BLOG

Best OEM Guide to DC/DC Converters: Designing Reliable Power for Industrial and Medical Systems

QUICK LINKS

What role do DC/DC converters play in industrial and medical power architectures?

DC/DC converters are foundational components in modern industrial and medical systems. They transform and regulate voltage levels so that sensitive electronics receive stable, predictable power regardless of fluctuations at the system input. In industrial automation, DC/DC converters support controllers, sensors, communication modules, and actuators that operate under noisy electrical conditions. In medical equipment, they enable safe, low-noise power delivery to patient monitoring devices, imaging systems, diagnostic instruments, and embedded control electronics.

OEMs rely on DC/DC converters not only for voltage conversion, but also for electrical isolation, noise suppression, and protection against transients. Industrial environments often introduce voltage spikes, ground potential differences, and electromagnetic interference from motors and switching equipment. Medical environments impose additional safety constraints where leakage current, isolation integrity, and predictable behavior are critical. A well-chosen DC/DC converter helps shield downstream circuitry from these challenges while maintaining compliance with global safety standards.

As systems become more compact and power dense, the role of DC/DC converters expands. They must deliver higher efficiency, manage thermal stress, and integrate cleanly into constrained enclosures. For OEMs, DC/DC converter selection is no longer a secondary design step. It is a system-level decision that directly affects reliability, certification success, and long-term product performance.

Top Benefits

-

Provides stable voltage regulation across variable operating conditions

-

Protects sensitive electronics from electrical noise and transients

-

Enables safe and compliant power distribution in regulated environments

Best Practices

-

Define power conversion requirements early in system architecture

-

Match converter capabilities to industrial or medical safety needs

-

Consider electrical noise and isolation requirements alongside voltage levels

Understanding the role of DC/DC converters at the system level allows OEMs to design power architectures that are resilient, compliant, and scalable across demanding applications.

FEATURED PRODUCTS

AA03A-075A-R

- Output Power - 2.75W

- Output Volt - 7.5V

- Output Current - 0.366A

- Features - Fixed Blade AC Input, Limited Power Source, Class B EMI, Level VI Efficiency, Standard Barrel Connector

AC Series

- Output Current - 16A

- Features - Mode 2-chargers can use a circuit ranging from 8Amp to 16Amp with a local standard AC input plug installed for operation, Provides overcurrent, over voltage and short circuit protection, Protected against strong jets of water from all directions, Continuously monitors/supervises the ground connection between the AC supply and EV to ensure safe and reliable charging

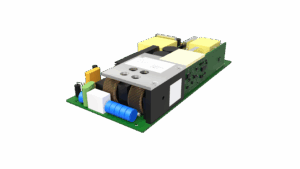

BF550-234A-R

- Output Power - 550W

- Output Volt - 12Vdc / 54.5Vdc

- Features - Universal AC Input range, Class I Design , Class B EMI , High Efficiency Performance , OVP, OCP, SCP, OTP Protections , Operating Altitude: 5,000M

DA1000Z-240AEV-R

- Output Power - 1000W

- Output Volt - 24V

- Output Current - 1000W

- Features - Extended operating temperature range of -40℃ to 70℃, Fan-less aluminum case filled with heat conductive glue, Able to withstand 10G vibration, Power on LED indicator, Short Circuit, Over Current, Over Voltage, and Over Temperature Protections, & Adjustable output through potentiomete

DA60U-240A-R

- Output Power - 60W

- Output Volt - 24V

- Output Current - 2.5A

- # of ports - 1

- Features - RESNA Compliant, CEC Compliant, LED Indicators Charge State, OVP, OTP, SCP, Charges AGM Batteries, Max 12hrs Charging Time

DA200U-250A-R

- Output Power - 200W

- Output Volt - 24V

- Output Current - 8A

- # of ports - 1

- Features - RESNA Compliant, CEC Compliant, LED Indicators Charge State, OVP, OTP, SCP, Dual-Mode Charger, Charges GEL or AGM batteries, Max 12hrs Charging Time

How should OEMs evaluate DC/DC converter topologies for industrial and medical use?

Evaluating DC/DC converter topology is one of the most important decisions OEMs make when designing power systems. Topology determines how the converter handles isolation, noise, efficiency, and thermal behavior. In industrial and medical applications, these factors directly affect system reliability and safety. OEMs must consider whether isolated or non-isolated converters are appropriate for each voltage domain and functional block.

Isolated DC/DC converters provide galvanic separation between input and output. This separation is often required in systems that interface with external sensors, communication buses, or patient-connected devices. Isolation helps eliminate ground loops, reduce EMI coupling, and protect downstream electronics from hazardous voltages. In medical systems, isolation is frequently mandated by safety standards. In industrial systems, isolation improves robustness in environments with long cable runs and mixed grounding conditions.

Non-isolated converters offer advantages in efficiency, size, and cost. They are commonly used for internal voltage regulation where isolation is not required, such as point-of-load regulation on control boards or embedded modules. OEMs often combine both topologies in a single system, using isolation where safety or noise immunity is required and non-isolated converters for efficient local regulation.

Top Benefits

-

Enables correct balance between safety, efficiency, and cost

-

Reduces noise and grounding issues in complex systems

-

Supports mixed-voltage architectures with predictable behavior

Best Practices

-

Use isolated converters for externally connected or safety-critical circuits

-

Apply non-isolated converters for internal low-voltage regulation

-

Validate topology choices against applicable safety standards

Careful topology evaluation ensures that DC/DC converters support both functional requirements and regulatory expectations without unnecessary complexity.

What factors influence DC/DC converter reliability in harsh industrial and medical environments?

Reliability in industrial and medical environments depends on how well DC/DC converters handle real-world stress. These environments often expose electronics to elevated temperatures, electrical noise, vibration, humidity, and continuous operation. A converter that performs well in laboratory testing may behave very differently once installed in a sealed enclosure or a high-duty-cycle system.

Thermal performance is one of the most critical factors. As ambient temperature rises, converters may derate output power to prevent overheating. OEMs must understand thermal derating curves and ensure sufficient power margin at worst-case conditions. Efficiency also plays a major role. Higher efficiency reduces heat generation, which improves component lifespan and delays thermal derating.

EMI and EMC behavior is another reliability driver. Poorly controlled switching noise can interfere with sensors, communication links, or diagnostic circuitry. In medical systems, electrical noise can compromise measurement accuracy or trigger compliance failures. Mechanical factors such as vibration and shock also influence long-term stability, particularly in industrial equipment.

Top Benefits

-

Improves uptime in continuous operation environments

-

Reduces field failures caused by thermal or electrical stress

-

Supports consistent performance across global deployments

Best Practices

-

Evaluate thermal derating inside the final enclosure

-

Select converters with proven EMI and EMC performance

-

Design with electrical and thermal headroom for aging effects

Reliability-focused evaluation helps OEMs avoid premature failures and ensures DC/DC converters perform consistently throughout the product lifecycle.

CLIENT'S QUOTE

Phihong's Power-Over-Ethernet solutions have transformed our network, boosting efficiency and reducing costs. Their seamless integration has simplified both installation and maintenance.

How DC/DC converter form factor affects scalability and system architecture

DC/DC converter form factor plays a critical role in how power systems scale, dissipate heat, and evolve over time. OEMs commonly choose between board-mount converters and brick style converters based on power level, enclosure constraints, serviceability, and future expansion needs. This decision influences not only PCB layout but also thermal strategy, maintenance access, and long term product flexibility.

Board-mount DC/DC converters are typically used in distributed power architectures where regulation occurs close to the load. They are ideal for embedded controllers, sensors, communication modules, and multi-rail designs that require compact integration. Their proximity to sensitive electronics improves transient response and reduces voltage drop, but thermal dissipation is limited by PCB copper area and airflow. As power density increases, board-mount converters may derate earlier, especially in sealed or fanless enclosures.

Brick DC/DC converters are designed for higher power delivery and centralized or intermediate bus architectures. Their larger form factor allows better heat dissipation through baseplates, heat sinks, or forced airflow. Brick converters also support standardized footprints, which simplifies upgrades and sourcing over long product lifecycles. OEMs building industrial control cabinets, networking platforms, or medical imaging systems often rely on brick converters to establish a stable power backbone.

Top Benefits

-

Aligns power architecture with system scalability goals

-

Improves thermal predictability at higher power levels

-

Supports long term serviceability and upgrade paths

Best Practices

-

Use board-mount converters for localized low to medium power rails

-

Choose brick converters for centralized or high power stages

-

Evaluate enclosure airflow and service access early

Selecting the appropriate form factor allows OEMs to design power systems that scale cleanly as performance, power, and lifecycle requirements evolve.

Managing EMI, EMC, and safety at the DC/DC converter level

EMI, EMC, and safety challenges are unavoidable in modern DC/DC converter designs, particularly in industrial and medical systems. High frequency switching generates conducted and radiated noise that can interfere with sensors, communication buses, and control logic. In regulated environments, failure to manage this noise can result in certification delays or field reliability issues.

OEMs must address EMI at multiple levels. Converter topology, switching behavior, PCB layout, filtering, grounding, and isolation all influence emissions. Isolated DC/DC converters help break noise paths and protect sensitive circuits from ground potential differences. Proper filtering at the input and output prevents noise from propagating through power rails or external cables. Grounding strategies must ensure predictable return paths for high frequency currents.

Safety requirements add another layer of complexity. Medical and industrial standards specify isolation voltage, creepage, clearance, and leakage current limits. These requirements affect both component selection and system architecture. OEMs that evaluate EMI and safety together achieve better outcomes than those treating them as separate problems.

Top Benefits

-

Improves first pass EMC certification success

-

Protects users and equipment from electrical hazards

-

Enhances signal integrity in noisy environments

Best Practices

-

Address EMI and safety early in system design

-

Use isolation where external connections or hazardous voltages exist

-

Validate emissions and grounding in the final enclosure

Managing EMI, EMC, and safety at the converter level reduces downstream risk and supports reliable, compliant product deployment.

Thermal derating and efficiency define real world DC/DC converter reliability

Thermal derating and efficiency ultimately determine how DC/DC converters behave outside the lab. As ambient temperature rises, converters must reduce output power to stay within safe operating limits. OEMs that design systems based only on nominal ratings often encounter unexpected brownouts or resets when converters derate under real conditions.

Efficiency is a primary driver of thermal performance. Higher efficiency means less power is lost as heat, which delays derating and reduces stress on internal components. In compact designs, even small efficiency improvements can significantly increase usable power. OEMs must consider efficiency across the full load range and at elevated temperatures, not just at peak load under ideal conditions.

Thermal behavior is also influenced by enclosure design, airflow, and component placement. Validating derating inside the final housing is essential. Systems that operate continuously or in harsh environments require additional thermal margin to account for aging, dust buildup, and worst case operating scenarios.

Top Benefits

-

Prevents unexpected power loss at elevated temperatures

-

Improves long term reliability and component lifespan

-

Reduces field failures caused by thermal overstress

Best Practices

-

Size converters using worst case ambient temperatures

-

Review derating curves during power budgeting

-

Design with thermal headroom for continuous operation

Understanding thermal derating and efficiency tradeoffs allows OEMs to design DC/DC power systems that remain stable, predictable, and reliable throughout the product lifecycle.

How Phihong supports OEM DC/DC converter design for industrial and medical systems

Phihong supports OEMs with a broad portfolio of DC/DC converter solutions designed for reliability, efficiency, and compliance in demanding industrial and medical environments. Their offerings include isolated and non isolated converters, board mount and brick form factors, and designs optimized for EMI control, thermal performance, and long term stability. This allows OEMs to select power solutions that align precisely with system architecture, safety requirements, and enclosure constraints.

Phihong designs DC/DC converters with predictable thermal derating behavior and high efficiency across load ranges. This helps OEMs maintain stable output power in compact designs and elevated ambient conditions. Their isolated solutions provide robust galvanic separation for noise sensitive, safety critical, or externally connected circuits, while non isolated options deliver high efficiency for internal voltage regulation.

Beyond hardware, Phihong provides engineering guidance, documentation, and global compliance support. OEMs benefit from clear datasheets, consistent manufacturing quality, and long product lifecycles that reduce redesign risk. Whether designing industrial control systems, medical equipment, robotics platforms, or embedded electronics, Phihong helps OEMs build reliable power architectures that scale across markets and operating conditions.

Suggested links

https://www.phihong.com/internal-power-supply/

https://www.phihong.com/contact/

FEATURED RESOURCE

Phihong's Power-Over-Ethernet solutions have transformed our network, boosting efficiency and reducing costs.

FAQ

What makes DC/DC converters critical to reliability in industrial and medical equipment?

DC/DC converters play a central role in determining system reliability because they directly regulate voltage delivered to sensitive electronics. In industrial environments, converters must withstand electrical noise, voltage transients, temperature extremes, and continuous operation. In medical systems, they must also meet strict safety and leakage current requirements while maintaining stable, low noise power delivery. If a DC/DC converter fails or behaves unpredictably, the entire system can experience resets, data corruption, inaccurate measurements, or safety compliance issues.

Reliability depends on several factors including converter topology, efficiency, thermal performance, EMI behavior, and isolation. A converter that operates near its thermal limits or generates excessive noise may pass initial testing but fail over time in real deployments. Aging effects such as capacitor degradation further increase stress if insufficient margin is designed in.

OEMs improve reliability by selecting DC/DC converters based on worst case conditions rather than nominal ratings. This includes accounting for elevated ambient temperatures, continuous duty cycles, enclosure airflow limitations, and long term aging. Converters that maintain stable performance across these variables form the foundation of reliable industrial and medical equipment.

How do isolated and non isolated DC/DC converters affect system safety and noise immunity?

Isolated DC/DC converters provide galvanic separation between input and output, which protects users and downstream electronics from hazardous voltages and ground potential differences. This is especially important in industrial systems with long cable runs, mixed grounding conditions, or exposure to high voltage transients. In medical equipment, isolation is often mandatory to meet safety standards and limit leakage current near patients.

Non isolated DC/DC converters do not provide galvanic separation but offer advantages in efficiency, size, and cost. They are well suited for internal voltage regulation where safety isolation is not required. However, without isolation, noise can couple more easily between subsystems if grounding and layout are not carefully managed.

OEMs often use both types within a single system. Isolation is applied where safety or noise immunity is required, while non isolated converters handle efficient point of load regulation. Choosing the correct topology for each power domain improves safety, reduces EMI risk, and simplifies compliance.

Why do thermal derating and efficiency matter more in compact DC/DC designs?

Compact DC/DC converters operate at higher power density, which makes thermal management more challenging. As temperature rises, converters must reduce output power to prevent overheating. This behavior is defined by thermal derating curves. If OEMs ignore derating, systems may experience brownouts or shutdowns under elevated ambient conditions.

Efficiency directly affects thermal behavior. Lower efficiency means more power is converted into heat, which accelerates derating and stresses internal components. In compact enclosures with limited airflow, even small efficiency losses can significantly reduce usable power.

OEMs should evaluate efficiency across the full load range and at elevated temperatures. Selecting converters with higher efficiency and designing with thermal headroom allows compact systems to deliver reliable power without requiring oversized components or active cooling.

How do EMI and EMC considerations influence DC/DC converter selection?

DC/DC converters are a common source of EMI because of their high frequency switching behavior. Poorly controlled EMI can interfere with sensors, communication buses, and control logic. It can also cause products to fail EMC certification testing, delaying market entry.

Converter topology, switching frequency, layout, filtering, grounding, and isolation all influence EMI performance. Isolated converters help block noise paths and ground loops. Proper filtering prevents conducted emissions from spreading through power rails or cables. Layout discipline ensures high frequency currents follow predictable return paths.

OEMs that consider EMI early in DC/DC converter selection reduce reliance on late stage fixes such as shielding or ferrites. This results in more predictable compliance outcomes and more stable system behavior.

How should OEMs approach long term lifecycle and compliance when selecting DC/DC converters?

Long term lifecycle considerations are critical for industrial and medical equipment, which often remain in production and service for many years. OEMs must consider component availability, standardized footprints, supplier stability, and regulatory consistency when selecting DC/DC converters.

Compliance requirements can evolve over time, and converters must maintain certification consistency across production runs. Using converters from manufacturers with strong documentation and global compliance expertise reduces the risk of forced redesigns or recertification delays.

OEMs should also plan for serviceability and scalability. Brick converters may support easier replacement or power upgrades, while board mount converters may require more careful upfront selection. A lifecycle focused approach ensures power systems remain viable, compliant, and supportable throughout the product lifespan.