BLOG

Best Guide to TAA Compliance for Power Supply and PoE Manufacturers

QUICK LINKS

What Is TAA Compliance and Why Does It Matter in Power Electronics?

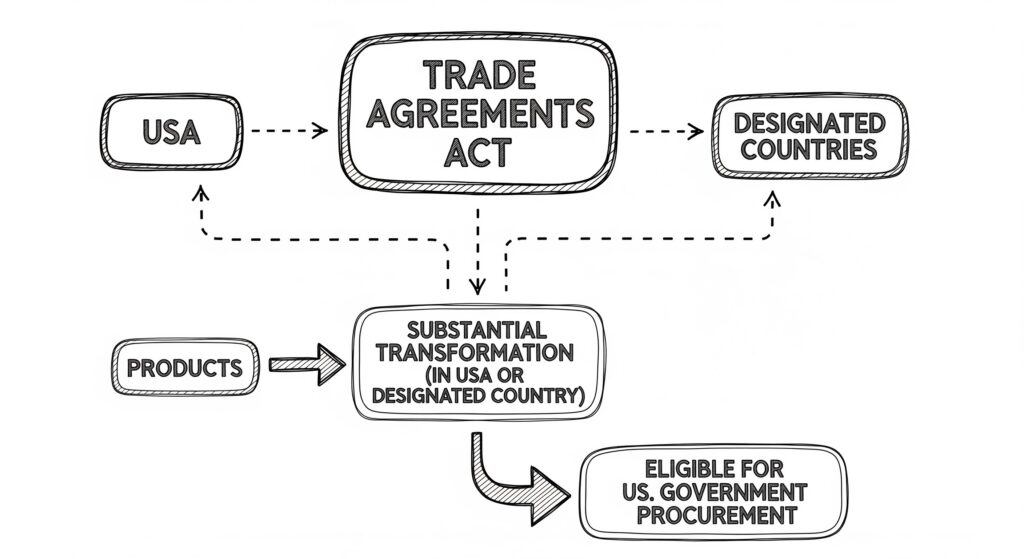

The Trade Agreements Act establishes sourcing requirements for certain U.S. government procurements. Under TAA, products must be manufactured or substantially transformed in the United States or in a designated country recognized under U.S. trade agreements.

For power electronics manufacturers, this becomes particularly relevant because global supply chains are standard practice. A power adapter may include semiconductors sourced from one region, PCB assembly in another country, firmware configuration in a third location, and final testing elsewhere. Despite that complexity, TAA focuses on where substantial transformation occurs, which determines the product’s country of origin.

In power infrastructure applications, compliance is often evaluated during procurement review. Federal integrators and government buyers may request origin documentation to confirm eligibility before contracts are awarded. For embedded power components such as PoE injectors and external power supplies, this review can impact entire system approvals.

As Vietnam continues to grow as a major electronics manufacturing hub and is recognized as a designated country under U.S. trade agreements, procurement teams increasingly evaluate how final assembly and transformation performed there may influence sourcing decisions.

For manufacturers with structured production capabilities in Vietnam, the conversation around TAA is less about marketing claims and more about documented manufacturing processes and supply chain transparency.

Top Features of TAA in Government Procurement

- Applies to specific federal contracts and trade agreement procurements

• Focuses on country of origin determined by substantial transformation

• Evaluated at the individual product level rather than brand level

• Often relevant in GSA-related and federally funded infrastructure projects

Top Benefits of Understanding TAA Early in the Sourcing Process

- Reduces risk of bid disqualification during procurement review

• Helps prevent delays caused by compliance documentation gaps

• Supports smoother conversations with federal integrators

• Strengthens supply chain transparency in regulated markets

Best Practices for Power Equipment Buyers Evaluating TAA

- Confirm whether the specific contract invokes TAA requirements

• Request country of origin documentation from suppliers

• Separate commercial sourcing strategies from government-focused sourcing

• Engage manufacturers early to understand production flow

Understanding how TAA applies at the beginning of a sourcing cycle helps buyers avoid costly revisions and strengthens overall procurement confidence.

How Country of Origin Is Determined for Power Supplies and PoE Equipment

Country of origin under TAA is determined by where a product undergoes substantial transformation. Substantial transformation occurs when a manufacturing process results in a new and distinct article of commerce with a different name, character, or use.

In power electronics, this determination often centers around core production steps such as PCB population, power conversion circuit integration, firmware programming, calibration, enclosure integration, and final system-level testing. Simply labeling, packaging, or performing minor assembly generally does not meet this threshold.

For example, if printed circuit boards are assembled, programmed, integrated into enclosures, and tested within a designated country such as Vietnam, that country may be considered the location of substantial transformation. However, each product must be evaluated individually based on its actual manufacturing flow.

As electronics production capacity in Vietnam expands across industrial power supplies, PoE injectors, and custom OEM power solutions, procurement teams are increasingly reviewing how final integration and testing in designated countries align with trade agreement sourcing standards.

Transparency in manufacturing documentation is essential. Buyers evaluating products such as PoE injectors or external power adapters should understand where PCB assembly occurs and where final configuration is completed. This information supports accurate country of origin determinations when contracts require it.

Top Features of Substantial Transformation in Electronics

- PCB assembly and integration that changes product functionality

• Firmware programming and system configuration

• Final electrical calibration and performance validation

• Controlled manufacturing processes within designated countries

Top Benefits of Clear Origin Determination

- Supports audit readiness for government procurement

• Improves sourcing accuracy during bid submission

• Enhances manufacturer credibility in regulated markets

• Reduces ambiguity in distributor relationships

Best Practices for Evaluating Country of Origin

- Request written manufacturing flow documentation

• Confirm final integration and testing location

• Understand how multi-country component sourcing impacts origin

• Maintain contract-specific compliance records

Clear country of origin documentation protects both buyers and manufacturers from unintended compliance risk and supports responsible sourcing decisions.

TAA vs BAA vs NDAA: Understanding the Differences for Power Manufacturers

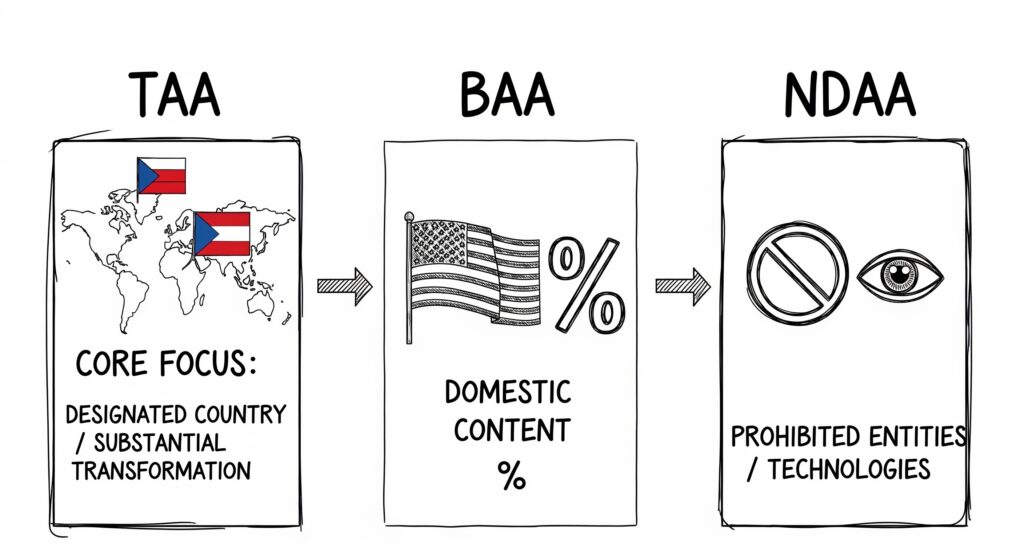

Federal sourcing regulations are often discussed together, but TAA, the Buy American Act, and NDAA restrictions each serve different regulatory purposes. Confusing these frameworks can create compliance exposure for manufacturers and procurement teams alike.

TAA focuses on whether a product is manufactured or substantially transformed in a designated country. It is frequently invoked in federal contracts connected to international trade agreements and in GSA-related procurement vehicles.

The Buy American Act emphasizes domestic content and generally prioritizes products manufactured in the United States. It often requires a defined percentage of U.S.-origin components to qualify.

NDAA restrictions focus on prohibiting certain manufacturers and technologies from specific countries in defense and sensitive infrastructure environments. These restrictions may relate to component sourcing rather than final assembly location.

For power electronics manufacturers operating globally, including facilities in Vietnam, understanding which regulation applies to a particular contract is critical. A product manufactured in a designated country such as Vietnam may satisfy TAA requirements for certain contracts but may not meet Buy American Act thresholds. Similarly, NDAA considerations may introduce separate component-level restrictions.

This distinction is particularly relevant for categories such as:

• PoE injectors used in surveillance systems

• Power adapters integrated into federal IT infrastructure

• Industrial power supplies deployed in transportation systems

Top Features of Each Regulation

• TAA evaluates designated country manufacturing and transformation

• BAA focuses on domestic content percentages

• NDAA restricts specific entities and technologies

Top Benefits of Regulatory Clarity

• Prevents mislabeling of compliance terminology

• Reduces legal and marketing risk

• Improves procurement communication accuracy

• Strengthens internal compliance processes

Best Practices for Managing Multi-Regulation Requirements

• Avoid using compliance terms interchangeably

• Confirm regulatory applicability within each contract

• Maintain separate documentation for TAA, BAA, and NDAA

• Educate sales teams on regulatory distinctions

Clear differentiation between these frameworks ensures that power manufacturers communicate responsibly while supporting procurement teams with accurate information.

CLIENT'S QUOTE

Phihong's Power-Over-Ethernet solutions have transformed our network, boosting efficiency and reducing costs. Their seamless integration has simplified both installation and maintenance.

How TAA Requirements Apply to Power Adapters, Chargers, and PoE Injectors

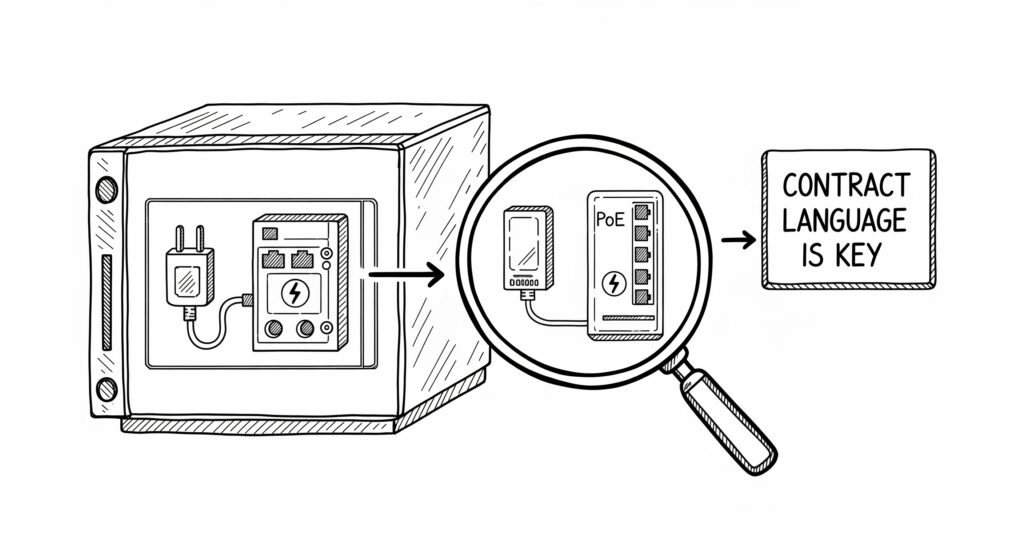

Power adapters, PoE injectors, and industrial power supplies are often considered secondary components within larger infrastructure systems. However, in government and federally funded deployments, even embedded power devices may be evaluated under sourcing regulations when contracts invoke TAA requirements.

Surveillance systems, municipal WiFi infrastructure, public safety communication networks, and transportation control systems all rely on dependable power conversion hardware. When these systems are procured under federal agreements or GSA schedules, eligibility review may extend beyond the primary equipment to include supporting components such as external adapters and PoE power injection modules.

The key factor is contract language. TAA does not automatically apply to every public project. It applies when specified in procurement documentation. That means OEM integrators must determine early in the bidding process whether power components must meet designated country sourcing standards.

For manufacturers operating in Vietnam, which is recognized as a designated country under U.S. trade agreements, the discussion often centers around where final assembly, integration, and testing occur. Procurement teams may request documentation confirming production flow and transformation location, especially for higher-volume deployments.

Because power electronics are frequently embedded within larger systems, sourcing clarity can influence overall system eligibility. This makes proactive communication between manufacturers, integrators, and procurement officers essential during early project stages.

Top Features of TAA Considerations in Power Electronics

- Applies at the individual product level

• Triggered by specific contract requirements

• Often evaluated during GSA and federal procurement review

• Requires documentation of manufacturing and transformation location

Top Benefits of Early Evaluation

- Reduces risk of system-level procurement delays

• Strengthens integrator confidence in sourcing decisions

• Helps prevent late-stage redesigns

• Supports smoother federal approval processes

Best Practices for Buyers and Integrators

- Confirm TAA applicability during bid qualification

• Request origin documentation for embedded power components

• Maintain separation between commercial and government SKUs

• Engage manufacturers early for production transparency

Proactively evaluating power equipment sourcing within the context of contract language allows organizations to manage compliance expectations responsibly while maintaining flexibility across markets.

How Buyers Can Evaluate TAA Compliance in Power Supply Sourcing

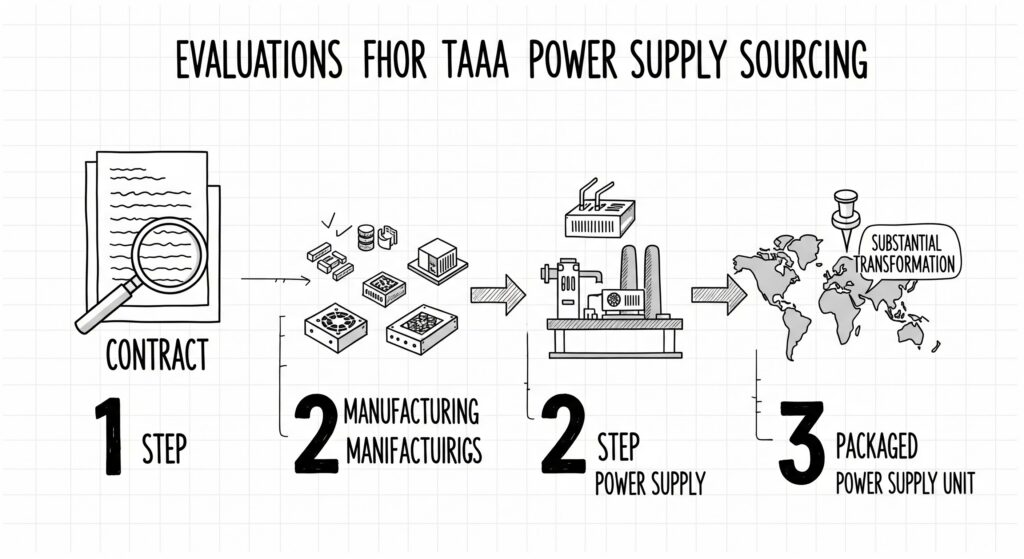

TAA compliance should be treated as a structured evaluation process rather than a label. Because global electronics manufacturing often spans multiple countries, determining country of origin requires a clear understanding of where substantial transformation occurs.

Buyers evaluating power adapters, PoE injectors, and industrial power supplies should review the manufacturing flow carefully. This includes identifying where PCB assembly is performed, where firmware is programmed, where enclosure integration takes place, and where final electrical testing is conducted. These steps collectively determine whether transformation within a designated country may establish origin.

Vietnam has become a significant manufacturing hub for power electronics, offering controlled production environments and established supply chain ecosystems. When final integration and testing are performed within designated countries such as Vietnam, procurement teams often evaluate how those processes align with contract-specific sourcing requirements.

However, TAA applicability ultimately depends on the contract. It is important to remember that TAA requirements can vary depending on the customer, contract, and project. Procurement teams should confirm eligibility requirements directly with their suppliers and internal compliance departments before making sourcing determinations.

By approaching compliance as a documented process rather than an assumption, buyers reduce exposure while maintaining sourcing flexibility.

Top Features of Responsible Compliance Evaluation

- Transparent manufacturing documentation

• Clear identification of transformation steps

• Alignment with contract language

• Separation of regulatory review from marketing claims

Top Benefits of Structured Evaluation

- Reduced audit exposure

• Increased procurement confidence

• Stronger supplier accountability

• Improved long-term sourcing strategy

Best Practices for Ongoing Compliance Management

- Request updated origin documentation periodically

• Centralize compliance records within procurement systems

• Avoid blanket assumptions about product eligibility

• Coordinate internal legal and sourcing teams as needed

Treating TAA evaluation as part of broader risk management strengthens procurement stability and supports responsible sourcing practices.

Common Misunderstandings About TAA in Electronics Manufacturing

TAA is often misunderstood within electronics procurement discussions. One of the most common misconceptions is that corporate headquarters location determines compliance. In reality, country of origin is based on where substantial transformation occurs, not where a company is incorporated or where products are marketed.

Another misunderstanding is that sourcing components from multiple countries automatically disqualifies a product. Global supply chains are common in power electronics. What matters under TAA is where the final transformation creates the finished product’s identity.

There is also confusion between TAA and other regulations such as the Buy American Act and NDAA restrictions. Each regulation addresses different procurement objectives. Misusing these terms in marketing or procurement communication can create compliance exposure.

As Vietnam continues to expand its role in electronics manufacturing, questions often arise about how designated country production influences sourcing eligibility. While manufacturing in a designated country can be relevant, eligibility must always be evaluated in relation to specific contract language and documented production processes.

Understanding these distinctions allows manufacturers and buyers to communicate clearly and avoid overstating compliance positions.

Top Features of Accurate TAA Understanding

- Country of origin is tied to transformation, not corporate address

• Multi-country component sourcing is common in electronics

• TAA differs from domestic content requirements

• Contract language determines applicability

Top Benefits of Clarified Expectations

- Prevents regulatory terminology misuse

• Reduces risk of inaccurate marketing statements

• Improves procurement communication

• Strengthens trust between suppliers and integrators

Best Practices for Reducing Misinterpretation

- Train sales and procurement teams on regulatory differences

• Avoid blanket compliance claims in marketing materials

• Confirm sourcing requirements per contract

• Maintain documented manufacturing transparency

Clear understanding of TAA reduces confusion and ensures that sourcing discussions remain grounded in documented production realities rather than assumptions.

How Phihong Supports Responsible Sourcing for Government-Focused Projects

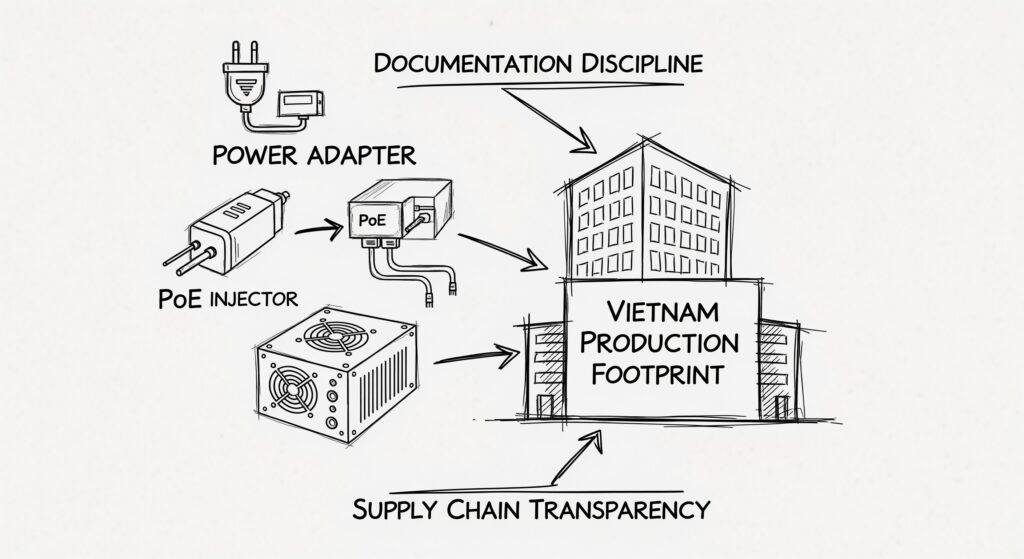

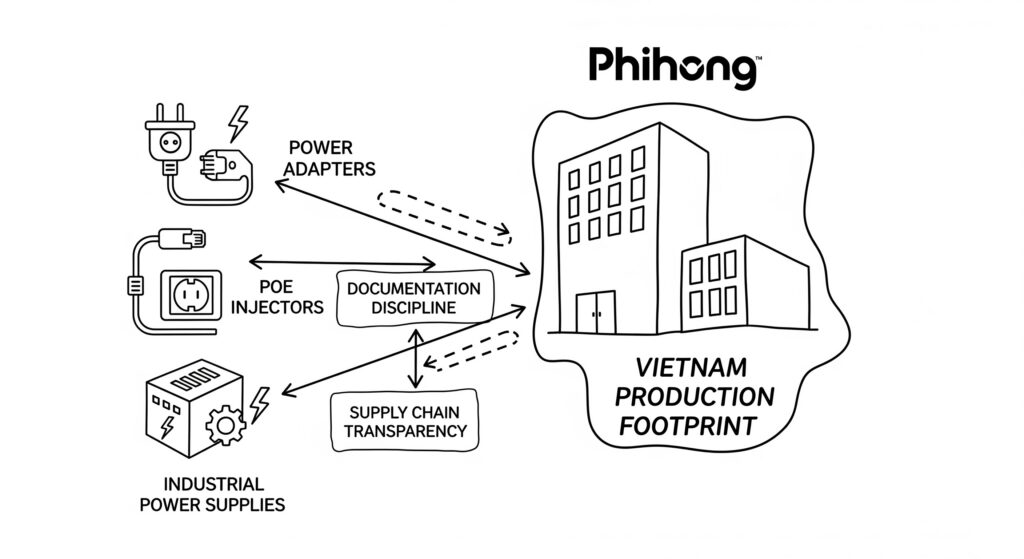

Global power electronics sourcing requires more than performance engineering. For projects influenced by federal procurement standards, manufacturers must also demonstrate structured production oversight, documentation discipline, and supply chain transparency.

Phihong operates established manufacturing capabilities in Vietnam, a country recognized under U.S. trade agreements as a designated sourcing location. This production footprint supports controlled assembly environments for power adapters, PoE injectors, and industrial power supplies. Structured PCB population, system integration, firmware configuration, and final electrical validation are conducted within defined manufacturing workflows designed to support OEM traceability standards.

While TAA eligibility ultimately depends on product-level analysis and contract-specific language, responsible sourcing begins with documented manufacturing processes. For OEM partners and integrators evaluating government-related deployments, clarity around production flow, final integration location, and quality control procedures can simplify procurement discussions.

Phihong’s focus on manufacturing consistency, production transparency, and long-term supply chain stability positions the company as a collaborative partner for organizations navigating regulated environments.

Organizations evaluating power solutions for federally influenced infrastructure projects are encouraged to consult directly with Phihong’s team to review manufacturing documentation and discuss project-specific sourcing considerations.

How Phihong Supports Responsible Sourcing for Government-Focused Projects

Global power electronics sourcing requires more than performance engineering. For projects influenced by federal procurement standards, manufacturers must also demonstrate structured production oversight, documentation discipline, and supply chain transparency.

Phihong operates established manufacturing capabilities in Vietnam, a country recognized under U.S. trade agreements as a designated sourcing location. This production footprint supports controlled assembly environments for power adapters, PoE injectors, and industrial power supplies. Structured PCB population, system integration, firmware configuration, and final electrical validation are conducted within defined manufacturing workflows designed to support OEM traceability standards.

While TAA eligibility ultimately depends on product-level analysis and contract-specific language, responsible sourcing begins with documented manufacturing processes. For OEM partners and integrators evaluating government-related deployments, clarity around production flow, final integration location, and quality control procedures can simplify procurement discussions.

Phihong’s focus on manufacturing consistency, production transparency, and long-term supply chain stability positions the company as a collaborative partner for organizations navigating regulated environments.

FEATURED RESOURCE

Phihong's Power-Over-Ethernet solutions have transformed our network, boosting efficiency and reducing costs.

FAQ

Does manufacturing in Vietnam automatically make a power supply TAA compliant?

Manufacturing in Vietnam can be relevant in TAA discussions because Vietnam is recognized as a designated country under U.S. trade agreements. However, manufacturing location alone does not automatically determine TAA compliance. The regulation focuses on where substantial transformation occurs, meaning the location where the product becomes a new and distinct article of commerce.

In power electronics, this evaluation often includes PCB assembly, firmware programming, system integration, enclosure installation, and final performance testing. Each product must be assessed individually based on its specific production flow. Additionally, TAA only applies when a particular contract invokes its requirements.

For procurement teams, the safest approach is to review documented manufacturing processes and confirm sourcing requirements within the context of the contract. Responsible evaluation reduces risk and ensures clarity before bids are submitted.

What types of power products are most commonly evaluated under TAA requirements?

TAA considerations frequently arise in power adapters, PoE injectors, industrial AC DC power supplies, and custom OEM power systems used in government infrastructure. These products are often embedded within larger deployments such as surveillance systems, public safety networks, transportation systems, and municipal IT infrastructure.

When federal funding or GSA contracts are involved, even supporting components like external adapters may be evaluated for sourcing eligibility. However, TAA applicability depends entirely on the contract language. Not all public sector projects require TAA compliance.

Procurement teams should determine whether the contract invokes trade agreement requirements and then evaluate the specific products accordingly. Reviewing manufacturing documentation and understanding where substantial transformation occurs helps ensure responsible sourcing decisions.

How is substantial transformation determined in electronics manufacturing?

Substantial transformation refers to a manufacturing process that results in a new and distinct article of commerce with a different name, character, or use. In electronics manufacturing, this determination typically centers around where functional integration occurs.

For example, assembling populated circuit boards, programming firmware, integrating power conversion modules into enclosures, and conducting final electrical testing may collectively establish transformation. Minor processes such as packaging or labeling generally do not meet this threshold.

Because global supply chains are common in power electronics, the evaluation must focus on where the final functional identity of the product is created. Procurement teams often review documented production flow to understand how manufacturing stages contribute to origin determination under specific contract requirements.

Is TAA the same as the Buy American Act for power equipment?

TAA and the Buy American Act are separate regulations that address different procurement objectives. TAA allows products manufactured or substantially transformed in designated countries to qualify under certain federal contracts. The Buy American Act generally prioritizes domestic U.S. end products and may require specific domestic content percentages.

For power equipment manufacturers operating globally, including those with facilities in Vietnam, understanding the distinction is important. A product may meet TAA criteria under a trade agreement contract but may not satisfy Buy American Act thresholds.

Because contracts specify which regulation applies, procurement teams must review sourcing requirements carefully. Misusing these terms interchangeably can create confusion and compliance exposure.

How can buyers reduce compliance risk when sourcing power electronics?

Buyers can reduce compliance risk by implementing structured evaluation procedures early in the sourcing process. This includes requesting country of origin documentation, reviewing manufacturing flow charts, and understanding where substantial transformation occurs.

It is also important to confirm whether TAA applies to the specific contract. Not all government-related projects invoke trade agreement requirements. Clarifying this during bid qualification prevents unnecessary sourcing limitations.

Engaging suppliers early and maintaining clear documentation supports smoother procurement review. Treating compliance as a documented process rather than a marketing claim strengthens long-term sourcing stability and reduces audit exposure.