BLOG

How Should OEMs Choose Between Isolated and Non-Isolated DC/DC Converters for Industrial Control Systems?

QUICK LINKS

Why do industrial control systems require both isolated and non-isolated DC/DC converter options?

Industrial control systems support a wide range of applications—from motor drives and PLCs to sensors, communication modules, robotic actuators, and embedded computing. Because these systems operate under varying electrical and environmental conditions, OEMs must understand when to use isolated vs non-isolated DC/DC converters. Each topology plays a specific role in protecting equipment, stabilizing voltage, and ensuring system-wide safety. Choosing the wrong converter can lead to noise issues, ground loop problems, component failures, or even hazardous conditions.

Isolated DC/DC converters provide galvanic separation between input and output, making them essential in high-voltage systems, noisy industrial environments, or applications requiring operator safety or functional isolation. Non-isolated converters, on the other hand, offer higher efficiency, smaller size, and lower cost—ideal for distributed electronics where isolation isn’t required. Industrial systems often blend both types, using isolation where safety or noise protection is needed and non-isolated converters where space and efficiency take priority.

Top Benefits

-

Supports flexibility across high-voltage, mixed-signal, and low-voltage control circuits

-

Reduces failures by matching converter topology to the electrical environment

-

Helps OEMs design scalable, safe, and compliant control architectures

Best Practices

-

Identify circuits needing galvanic isolation for safety or noise immunity

-

Use non-isolated converters for low-voltage subsystems to reduce cost

-

Evaluate environmental conditions that impact electrical noise

Understanding the need for both converter types helps OEMs build reliable industrial control systems that balance cost, safety, and performance.

(Suggested Links: Internal Power Supply Guide | Battery Chargers)

FEATURED PRODUCTS

AA03A-075A-R

- Output Power - 2.75W

- Output Volt - 7.5V

- Output Current - 0.366A

- Features - Fixed Blade AC Input, Limited Power Source, Class B EMI, Level VI Efficiency, Standard Barrel Connector

AC Series

- Output Current - 16A

- Features - Mode 2-chargers can use a circuit ranging from 8Amp to 16Amp with a local standard AC input plug installed for operation, Provides overcurrent, over voltage and short circuit protection, Protected against strong jets of water from all directions, Continuously monitors/supervises the ground connection between the AC supply and EV to ensure safe and reliable charging

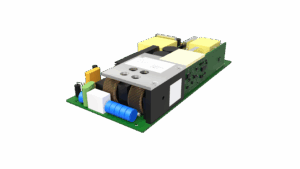

BF550-234A-R

- Output Power - 550W

- Output Volt - 12Vdc / 54.5Vdc

- Features - Universal AC Input range, Class I Design , Class B EMI , High Efficiency Performance , OVP, OCP, SCP, OTP Protections , Operating Altitude: 5,000M

DA1000Z-240AEV-R

- Output Power - 1000W

- Output Volt - 24V

- Output Current - 1000W

- Features - Extended operating temperature range of -40℃ to 70℃, Fan-less aluminum case filled with heat conductive glue, Able to withstand 10G vibration, Power on LED indicator, Short Circuit, Over Current, Over Voltage, and Over Temperature Protections, & Adjustable output through potentiomete

DA60U-240A-R

- Output Power - 60W

- Output Volt - 24V

- Output Current - 2.5A

- # of ports - 1

- Features - RESNA Compliant, CEC Compliant, LED Indicators Charge State, OVP, OTP, SCP, Charges AGM Batteries, Max 12hrs Charging Time

DA200U-250A-R

- Output Power - 200W

- Output Volt - 24V

- Output Current - 8A

- # of ports - 1

- Features - RESNA Compliant, CEC Compliant, LED Indicators Charge State, OVP, OTP, SCP, Dual-Mode Charger, Charges GEL or AGM batteries, Max 12hrs Charging Time

What is the difference between isolated and non-isolated DC/DC converters in industrial applications?

Isolated DC/DC converters use a transformer to provide electrical separation between input and output. This isolation protects sensitive downstream electronics from high-voltage spikes, eliminates ground loop noise, and ensures safety where circuits connect to operators, sensors, or external equipment. Isolation is critical when controlling motors, interfacing with hazardous voltages, or integrating fieldbus communication modules susceptible to electrical interference.

Non-isolated DC/DC converters do not provide galvanic isolation but offer advantages in efficiency, compact size, lower weight, and reduced BOM cost. These converters are ideal for low-voltage rails, distributed control boards, communication modules, and embedded systems with stable, clean input sources. They are commonly used for onboard regulation in PLCs, HMIs, IoT devices, and robotics controllers.

OEMs should evaluate system architecture, grounding schemes, voltage domains, and safety requirements when choosing between topologies. Some industrial designs require both: isolation for external-facing circuitry and non-isolated converters for onboard voltage regulation.

Top Benefits

-

Clear distinction helps OEMs match converter to system behavior

-

Prevents costly redesigns caused by noise or grounding issues

-

Supports long-term reliability across varied load and voltage environments

Best Practices

-

Use isolated converters in high-voltage or noisy installations

-

Choose non-isolated converters for compact multi-rail power systems

-

Validate EMI/EMC performance early in the design cycle

Knowing when to isolate and when not to ensures predictable system behavior, stable power delivery, and long-term industrial reliability.

(Suggested Links: Open-Frame Power Supplies | PoE Injectors)

When should OEMs choose isolated DC/DC converters for industrial control environments?

OEMs typically choose isolated DC/DC converters when electrical separation is required to prevent hazardous voltages from transferring to sensitive circuits or user-accessible interfaces. Isolation is essential when designing systems that include motors, actuators, outdoor sensors, long cable runs, or equipment connected to unknown external wiring. In these cases, isolation prevents safety hazards, protects low-voltage electronics from surges, and reduces electromagnetic interference that can cause erratic control behavior.

Isolation is also crucial in mixed-signal systems. For example, analog measurement circuits often need isolation to avoid ground reference conflicts, while communication interfaces like RS-485, CAN, and industrial Ethernet benefit from isolation to eliminate noise coupling. Medical industrial environments or cleanroom automation systems may also require isolation to meet safety approvals and functional reliability standards.

Top Benefits

-

Protects devices from high-voltage faults and ground loops

-

Enhances noise immunity in electrically noisy environments

-

Ensures compliance with safety and industrial communication standards

Best Practices

-

Evaluate isolation voltage, creepage, and clearance distances

-

Confirm compliance with IEC/UL isolation requirements

-

Use isolated converters for externally connected or field wiring circuits

Choosing isolated converters in the right places strengthens system safety, improves uptime, and prevents electrical hazards that could compromise industrial operations.

(Suggested Links: Medical Power Supplies | Innovations in Medical Power Design)

CLIENT'S QUOTE

Phihong's Power-Over-Ethernet solutions have transformed our network, boosting efficiency and reducing costs. Their seamless integration has simplified both installation and maintenance.

Non-isolated converters improve efficiency and reduce system cost for multi-rail electronics

Non-isolated DC/DC converters are widely used in distributed power architectures because of their high efficiency, compact size, and lower cost. In industrial control systems, controllers, sensor modules, communication boards, and HMI devices often require multiple voltage rails derived from a single 24V or 48V bus. Non-isolated converters excel in these scenarios because they waste less energy, generate less heat, and can be placed directly on PCB assemblies without additional isolation components.

Their simplicity makes them ideal for space-constrained enclosures, DIN-rail modules, and IoT gateways where power density is crucial. Without a transformer, non-isolated converters achieve higher conversion efficiency and faster transient response, supporting more stable operation during dynamic load changes. For OEMs looking to reduce BOM cost, streamline PCB layout, and improve thermal performance, non-isolated designs provide a cost-effective and reliable solution.

Top Benefits

-

High efficiency reduces heat buildup in sealed enclosures

-

Lower cost and smaller footprint improve product design flexibility

-

Faster transient response supports stable electronics performance

Best Practices

-

Use non-isolated converters for secondary low-voltage rails

-

Validate thermal performance under worst-case continuous load

-

Pair with proper input filtering for noisy power buses

Non-isolated converters support efficient, scalable multi-rail architectures that help OEMs minimize costs while maintaining excellent electrical performance across industrial systems.

(Suggested Links: USB Power Delivery | Internal Power Supply Guide)

Isolation enhances safety, noise immunity, and regulatory compliance in harsh industrial environments

Isolation is not just an electrical design choice—it is often a regulatory and safety requirement. Industrial environments expose electronics to high-voltage transients, ground potential differences, and unpredictable field wiring conditions. Isolated DC/DC converters create a protected electrical boundary between subsystems, preventing dangerous energy transfer and ensuring compliance with standards such as IEC 60601-1 (for medical), IEC 62368-1 (for ICT/industrial), and IEC 61010-1 (for laboratory and measurement equipment).

Isolation dramatically improves noise immunity, making it essential in systems exposed to motors, solenoids, switching relays, or long communication cables. Without proper isolation, noise can couple into sensitive analog circuits or cause digital misbehavior in PLCs, sensors, and communication modules. OEMs deploying equipment outdoors or across large facilities rely on isolation to keep ground loops from destabilizing system performance.

Top Benefits

-

Meets safety regulations for high-voltage or operator-accessible circuits

-

Reduces EMI issues in motor-driven or heavy industrial environments

-

Prevents damage from transients and ground potential differences

Best Practices

-

Review isolation voltage ratings and safety standard compliance

-

Match creepage/clearance to pollution degree and overvoltage category

-

Use isolation where long cable runs or field wiring are involved

For OEMs building industrial systems that must endure noise, voltage spikes, or safety scrutiny, isolation is a crucial design element that ensures longevity, reliability, and regulatory compliance.

(Suggested Links: Medical Power Supplies | PoE Injectors)

Choosing the right topology ensures long-term reliability, safety, and global product readiness

DC/DC converter topology selection is a strategic decision that shapes how industrial equipment performs over time. The right choice balances cost, efficiency, safety, EMI behavior, environmental stress, and certification pathways. OEMs must consider not only the electrical characteristics of each converter type but also the expected field conditions—temperature, vibration, humidity, cable distances, and exposure to motors or switching equipment.

Selecting isolated or non-isolated converters affects thermal management, board layout, regulatory testing, and product lifecycle stability. Many reliability issues arise when an inappropriate converter topology is used—for example, loss of signal integrity in noisy environments, insufficient protection during transients, or long-term failures due to thermal stress. By carefully aligning converter choice with the application’s operational realities, OEMs can prevent costly field failures and ensure smooth certification across global regions.

Top Benefits

-

Enhances system uptime and long-term durability

-

Supports compliance and reduces certification risk

-

Ensures stable electrical behavior under real-world load conditions

Best Practices

-

Map converter topology to safety and noise categories early in design

-

Validate full-load and transient performance inside real enclosures

-

Use experienced power supply vendors to avoid topology mismatches

Correct topology selection is the foundation of reliable industrial system design. OEMs that evaluate their electrical environment holistically build safer, more robust, and globally deployable equipment.

(Suggested Links: Open-Frame Power Supplies | Battery Chargers)

How Phihong supports OEMs choosing isolated and non-isolated DC/DC converters

Phihong provides OEMs with a wide range of DC/DC converters engineered for industrial control systems that demand long-term reliability, safety compliance, and stable performance under noisy or unpredictable electrical conditions. Their isolated solutions support high-voltage, mixed-signal, and field-wiring applications, offering robust galvanic isolation, strong noise immunity, and compliance with IEC/UL standards. Phihong’s non-isolated converters deliver high efficiency, compact size, and low thermal output—ideal for distributed embedded electronics, multi-rail control boards, and cost-sensitive industrial designs.

OEMs benefit from Phihong’s engineering guidance during early system design, helping teams determine precise isolation requirements, evaluate transient behavior, and verify real-world environmental suitability. Documentation, compliance reports, and global certifications simplify integration and accelerate regulatory approval. With proven manufacturing consistency and long product lifecycles, Phihong ensures OEMs can scale their industrial equipment across markets without redesign concerns.

Whether an OEM is developing industrial automation systems, robotics platforms, communication modules, PLCs, or medical-adjacent equipment, Phihong delivers DC/DC power solutions built for safety, efficiency, and global readiness.

(Suggested Links: Internal Power Supply Guide | Contact Phihong)

FEATURED RESOURCE

Phihong's Power-Over-Ethernet solutions have transformed our network, boosting efficiency and reducing costs.

FAQ

What factors should OEMs consider when deciding between isolated and non-isolated DC/DC converters?

OEMs should begin by evaluating the electrical environment and safety requirements of the target application. If the system interfaces with high voltage, field wiring, motors, actuators, or external sensors, isolated converters are typically necessary to provide galvanic separation and prevent dangerous energy transfer. Isolation is also essential for reducing noise in mixed-signal systems, supporting communication protocols like RS-485 or CAN, and meeting regulatory approvals for safety-critical equipment.

Next, OEMs must evaluate whether downstream components require their own voltage rails. In multi-rail designs, non-isolated converters often provide cost-efficient regulation with higher efficiency and smaller footprints. These converters excel in low-voltage local regulation within PLCs, HMI panels, IoT nodes, and embedded control boards. They generate less heat and fit well in dense electronic assemblies.

Environmental conditions also influence the decision. Harsh industrial or high-EMI environments almost always benefit from isolation, while compact, thermally constrained enclosures favor non-isolated designs for efficiency reasons.

Considering safety, noise immunity, cost, efficiency, and system architecture holistically enables OEMs to choose the correct topology for long-term device reliability and global compliance.

Why is galvanic isolation so important in industrial control systems?

Galvanic isolation protects sensitive electronics and human operators from dangerous voltages, electrical faults, and ground potential differences. In industrial facilities, motors, relays, switching equipment, and long cable runs create unpredictable electrical conditions. Without proper isolation, transients can jump into low-voltage circuits, causing equipment failure, signal distortion, or unsafe operating conditions. Galvanic separation ensures that a failure in one part of the system does not propagate into other subsystems.

Isolation also improves noise immunity. Industrial control systems often include sensors, analog measurement circuits, and communication lines prone to interference. Isolated converters eliminate ground loops, a common source of erratic analog readings and communication instability. Protocols like Modbus, RS-485, CAN, and Ethernet in harsh environments often require isolation to prevent voltage offsets from damaging transceivers.

Regulatory compliance is another major driver. Standards such as IEC 62368-1, IEC 61010-1, and IEC 60601-1 require isolation for certain categories of equipment. Meeting these standards at the power-converter level greatly simplifies the certification process for OEM devices.

In short, galvanic isolation is not optional—it is a foundational safety and performance requirement in modern industrial control design.

How do non-isolated converters improve efficiency and reduce thermal load in embedded systems?

Non-isolated converters offer higher efficiency because they eliminate transformer-based isolation stages, allowing more energy to transfer directly from input to output. This results in lower power loss and less heat generation, which is critical in embedded electronics where airflow is limited, enclosures are compact, and components are tightly packed. Lower heat output not only improves reliability but also extends component lifespan and reduces EMI emissions that may affect sensitive circuits.

Their compact size makes them ideal for PCB-level voltage regulation in multi-rail systems. For example, a 24V input powering a PLC may require 12V, 5V, and 3.3V rails. Non-isolated converters can be placed directly next to their loads, reducing trace lengths, improving transient response, and minimizing voltage drops. These efficiencies translate into smaller PCBs, lower BOM cost, and easier assembly.

Because they are simpler and cheaper than isolated converters, non-isolated designs help OEMs optimize cost-sensitive products while maintaining high performance. By reducing thermal challenges and supporting higher density layouts, they improve system sustainability and long-term stability.

What common mistakes do OEMs make when selecting DC/DC converters for industrial applications?

A frequent mistake is overlooking environmental conditions. OEMs often select converters based on nominal lab performance without fully considering temperature rise inside sealed housings, vibration in motion systems, or humidity exposure in field installations. Derating curves are ignored, leading to premature failures once the device enters real-world use.

Another mistake is inadequate noise and EMI evaluation. Industrial environments introduce electrical noise that non-isolated converters may not tolerate without additional filtering. Conversely, OEMs may over-specify isolation where it isn’t needed, increasing cost unnecessarily.

Some teams misjudge current requirements by underestimating dynamic load spikes—particularly in motor control, communication bursts, or sensor activation cycles. This can result in converter overload or instability.

Finally, inadequate documentation review can lead to certification delays. Safety approvals, isolation ratings, and compliance details are often overlooked until late in development, creating redesigns that cost time and money.

Avoiding these pitfalls requires careful review of real operating conditions, system architecture, and long-term reliability expectations.

Why should OEMs trust Phihong for isolated and non-isolated DC/DC converter solutions?

Phihong brings decades of power engineering expertise, providing globally certified DC/DC solutions designed for industrial, medical, and automation environments. Their isolated converters deliver reliable galvanic separation, high noise immunity, and compliance with IEC/UL requirements—essential for safe interfacing with field wiring, high-voltage systems, and sensitive communication lines. Their non-isolated converters offer exceptional efficiency, compact footprints, and stable voltage regulation for multi-rail electronics and embedded control applications.

OEMs rely on Phihong because of their consistent manufacturing quality, detailed datasheets, long-term availability, and engineering support. Phihong helps OEMs evaluate topology requirements, interpret isolation ratings, and validate performance under realistic load and environmental conditions. Their broad product portfolio allows OEMs to scale across global markets with minimal redesign effort and maximum reliability assurance.

Phihong’s combination of technical depth, global compliance expertise, and customer-focused support makes them a trusted partner for OEMs building next-generation industrial control systems.