connections to add or remove functionality. USB-C PD delivers both power and communication through a single port, enabling hot-swappable modules and faster reconfiguration. Edge robotics also benefit because standardized USB-C hubs simplify integration with IoT devices, sensors, and AI processors deployed in the field.

Top Features

-

Universal connector for power and data

-

PD 3.1/3.2 supports up to 240W delivery

-

Hot-swappable, modular architecture

Top Benefits

-

Simplifies robotic design and integration

-

Reduces reliance on proprietary charging adapters

-

Enables modularity and scalability across fleets

Best Practices

-

Standardize on USB-C PD 3.1/3.2 for all new robot designs

-

Ensure backward compatibility with lower-power USB-C devices

-

Use certified USB-C cables and connectors to ensure safety

Related Links

How USB-C PD 3.1 and 3.2 Are Reshaping the Power Architecture of Modular Robotics and Edge Devices

What Is the Best Universal Charging Station for Multi-Environment Robots?

Swappable Battery vs. Autonomous Docking: What Leading OEMs Are Choosing for Next-Gen Mobile Robots

FAQ

Q: Can USB-C PD power large robots?

A: Yes, with PD 3.1 and 3.2, USB-C supports up to 240W, enough for many industrial and mobile robots.

Q: Why is USB-C better than proprietary adapters?

A: It reduces costs, simplifies supply chains, and enables interoperability across devices.

Q: Is USB-C rugged enough for outdoor robots?

A: With reinforced connectors and ruggedized housings, USB-C can meet industrial and field requirements.

By delivering high power and universal compatibility, USB-C PD 3.1 and 3.2 are redefining how modular robotics and edge devices stay connected and operational.

CLIENT'S QUOTE

"Phihong’s PoE solutions have made a huge difference for us! Our network runs more efficiently, and we’ve seen real cost savings. We couldn’t be happier!"

The Future of Contactless Robot Charging: Wireless and Inductive Solutions for Dusty, Wet, or Mobile Environments

Mechanical charging connectors have limitations — they wear over time, attract dust, and fail in wet or corrosive environments. For robots that operate in factories, warehouses, hospitals, or outdoors, wireless and inductive charging offers a cleaner, more reliable solution. By removing physical contact points, wireless charging ensures uninterrupted operation even in environments where dust, liquids, or frequent docking cycles would normally cause failures.

How Does Wireless Charging Improve Reliability in Harsh Conditions?

Without exposed pins or connectors, wireless charging systems eliminate the risk of corrosion or dirt buildup. Robots can recharge safely in wet or contaminated areas, from agricultural fields to hospital cleaning stations. This makes inductive charging particularly valuable for fleets that operate in environments where hygiene, weather resistance, or ruggedness is critical.

Why Are Mobile Fleets Embracing Contactless Solutions?

Mobile robots often dock multiple times a day. Mechanical connectors wear out quickly under this frequency, leading to failures and higher maintenance costs. Wireless charging solves this by using inductive pads or resonant systems that require no direct contact. Robots simply park over a charging pad or move through an embedded wireless field, enabling continuous operation with minimal downtime.

What Applications Benefit Most from Wireless Charging?

Warehouse AGVs, delivery robots, hospital cleaning machines, and agricultural bots are among the leading adopters. In these sectors, reducing downtime and avoiding connector wear translate directly into lower costs and longer robot lifespans. Wireless charging also supports autonomous fleets by reducing the need for human intervention in docking.

Top Features

-

Inductive and resonant charging without physical connectors

-

Dust- and water-resistant designs for harsh environments

-

Alignment systems for precise autonomous docking

Top Benefits

-

Reduced maintenance costs from fewer mechanical failures

-

Reliable charging in contaminated or wet conditions

-

Seamless integration with autonomous fleets

Best Practices

-

Deploy wireless charging in environments with high dust or moisture

-

Pair inductive charging with AI-based alignment for accuracy

-

Use ruggedized pads or embedded floor systems for industrial settings

Related Links

The Future of Contactless Robot Charging: Wireless and Inductive Solutions for Dusty, Wet, or Mobile Environments

Building Resilient Power Supplies for Extreme Environments: IP68, Wide Temp, and Vibration-Tolerant Designs

Swappable Battery vs. Autonomous Docking: What Leading OEMs Are Choosing for Next-Gen Mobile Robots

FAQ

Q: How does wireless charging work for robots?

A: Inductive pads or resonant systems transfer energy without physical connectors, reducing wear and contamination risks.

Q: Is wireless charging slower than wired charging?

A: Historically yes, but modern inductive systems now deliver high power levels comparable to traditional docks.

Q: Can wireless charging work outdoors?

A: Yes, ruggedized inductive systems are designed for wet, dusty, or mobile environments like farms or city streets.

By eliminating connectors and enabling safe recharging in any environment, wireless and inductive solutions are paving the way for resilient, next-generation robotic fleets.

Swappable Battery vs. Autonomous Docking: What Leading OEMs Are Choosing for Next-Gen Mobile Robots

As fleets of mobile robots expand, one of the most debated design decisions is whether to use swappable battery packs or autonomous docking stations. Both approaches aim to maximize uptime and reduce downtime, but each comes with trade-offs in cost, complexity, and operational workflow. Leading OEMs are making different choices depending on their industry, deployment scale, and performance priorities.

Why Are Some Manufacturers Choosing Swappable Batteries?

Swappable batteries allow robots to resume operation almost instantly. Instead of waiting for a dock charge cycle, operators can remove a depleted pack and replace it with a charged one. This is particularly valuable in industries like logistics, where uptime is critical and robots cannot afford to sit idle. It also gives operators flexibility to recharge batteries separately while robots continue working.

What Are the Advantages of Autonomous Docking?

Autonomous docking removes the need for human intervention. Robots align with charging stations automatically, ensuring consistent recharging cycles. This approach reduces labor costs and integrates seamlessly with predictive AI systems that schedule charging when demand is low. It is particularly effective for fleets deployed in hospitals, airports, or city streets where 24/7 operation is expected.

Which Approach Is Winning in Real Deployments?

OEMs are taking a hybrid approach. Logistics and warehouse robots often use swappable batteries to maximize throughput, while delivery robots, cleaning machines, and security bots favor autonomous docking for convenience and labor savings. The decision often comes down to whether uptime or autonomy is the top priority.

Top Features

-

Swappable packs for instant turnaround

-

Auto-docking systems for hands-free charging

-

Hybrid models offering both approaches

Top Benefits

-

Flexible deployment strategies for different industries

-

Reduced downtime through instant swaps or automated charging

-

Optimized maintenance and battery lifecycle management

Best Practices

-

Use swappable batteries for fleets with intense duty cycles

-

Deploy auto-docking in public-facing or service-oriented fleets

-

Consider hybrid solutions for maximum flexibility

Related Links

The Future of Contactless Robot Charging: Wireless and Inductive Solutions for Dusty, Wet, or Mobile Environments

What Is the Best Universal Charging Station for Multi-Environment Robots?

FAQ

Q: Why do some fleets prefer swappable batteries?

A: Swapping minimizes downtime and allows continuous operation without waiting for a charge.

Q: Is autonomous docking more efficient overall?

A: For many fleets, yes — especially when integrated with AI scheduling and predictive maintenance.

Q: Can a single fleet use both systems?

A: Yes, hybrid designs are emerging to combine the flexibility of swappable packs with the autonomy of docking.

By balancing the benefits of swappable batteries and autonomous docking, OEMs are tailoring power strategies that keep robots mission-ready around the clock.

What Is the Best Universal Charging Station for Multi-Environment Robots?

As robots are deployed across warehouses, streets, farms, and hospitals, operators are seeking universal charging stations capable of supporting multiple environments and robot types. A universal dock not only simplifies infrastructure but also reduces costs by replacing the need for specialized chargers for each fleet segment.

Why Is a Universal Docking Approach Important?

In multi-environment deployments, operators often manage mixed fleets of delivery robots, AGVs, drones, and service machines. Without universal charging, each fleet requires its own infrastructure, driving up complexity and cost. Universal docks streamline this by offering standardized connectors, flexible power outputs, and ruggedized housings suitable for both indoor and outdoor use.

How Do Universal Stations Improve Scalability?

By adopting common standards such as USB-C PD, modular connectors, or wireless pads, universal stations can charge multiple robot types. This allows operators to scale fleets quickly without investing in new infrastructure. It also simplifies maintenance, as fewer dock models need to be stocked and serviced.

What Are the Design Challenges for Universal Charging?

The challenge lies in balancing ruggedness with flexibility. A universal dock must withstand dust, water, and vibration in outdoor environments while remaining compatible with lightweight service robots indoors. Advanced designs now include smart adapters and AI-based recognition systems that identify robot type and adjust charging protocols automatically.

Top Features

-

Support for multiple power formats (USB-C, inductive, modular)

-

Rugged housings for outdoor reliability

-

AI-based detection for optimized charging protocols

Top Benefits

-

Lower infrastructure costs through standardization

-

Simplified maintenance across mixed fleets

-

Greater scalability for operators deploying diverse robots

Best Practices

-

Standardize fleets around common connector types

-

Invest in universal docks for long-term scalability

-

Choose ruggedized models for fleets operating indoors and outdoors

Related Links

How USB-C PD 3.1 and 3.2 Are Reshaping the Power Architecture of Modular Robotics

Building Resilient Power Supplies for Extreme Environments: IP68, Wide Temp, and Vibration-Tolerant Designs

FAQ

Q: Can a universal charging station support both indoor and outdoor robots?

A: Yes, ruggedized designs with smart adapters can serve mixed fleets across multiple environments.

Q: Do universal stations cost more than specialized docks?

A: They may cost more upfront, but they reduce infrastructure and maintenance costs long term.

Q: Are universal docks common today?

A: Adoption is growing as operators demand standardization and scalability across fleets.

With universal charging stations, operators can simplify infrastructure and scale diverse fleets efficiently across every environment.

Building Resilient Power Supplies for Extreme Environments: IP68, Wide Temp, and Vibration-Tolerant Designs

Robots are increasingly deployed in places where traditional electronics fail — frozen warehouses, desert construction sites, offshore platforms, or mining tunnels. To survive in these environments, charging stations and power supplies must be engineered for IP68 water and dust protection, wide temperature operation, and tolerance against constant vibration and shock.

Why Is IP68 Protection Essential?

IP68-rated power supplies are fully dust-tight and can withstand long-term water immersion. For agricultural robots operating in wet fields or marine robots deployed at seaports, IP68 ensures reliable power transfer without short circuits, corrosion, or downtime caused by environmental stress.

How Do Wide-Temperature Designs Support Harsh Environments?

Standard chargers fail when exposed to extreme cold or heat. Wide-temperature supplies — rated from -40 °C to +70 °C — ensure robots can operate in freezing storage facilities, desert climates, or high-heat industrial zones. This allows fleets to remain mission-ready regardless of seasonal or geographic extremes.

What Role Does Vibration Tolerance Play?

For defense, mining, or heavy industrial robots, vibration and shock are unavoidable. Ruggedized supplies use reinforced housings, shock-absorbing mounts, and resilient connectors to prevent internal damage. This durability ensures reliable operation even under constant mechanical stress.

Top Features

-

IP68 protection against water and dust

-

Wide operating temperature range (-40 °C to +70 °C)

-

Reinforced housings for vibration resistance

Top Benefits

-

Reliable charging in extreme climates and industrial zones

-

Extended fleet deployment in challenging outdoor conditions

-

Lower maintenance and fewer failures over time

Best Practices

-

Specify IP68 supplies for fleets in wet or dusty environments

-

Match thermal specs to deployment regions

-

Use vibration-tolerant designs in mining, defense, or construction fleets

Related Links

The Future of Contactless Robot Charging: Wireless and Inductive Solutions for Dusty, Wet, or Mobile Environments

How Military and Defense Applications Are Shaping Ruggedized Robot Charging Stations for Harsh Field Environments

FAQ

Q: Why is IP68 preferred over IP67 in robotics?

A: IP68 provides longer and deeper water resistance, ideal for marine, agricultural, or heavy-duty outdoor use.

Q: Can ruggedized power supplies handle both heat and cold?

A: Yes, wide-temp designs keep robots operational across extreme conditions from freezing cold to desert heat.

Q: Do ruggedized supplies cost more?

A: They do initially, but long-term savings come from fewer failures and lower maintenance.

By combining IP68 sealing, wide-temp resilience, and vibration tolerance, next-gen power supplies deliver the reliability robots need to thrive in extreme environments.

How Military and Defense Applications Are Shaping Ruggedized Robot Charging Stations for Harsh Field Environments

Defense and military sectors push robotic systems to their limits, requiring power supplies that can endure extreme stress while remaining compact and portable. From field logistics robots to unmanned ground vehicles (UGVs) and drones, ruggedized charging stations for defense use cases are setting new standards for durability and reliability.

Why Does Defense Robotics Demand Ruggedized Charging?

Military robots often operate in desert heat, arctic cold, or muddy terrain where standard chargers fail. Ruggedized stations are designed to withstand exposure to sand, water, shock, and even electromagnetic interference, ensuring mission-critical robots stay powered.

How Do Military Requirements Influence Civilian Robotics?

Defense-grade requirements often set the bar for commercial applications. Features like IP68 housings, wide-temp tolerances, and hardened enclosures developed for defense robots are increasingly adopted by industrial fleets in construction, mining, and offshore industries. Military innovation drives civilian resilience.

What Technologies Are Emerging in Defense Power Systems?

Swappable battery packs, portable solar-assisted charging, and EMP-shielded supplies are gaining traction in defense deployments. These innovations enable fast, field-ready power solutions that can be redeployed quickly without heavy infrastructure. Civilian industries are beginning to adopt the same technologies for resilience in remote or disaster-response scenarios.

Top Features

-

EMP-shielded and interference-resistant designs

-

Portable, solar-assisted charging stations

-

Field-repairable ruggedized housings

Top Benefits

-

Mission-critical reliability for defense fleets

-

Technology transfer to industrial and commercial robots

-

Enhanced resilience in remote and disaster environments

Best Practices

-

Adapt defense-grade ruggedization for commercial deployments

-

Leverage modular, field-ready charging solutions

-

Ensure compliance with both military and civilian standards

Related Links

How Military and Defense Applications Are Shaping Ruggedized Robot Charging Stations for Harsh Field Environments

Building Resilient Power Supplies for Extreme Environments: IP68, Wide Temp, and Vibration-Tolerant Designs

Swappable Battery vs. Autonomous Docking: What Leading OEMs Are Choosing for Next-Gen Mobile Robots

FAQ

Q: Why do defense robots need specialized charging stations?

A: They operate in extreme and hostile conditions where commercial chargers would fail.

Q: Do military innovations influence industrial robots?

A: Yes, ruggedized features first designed for defense often become standard in commercial applications.

Q: Are defense-grade chargers portable?

A: Many are modular or solar-assisted, designed for fast deployment in the field.

By driving innovation in ruggedization and field-ready designs, defense applications are shaping the future of resilient robotic charging solutions across industries.

How Phihong Powers Next-Generation Robot Supply Innovations

Phihong continues to stand at the forefront of power innovation, delivering solutions that integrate the latest technologies — from GaN semiconductors and USB-C PD to wireless charging, swappable batteries, and ruggedized designs. For OEMs and operators, this means access to power supplies that are efficient, compact, and resilient enough for any environment.

Phihong’s GaN-based power supplies enable higher efficiency in smaller packages, giving mobile robots more room for critical sensors and AI processors. USB-C PD solutions provide the universality and modularity required for scalable fleets, while Phihong’s wireless charging systems offer safe, contactless power transfer in environments where dust, moisture, or hygiene is a concern.

For operators in extreme conditions, Phihong designs IP68-rated, wide-temp, and vibration-tolerant power supplies that ensure robots remain reliable in the harshest environments. Defense and industrial applications benefit from Phihong’s proven track record in ruggedized, compliant designs that meet global safety standards.

By blending efficiency, scalability, and rugged durability, Phihong enables manufacturers to confidently scale robotic fleets while lowering downtime and energy costs. Whether supporting logistics robots in warehouses or military UGVs in the field, Phihong’s next-generation power supply innovations are ready for the challenges of today and tomorrow.

With GaN, USB-C, wireless, and ruggedized solutions, Phihong delivers the power infrastructure that robotics innovators depend on for safe, scalable, and future-ready operations.

Contact Our Team Today!

Our dedicated sales team and international partners are prepared to support you with your latest projects and initiatives globally.

Explore More with Phihong USA

As we conclude our exploration of PoE technology, it’s evident how these innovations are streamlining power and data integration across various industries. Phihong USA stands at the forefront of this technological advancement, offering a diverse range of power solutions designed to meet the evolving needs of modern industries.

Phihong USA’s extensive product lineup includes:

- Power over Ethernet (PoE) Solutions: Delivering reliable power and data transmission over a single cable, ideal for simplifying network installations and reducing costs.

- AC/DC Adapters and Power Supplies: From compact adapters to industrial-grade power supplies, Phihong provides solutions that ensure efficiency and reliability in various applications.

- Battery Chargers: Customizable chargers for lithium-ion and lead-acid batteries, supporting a wide range of power requirements for mobility and industrial applications.

- Medical Power Supplies: Specialized power solutions designed to meet the stringent requirements of the healthcare industry, ensuring safety and reliability.

Phihong USA is committed to innovation and excellence, continually developing products that meet the highest standards of performance and reliability. Their global reach and dedication to customer support make them a trusted partner in powering the future.

Here are some useful links to explore Phihong USA’s offerings further and bring in new potential clients:

Visit Phihong USA to discover how their advanced power solutions can support your business needs. Whether you’re looking to upgrade your network, or find reliable power supplies, Phihong USA has you covered.

By choosing Phihong USA, you’re partnering with a leader in power technology, ensuring your operations run smoothly and efficiently with top-tier power solutions. Contact Us today!

FAQ

NEWSLETTER

Power Up Your Inbox: Get Exclusive Industry Insights, Innovations & B2B Updates from Phihong USA!